Silicon-copper composite material, preparation method and application in lithium ion battery

A composite material, copper sheet technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex process, high chemical vapor deposition cost, unfavorable large-scale production of products, etc., and achieve the effect of overcoming large-scale separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

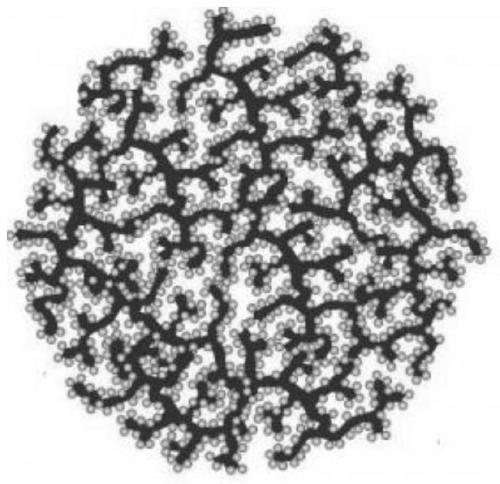

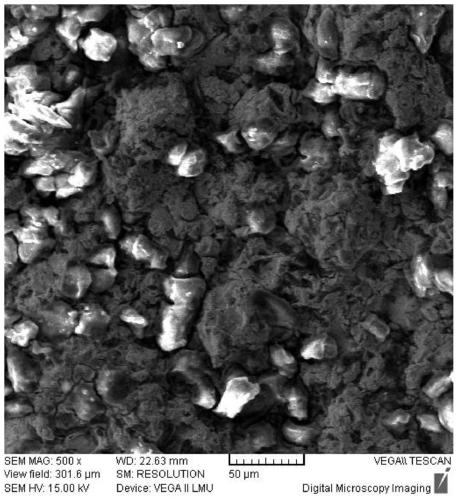

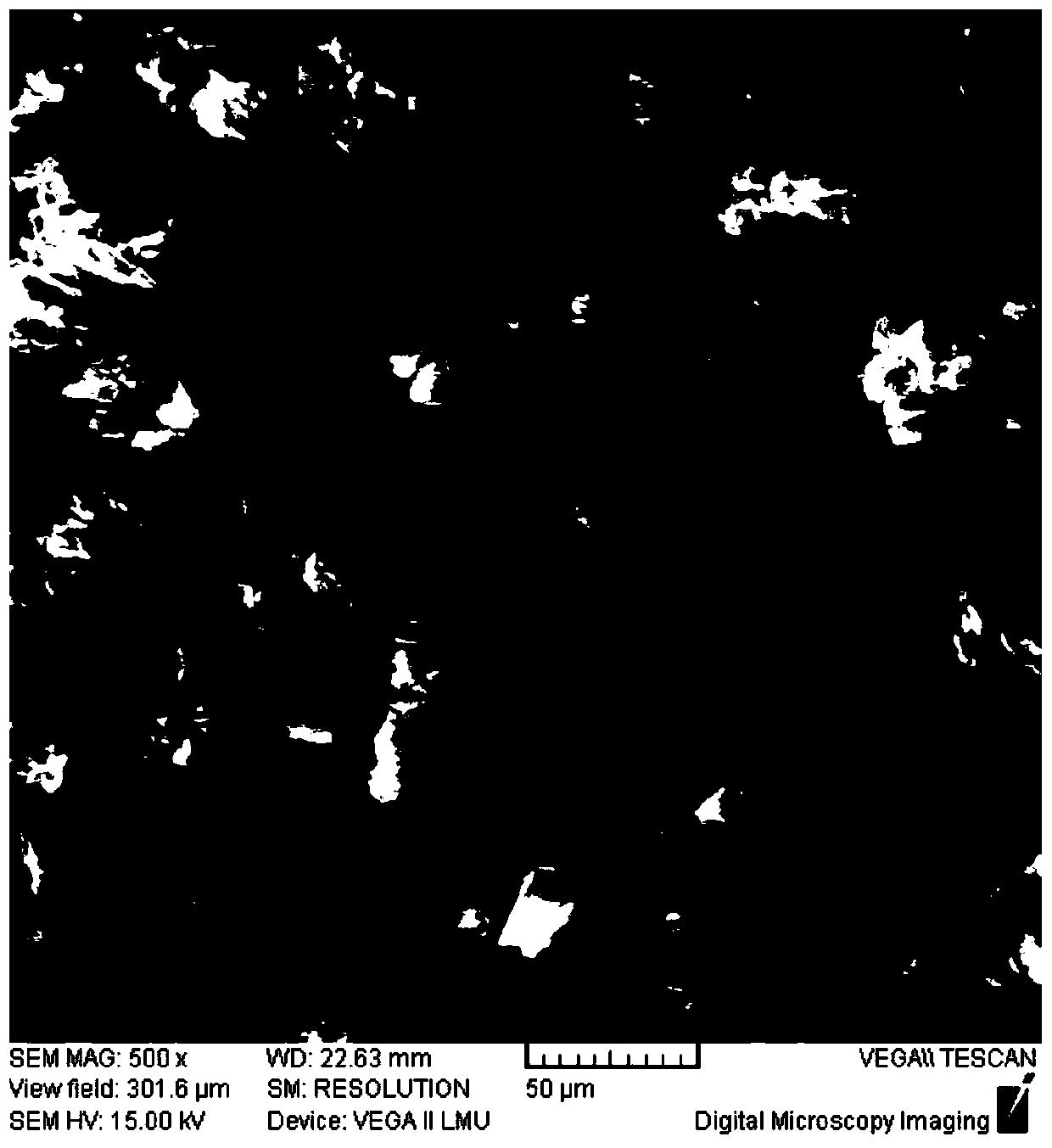

Image

Examples

Embodiment 1

[0035]In this embodiment, a silicon-copper composite material is specifically prepared through the following steps: first, a copper sheet with a thickness of 500 μm is selected as a substrate, and the copper sheet is polished and polished by a grinding machine until the roughness is 0.05; Pure silicon wafers were placed in a high-energy ball mill, ground for 20 minutes, filtered through a 270-mesh sieve for 2 hours, and then filtered through a 300-mesh sieve for 2 hours to obtain silicon particles with an average particle size of about 50 μm. Use a cold spray powder feeder to spray silicon particles on the surface of the substrate. Before spraying, you need to empty the cold spray powder feeder and the nozzle. The specific method is: first manually clean it, and then let the cold spray machine idle for 30 minutes. Next, add 500g of silicon particles to the cold spray powder feeder, adjust the speed of the sieve plate brush of the powder feeder to keep the powder output at 5g / mi...

Embodiment 2

