Ceramic mobile phone shell and preparation method thereof

A mobile phone shell and ceramic technology, which is applied to ceramic molding machines, manufacturing tools, branch equipment, etc., can solve the problems of high processing cost, long production cycle, and reduced fracture toughness of ceramics, so as to meet the needs of large-scale production, improve production efficiency, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a ceramic mobile phone shell, comprising:

[0040] (1) Dissolve submicron ceramic powder, dispersant, binder and plasticizer in an organic solvent, and perform ball milling to form a uniform slurry;

[0041] The submicron ceramic powder contains at least one of zirconia and alumina, and the zirconia contains 1-8wt% yttrium oxide. The particle size of the submicron ceramic powder is 0.1-0.5 μm. Preferably, the zirconia contains 2-5wt% yttrium oxide. The particle size of the submicron ceramic powder is 0.2-0.4 μm. The particle size of the powder is set at 0.1-0.5 μm, which is set according to the tape casting process and the performance of the finished product after sintering. The particle size of the powder is too fine, and the solid content of the casting slurry is too low, resulting in easy deformation, cracking, and incomplete firing during sintering. If the particle size of the powder is too large, on the one hand, th...

Embodiment 1

[0071] (1) Slurry preparation: Dissolve 10kg of zirconia powder in a mixed solvent of 5kg of butanone and absolute ethanol, the mass ratio of butanone and absolute ethanol is 3:2, add 80g of BYK dispersant, and ball mill first 5h, then add 825g of binder and 536g of plasticizer, the binder is polyvinyl butyral, the plasticizer is dioctyl phthalate, and ball milled for 24h to form a uniform slurry.

[0072] (2) Tape casting: The slurry in step (1) was vacuum defoamed to a vacuum degree of 0.1 MPa for 15 hours, and tape cast to prepare a 0.2 mm cast film.

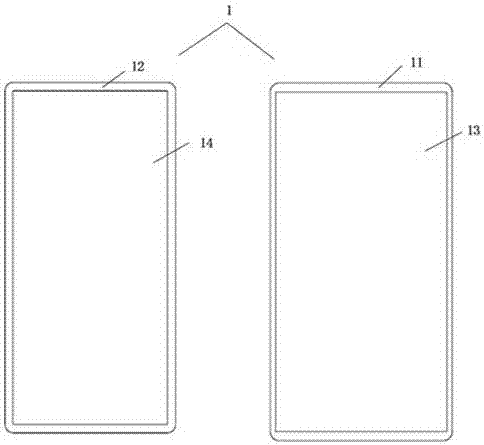

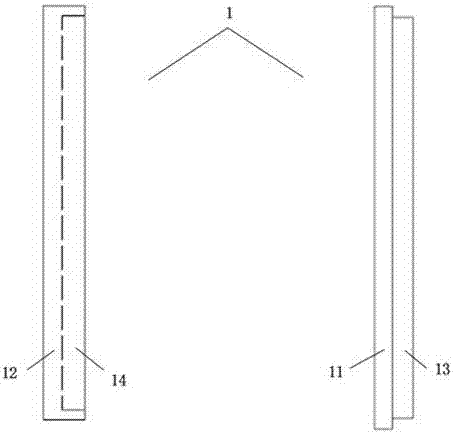

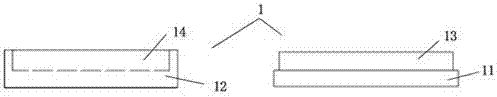

[0073] (3) Differential Laminations: Combining Figure 1 Divide the casting diaphragm in step (2) into diaphragms that match the size and shape of the die, including the differential diaphragm for the main body of the shell and the differential diaphragm for the frame of the shell;

[0074] Spray release agent on the mold;

[0075] Stacking the differential diaphragm of the shell frame on the boss of the first mold, and sup...

Embodiment 2

[0080] (1) Slurry preparation: Dissolve 10kg of zirconia powder in a mixed solvent of 5kg of xylene and absolute ethanol, the mass ratio of xylene and absolute ethanol is 4:1, add 80g of BYK dispersant, and ball mill first 5h, then add 825g of binder and 742g of plasticizer, the binder is polyvinyl butyral, the plasticizer is butyl benzyl phthalate, and ball milled for 24h to form a uniform slurry.

[0081] (2) Tape casting: The slurry in step (1) was vacuum defoamed to a vacuum degree of 0.1 MPa for 15 hours, and tape cast to prepare a 0.2 mm cast film.

[0082] (3) Differential Laminations: Combining Figure 1 Divide the casting diaphragm in step (2) into diaphragms that match the size and shape of the die, including the differential diaphragm for the main body of the shell and the differential diaphragm for the frame of the shell;

[0083] Spray silicone oil on the mold;

[0084] Stacking the differential diaphragm of the shell frame on the boss of the first mold, and sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com