Hydrogen separating composite metal film with inlaid structure

A composite metal and hydrogen separation membrane technology, which is applied in the direction of hydrogen separation, separation method, semi-permeable membrane separation, etc., can solve the problems of thermal stress concentration, harsh preparation conditions and shedding of metal hydrogen separation membrane, and achieve the goal of overcoming thermal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

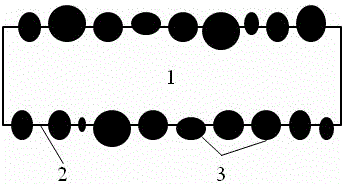

[0009] like figure 1 As shown, a part of metal palladium or palladium alloy is embedded in the surface of the film matrix material, while the other part is exposed on the surface, forming this special three-dimensional mosaic film structure.

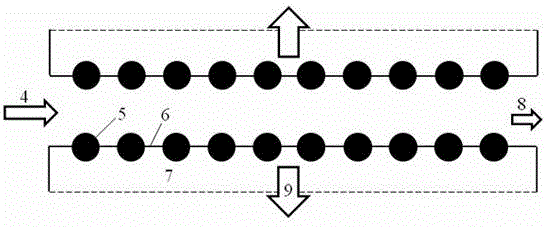

[0010] like figure 2 Shown is a schematic diagram of a simple hydrogen separator system. The mixed gas at the inlet 4 enters the separation channel, hydrogen is continuously decomposed and absorbed by palladium or palladium alloy particles 5, and pure hydrogen 9 passes through the substrate 7 to the other side to be absorbed Device collection. Other impurity gases with low hydrogen content flow out from the outlet 8 of the channel, so as to achieve the effect of separating and purifying hydrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com