A dental implant and a method for preparing a weak-base nanometer surface thereof

A dental implant, weak alkaline technology, used in dental prostheses, dentistry, dental implants, etc., can solve the problems of complex treatment process and poor targeting of osteogenic differentiation of cells, so as to promote bone healing and improve the adhesion of osteoblasts. rate, the effect of promoting binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

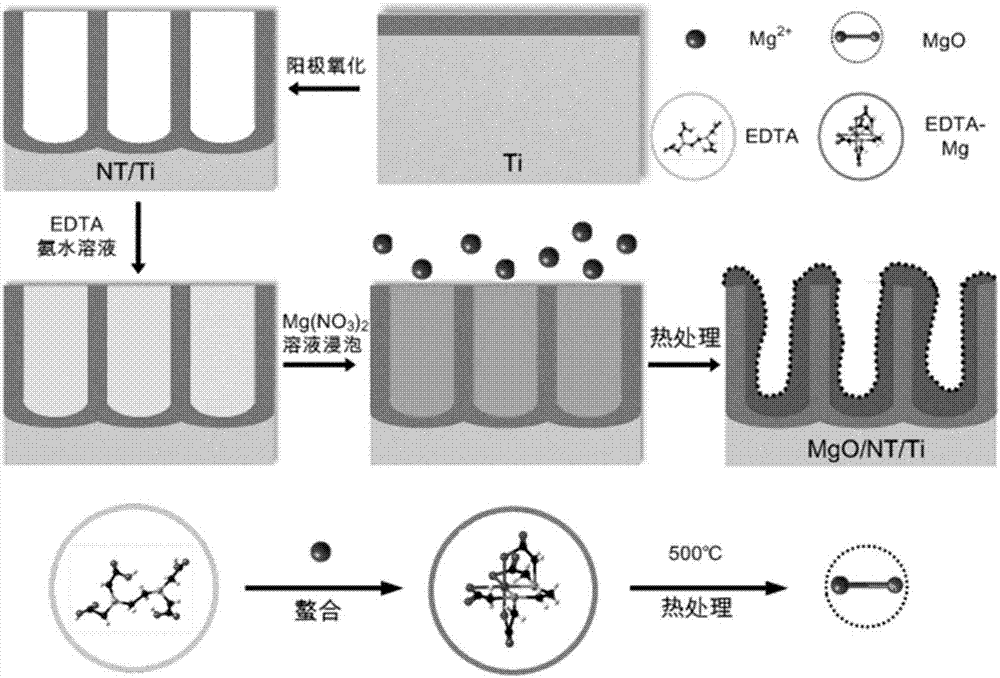

[0032] A dental implant, the surface of which is treated by:

[0033] (1) Select the medical pure titanium dental implant as the base body, and perform surface cleaning: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 15 minutes each, and then dry naturally;

[0034] (2) Configure the anodic oxidation electrolyte: the electrolyte used is an aqueous glycerol solution of ammonium fluoride, in which the mass fraction of ammonium fluoride is 0.5 wt%, and the volume fraction of water is 2 vol%;

[0035] (3) Preparation of uniform titanium dioxide nanotube film layer by anodic oxidation method: using constant voltage direct current anodic oxidation technology, the pure titanium dental implant after step (1) is used as the anode, and the graphite electrode or platinum sheet electrode is used as the cathode, and put into the step ( 2) In the prepared electrolyte; the working voltage is 20 V, the oxidation time is 3 hours, and the reaction temperature is roo...

Embodiment 2

[0045] A dental implant, the surface of which is treated by:

[0046] (1) Select the medical pure titanium dental implant as the base body, and perform surface cleaning: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 15 minutes each, and then dry naturally;

[0047] (2) Configure the anodic oxidation electrolyte: the electrolyte used is an aqueous glycerol solution of ammonium fluoride, in which the mass fraction of ammonium fluoride is 1.0 wt%, and the volume fraction of water is 25 vol%;

[0048] (3) Preparation of uniform titanium dioxide nanotube film layer by anodic oxidation method: using constant voltage direct current anodic oxidation technology, the pure titanium dental implant after step (1) is used as the anode, and the graphite electrode or platinum sheet electrode is used as the cathode, and put into the step ( 2) In the prepared electrolyte; the working voltage is 30 V, the oxidation time is 4 hours, and the reaction temperature is ro...

Embodiment 3

[0053] A dental implant, the surface of which is treated by:

[0054] (1) Select the medical pure titanium dental implant as the base body, and perform surface cleaning: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 15 minutes each, and then dry naturally;

[0055] (2) Configure the anodic oxidation electrolyte: the electrolyte used is an aqueous glycerol solution of ammonium fluoride, in which the mass fraction of ammonium fluoride is 0.5 wt%, and the volume fraction of water is 50 vol%;

[0056] (3) Preparation of uniform titanium dioxide nanotube film layer by anodic oxidation method: using constant voltage direct current anodic oxidation technology, the pure titanium dental implant after step (1) is used as the anode, and the graphite electrode or platinum sheet electrode is used as the cathode, and put into the step ( 2) In the prepared electrolyte; the working voltage is 40 V, the oxidation time is 3 hours, and the reaction temperature is ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com