Controllable semi-automatic tool

A semi-automatic cutting tool technology, applied in the direction of manufacturing tools, wood processing equipment, multi-purpose machinery, etc., can solve the problem of low cutting efficiency, achieve the effect of improving cutting efficiency, saving complicated steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

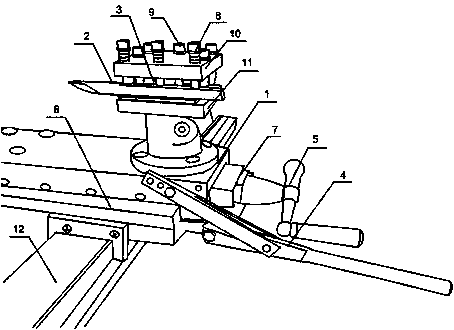

[0018] like figure 1 As shown, the present invention mainly includes a base 1, a blade 2, a cutter head 3, a slideway 6 and a hand pushing device, the hand pushing device is connected with the base 1 and the slideway 6 respectively, and the cutter head 3 is connected with the base 1, The base 1 is arranged on the slideway 6 , and the blade 2 is placed in the tool head 3 . The tool head 3 is placed on the base 1, the base 1 is set on the slideway 6, and the slideway 6 is placed on the clamping device or the guide rail 12 of the machine tool. Under the adjustment of the hand pushing device, the blade 2 is fixed in the tool head 3 and moves on the slideway 6 together with the base 1, so that the blade 2 is close to the wood for processing and polishing wood; in order to complete further processing, the hand pushing device is adjusted again , so that the cutter head 3 and the base 1 move on the clamping device or the guide rail 12 of the machine tool along with the slideway 6, so...

Embodiment 2

[0020] like figure 1 As shown, on the basis of Embodiment 1, the present embodiment includes a handle 5, a screw rod 7 and an automatic rod 4. The handle 5 is screwed to the slideway 6 through a bolt 7, and the automatic rod 4 is connected to the base 1 hinged connection. Rotate the handle 5, through the threaded cooperation between the screw rod 7 and the slideway 6, the base 1 moves along with the slideway 6 on the guide rail 12 of the machine tool or the clamping device; push the automatic rod 4 up and down to make the base 1 move on the slide Do linear motion on the road 6.

Embodiment 3

[0022] like figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the cutter head 3 includes an upper baffle 10 and a lower baffle 11, the lower baffle 11 is provided with a connecting column 9, and the upper baffle 10 is fixed on the connecting column 9, Fastening bolts 8 are arranged between the two plates, and the blade 2 is placed between the upper baffle 10 and the lower baffle 11 . The upper baffle 10 and the lower baffle 11 are fixed by the connecting column 9 to form a space, adjust the position of the blade 2, and then fix the blade 2 on the tool head 3 by rotating the fastening bolt 8; the fastening can be adjusted according to different situations Bolts 8 are used to replace blades 2 of different types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com