Reinforcing steel bar butt welding machine capable of changing reinforcing steel bar forming angle

A technology of butt welding machine and steel bar, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding efficiency and long preprocessing time, and achieve the effect of improving welding efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

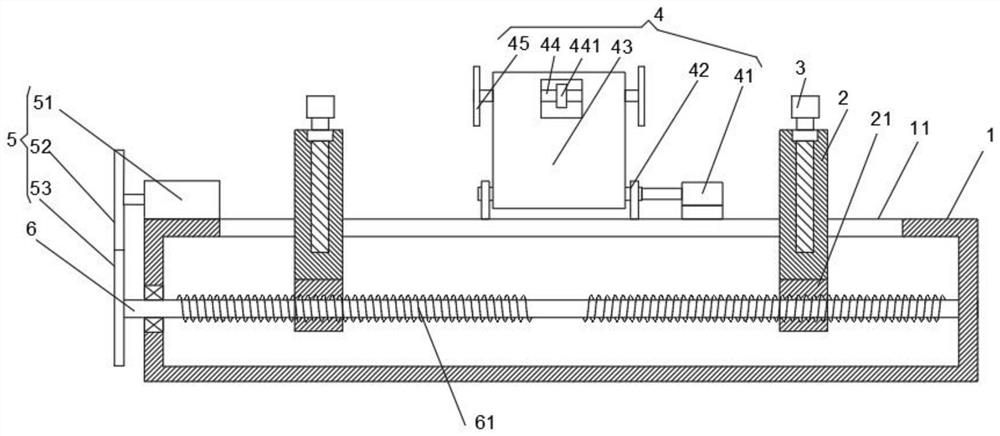

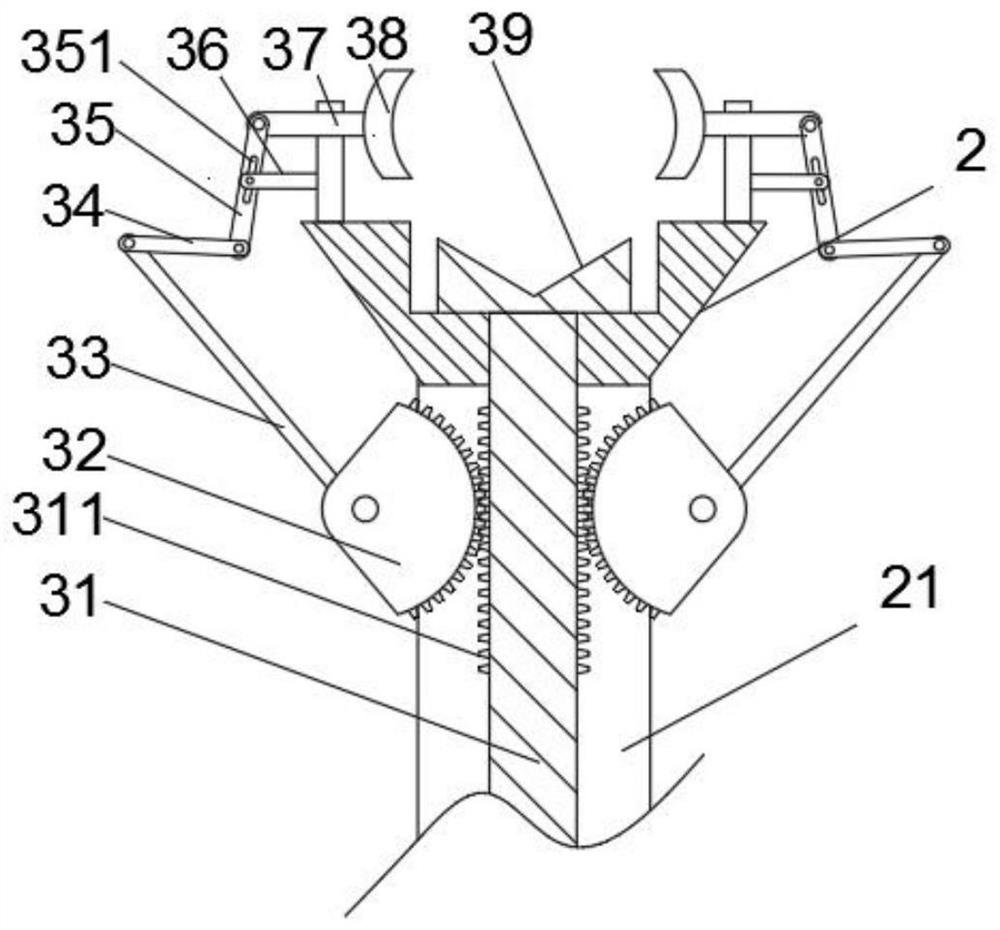

[0028] Attached below figure 1 And attached figure 2 , a specific embodiment of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0029] like figure 1 As shown, the embodiment of the present invention provides a steel bar butt welding machine capable of changing the forming angle of the steel bar, including: a box body 1, a slot 11 is opened on the top, and the slot 11 communicates with the inside of the box body 1; The rotating shaft I6 in the body 1 is provided with two sections of threaded sections 61 with opposite directions of rotation; the driving structure I5 and the two supporting structures 2 arranged on the box body 1 for driving the rotating shaft I6 are vertically penetrated In the slot 11, a slider 21 is arranged at the bottom thereof, and the slider 21 is correspondingly installed on the threaded section 61: the clamping structure 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com