Rice cake demolding structure

A rice cake and demoulding technology, which is applied in food forming, food science, application, etc., can solve problems such as high viscosity of rice cake, affecting demoulding efficiency, and difficult demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

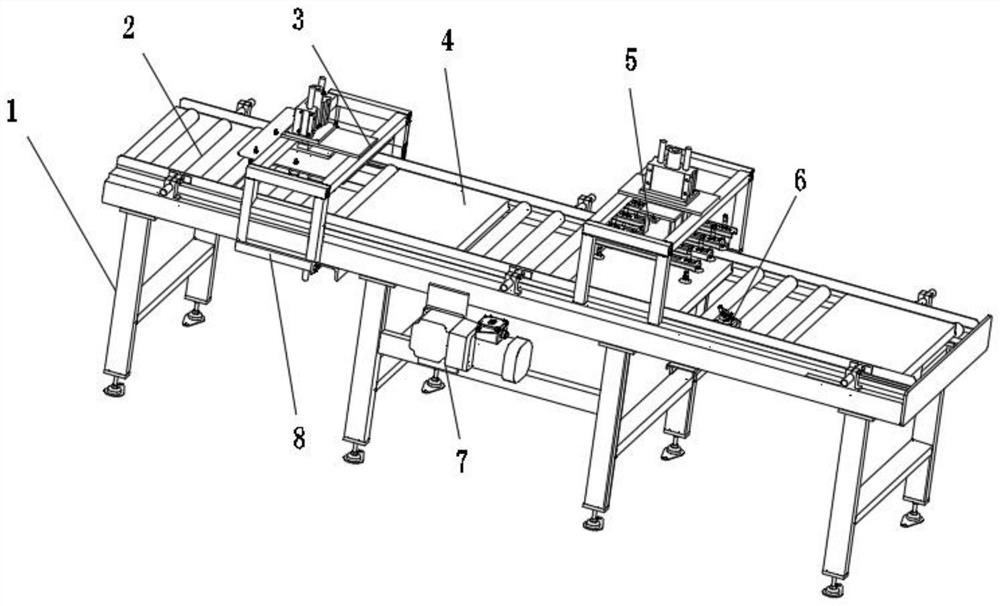

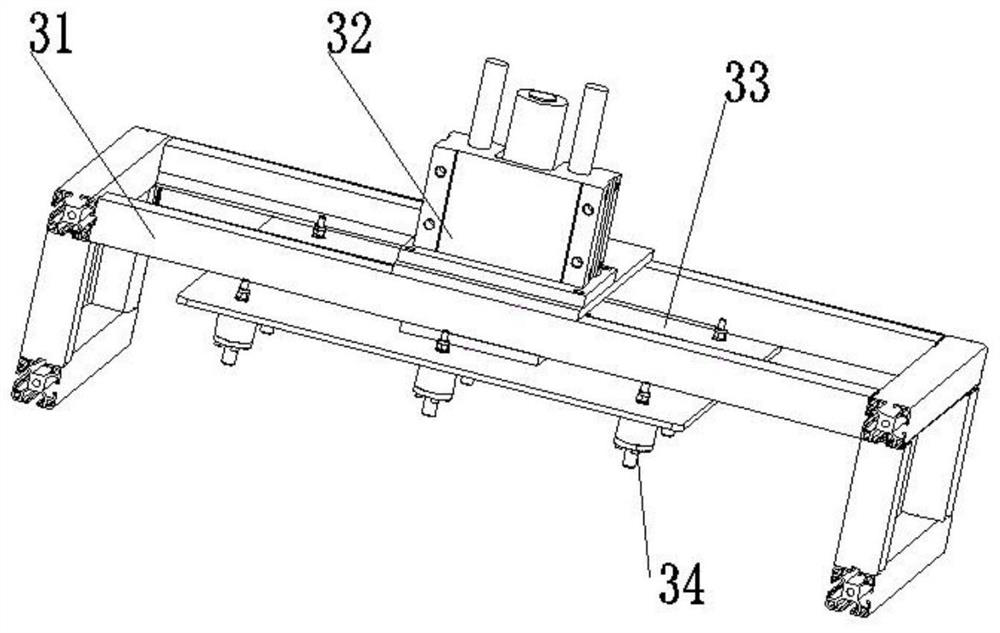

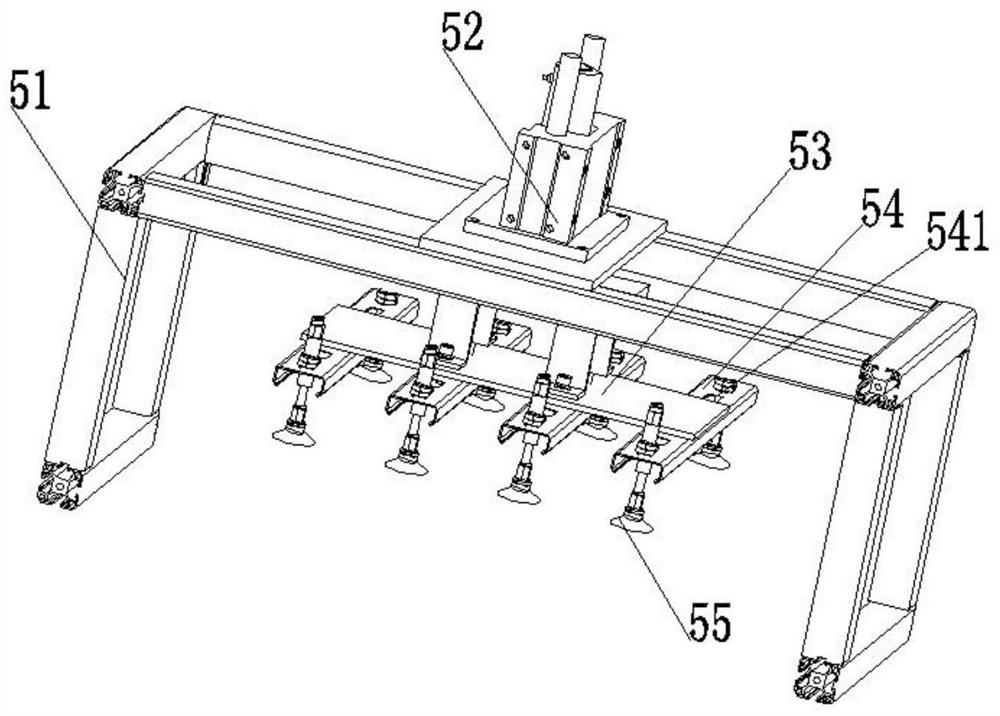

[0032] Such as figure 1 with Figure 4 As shown, the embodiment of the present invention provides a demoulding structure for rice cakes, including: a conveying mechanism 2, a mold 4 for conveying rice cakes, a knocking mechanism 3 erected above the conveying mechanism 2, and a knocking mechanism 3 for Knock the back of the mold 4 on the conveying mechanism 2; set up the adsorption mechanism 5 on the conveying mechanism 2 facing the conveying direction of the knocking mechanism 3, the adsorption mechanism 5 is used to adsorb the mold 4: the detection module 6 is used for Detect the position of the mold 4 on the conveying mechanism 2; the control module is used to control the knocking mechanism 3 to knock the mold 4 or control the adsorption mechanism 5 to absorb the back cover of the mold 4 according to the position of the mold 4 detected by the detection module 6 .

[0033] Wherein, the conveying mechanism 2 is erected on the supporting frame I1, and the supporting frame 1 is...

Embodiment 2

[0042] On the basis of Embodiment 1, the beating mechanism 3 and the adsorption mechanism 5 are all provided with a limit structure toward the side of the conveying direction. The limit structure is a cylinder, and the cylinder is electrically connected to the control module. When the cylinder is extended, it can block Die moves.

[0043] How this example works

[0044] When the travel switch receives the position information of the mold 4, the control module controls the elongation of the cylinder to stop the movement of the mold 4, and at the same time controls the conveying mechanism 2 to stop working, and then performs the striking and absorbing of the mold 4, the principle of striking and absorbing and The working principle of the above-mentioned embodiment 1 is the same.

Embodiment 3

[0046] On the basis of Example 1, such as Figure 7As shown, in order to prevent hitting the mold 4 from damaging the rollers of the conveying mechanism 2, the device also includes a material ejector mechanism 8, which is arranged at the bottom of the support frame I1 directly below the beating mechanism 3, and the material ejector mechanism 8 The rod 831 can pass between the rollers of the conveying mechanism 2 to jack up the mold 4 on the conveying mechanism 2 .

[0047] Wherein, the ejecting mechanism 8 comprises a support frame IV81, and the bottom of the support frame IV81 and the support frame I1 is fixed, and the support frame IV81 is provided with a telescopic mechanism III82 whose telescopic end is vertically upward, and the telescopic end of the telescopic mechanism III82 is connected with a support plate IV83, A plurality of vertical ejector rods 831 are provided on the side of the support plate IV83 facing away from the telescopic mechanism III82.

[0048] How thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com