[0038] In this embodiment, a silicon-copper composite material is specifically prepared through the following steps: first, a copper sheet with a thickness of 500 μm is selected as a substrate, and the copper sheet is polished and polished by a grinding machine until the roughness is 0.05; Pure silicon wafers were placed in a high-energy ball mill, ground for 30 minutes, filtered through a 270-mesh sieve for 2 hours, and then filtered through a 300-mesh sieve for 2 hours to obtain silicon particles with an average particle size of about 50 μm. Use a cold spray powder feeder to spray silicon particles on the surface of the substrate. Before spraying, you need to empty the cold spray powder feeder and the nozzle. The specific method is: first manually clean it, and then let the cold spray machine idle for 30 minutes. Next, add 500g of silicon particles to the cold spray powder feeder, adjust the speed of the sieve plate brush of the powder feeder to keep the powder output at 5g / m...

Embodiment 3

[0040] In this embodiment, a silicon-copper composite material is specifically prepared through the following steps: first, a copper sheet with a thickness of 500 μm is selected as a substrate, and the copper sheet is polished and polished by a grinding machine until the roughness is 0.05; Pure silicon wafers were placed in a high-energy ball mill, ground for 30 minutes, filtered through a 270-mesh sieve for 2 hours, and then filtered through a 300-mesh sieve for 2 hours to obtain silicon particles with an average particle size of about 50 μm. Use a cold spray powder feeder to spray silicon particles on the surface of the substrate. Before spraying, you need to empty the cold spray powder feeder and the nozzle. The specific method is: first manually clean it, and then let the cold spray machine idle for 30 minutes. Next, add 500g of silicon particles to the cold spray powder feeder, adjust the speed of the sieve plate brush of the powder feeder to keep the powder output at 5g / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com