Hydraulic supply device and control method

A technology of hydraulic supply and hydraulic circuit, applied in the direction of transmission control, transmission parts, components with teeth, etc., can solve problems such as increased fuel consumption, increased wear of transmission components, single operating point, etc., and achieves improved shifting. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

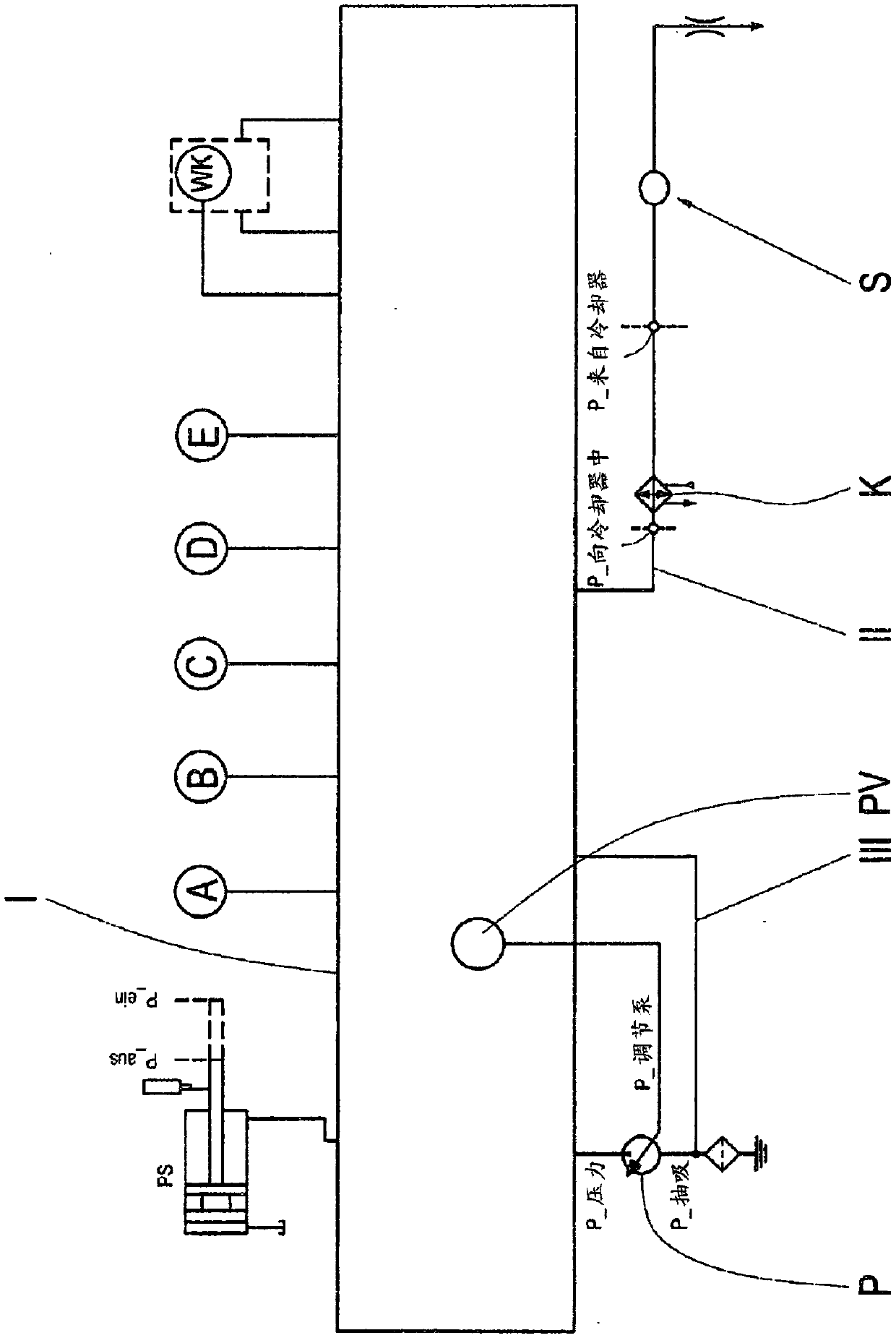

[0023] The supply device comprises a primary hydraulic circuit I for supplying the transmission components, for example shift elements A, B, C, D, E and the hydrodynamic coupling WK, as well as the parking lock PS.

[0024] The shifting elements A to E are supplied with hydraulic pressure via the primary hydraulic circuit I so that they can be engaged or disengaged. Furthermore, the fluid coupling and the parking lock PS are supplied with hydraulic medium in order to be engaged or disengaged by means of the engagement pressure Pein and the disengagement pressure Paus.

[0025] Furthermore, the supply device comprises a secondary hydraulic circuit II, which is supplied with hydraulic medium for lubricating and cooling the transmission components. A cooling device K is provided in the secondary hydraulic circuit II, from which it is supplied with a pressure p_zK, which is measured upstream of the cooler in the direction of flow. The hydraulic medium with the pressure p_vK measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com