Self-grinding non-toxic antifouling paint for hull bottoms and preparation method of self-grinding non-toxic antifouling paint

An anti-fouling paint, abrasive technology, applied in the field of paint, can solve problems such as inability to use on a large scale, bioaccumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

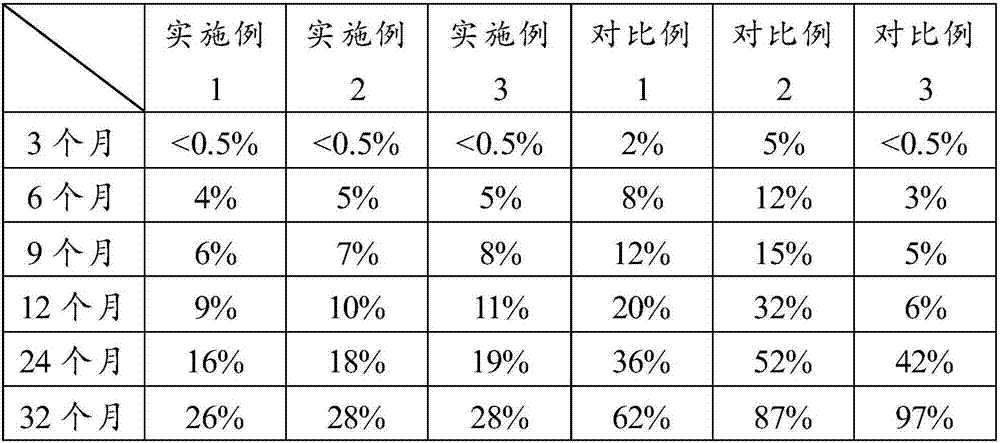

Examples

Embodiment 1

[0030] One, the preparation of modified resin composition

[0031] 1) Resin polymerization reaction: Add 5 parts by weight of styrene, 7 parts by weight of acrylonitrile, and 1 part by weight of methyl methacrylate to 15 parts by weight of toluene and heat to 78-82 °C, then add 0.3 parts by weight of catechol, 0.5 parts by weight of benzoyl peroxide was stirred and reacted; the temperature was raised to 120° C. for 2-3 hours at a heating rate of 5° C. / min;

[0032] 2) Preparation of the slow-release antifouling agent precursor: 3 parts by weight of sulfobutyl-β-cyclodextrin are dispersed in 8 parts by weight of dimethylformamide, the temperature is raised to 50°C and stirred, and then nano-sized cuprous oxide is added 2 parts by weight and 1.3 parts by weight of 2-methylimidazole were stirred, and the temperature was raised to 60° C. for 1-2 hours;

[0033] 3) The temperature of the reaction solution in step 1) is raised to reflux, and the solution in step 2) is added dropwis...

Embodiment 2

[0038] The preparation method of the modified resin composition is the same as in Example 1.

[0039] 2. Preparation of self-grinding non-toxic ship bottom antifouling coating

[0040] 1) Preparation of materials: Weigh 26 parts of modified resin composition, 10 parts of solvent, 2.8 parts of nano-sized cuprous oxide, 5 parts of hydroxyethyl cellulose, 0.3 part of hydroxypropyl guar gum, 2 parts of iron red, 4 parts of Glauber's salt Part; described solvent is made up of the composition of toluene, butanone and isopropyl acetate, and weight ratio is toluene: butanone: n-octanol=5:2:1;

[0041] 2) Preparation steps: Add the solvent in the formula amount into the high-speed disperser, then add the modified resin composition and nano-sized cuprous oxide and stir for 10 minutes; then add hydroxyethyl cellulose and hydroxypropyl guar gum and stir for 10 hours ; Finally, add iron red and Glauber's salt to disperse evenly, which is obtained from grinding non-toxic ship bottom antifoul...

Embodiment 3

[0043] The preparation method of the modified resin composition is the same as in Example 1.

[0044] 2. Preparation of self-grinding non-toxic ship bottom antifouling coating

[0045] 1) Preparation of materials: Weigh 31 parts of modified resin composition, 13 parts of solvent, 3.1 parts of nano-sized cuprous oxide, 6 parts of hydroxyethyl cellulose, 0.8 parts of hydroxypropyl guar gum, 3 parts of iron red, 6 parts of Glauber's salt Part; described solvent is made up of the composition of toluene, butanone and isopropyl acetate, and weight ratio is toluene: butanone: n-octanol=5:2:1;

[0046] 2) Preparation steps: Add the solvent in the formula amount into the high-speed disperser, then add the modified resin composition and nano-sized cuprous oxide and stir for 10 minutes; then add hydroxyethyl cellulose and hydroxypropyl guar gum and stir for 14 hours ; Finally, add iron red and Glauber's salt to disperse evenly, which is obtained from grinding non-toxic ship bottom antif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com