Composite cathode pole piece of lithium ion battery and lithium ion battery thereof

A technology for lithium-ion batteries and negative pole pieces, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing battery capacity, reducing rate performance, and loss of lithium in positive pole piece materials, so as to improve the transmission rate and avoid Mutual interference, improve the effect of high temperature shelving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

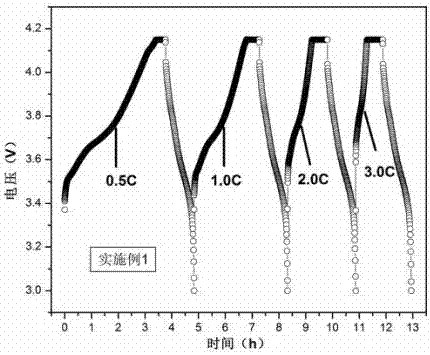

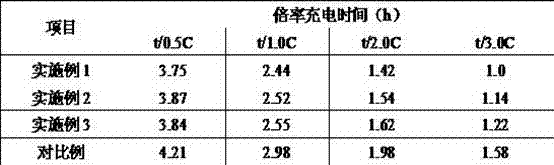

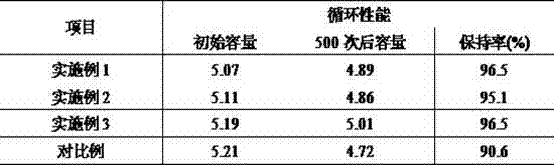

Embodiment 1

[0020] Preparation method of composite negative electrode sheet:

[0021] 1. Configuration of spraying liquid: Weigh 70g of polyvinylidene fluoride, 15g of carboxymethyl cellulose, and 15g of LA133 binder, add them to 500ml of N-methylpyrrolidone and disperse evenly to obtain a composite binder; weigh the above 30% weight of composite binder, and add 70g of lithium acetate, and disperse uniformly through a high-speed disperser to obtain an organic lithium spraying liquid; simultaneously weigh the above-mentioned 30% by weight of composite binder, and add 70g of lithium nitride, and disperse through a high-speed machine to disperse evenly to obtain inorganic lithium spraying liquid;

[0022] 2. Production of composite pole piece: Weigh 90g artificial graphite, 5gsp conductive agent and 5gLA133 binder, add it to 200g deionized water and disperse evenly to prepare negative electrode slurry, and prepare negative pole piece by coating. Spray the organic lithium spraying liquid on ...

Embodiment 2

[0024] 1. Configuration of spraying liquid: Weigh 60g of polyvinylidene fluoride, 20g of carboxymethyl cellulose, and 20g of LA133 binder, add them to 500ml of N-N-dimethylformamide and disperse evenly to obtain a composite binder; after that Weigh the above-mentioned 20% weight composite binder, and add 70g ethoxylithium, and disperse evenly through a high-speed disperser to obtain an organic lithium spraying liquid; simultaneously weigh the above-mentioned 20% weight composite binder, and add 70g Lithium amide, and uniformly dispersed by a high-speed disperser to obtain an inorganic lithium spraying liquid;

[0025] 2. Preparation of the composite pole piece: the preparation of the negative pole piece is the same as in Example 1.

[0026] Spray the organic lithium spraying liquid on one side of the negative electrode sheet by spraying technology, and after drying, obtain the electrode sheet A (dry thickness is 1 μm), and then spray the inorganic lithium spraying liquid on th...

Embodiment 3

[0028] 1. Configuration of spraying liquid: weigh 80g of polyvinylidene fluoride, 10g of carboxymethyl cellulose, and 10g of LA133 binder, add them to 500ml of tetrahydrofuran and disperse evenly to obtain a composite binder; then weigh the above 40% by weight Composite binder, and add 80g of alkyl dilithium carbonate, and disperse uniformly through a high-speed disperser to obtain an organic lithium spraying liquid; simultaneously weigh the above-mentioned 40% by weight of the composite binder, and add 80g of lithium amide, and disperse through a high-speed dispersion machine to disperse evenly to obtain inorganic lithium spraying liquid;

[0029] 2. Preparation of the composite pole piece: The preparation of the negative pole piece is the same as that in Example 1.

[0030] Spray the organic lithium spraying liquid on one side of the negative electrode sheet by spraying technology, and after drying, obtain the electrode sheet A (dry thickness is 5 μm), and then spray the ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com