A kind of preparation method of tungsten disulfide/super P sodium ion battery self-supporting negative electrode

A sodium-ion battery, tungsten disulfide technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of abnormal crystal growth of materials, difficult to control process conditions, difficult to control reaction ratio, etc., to improve the interface bonding , The effect of shortening the production process and promoting the insertion/extraction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of tungsten disulfide / Super P sodium ion battery self-supporting negative electrode, comprising the following steps:

[0031] 1) Take 1.5g of tungsten powder and grind it and dissolve it in 30mL of hydrogen peroxide solution with a mass fraction of 30%, keep the temperature at 25-40°C, and form a suspension A after 1h of reaction;

[0032] 2) Add analytically pure isopropanol to A, add 30-40ml of isopropanol to every 30ml of suspension A, stir with a magnetic stirrer at a speed of 500-700 rpm for 30-90min to form precursor B;

[0033] 3) Use a powder tablet press to press the ground Super P into an electrode support C with a thickness of 1mm, a length of 4mm, and a width of 2.5mm at a pressure of 20-30MPa;

[0034] 4) Put B into the hydrothermal induction kettle, then put C perpendicular to the magnetic field line of the induction coil in the hydrothermal induction heating equipment, and add 0.1-0.3g of C to every 60mL of B, seal the kettle, and pla...

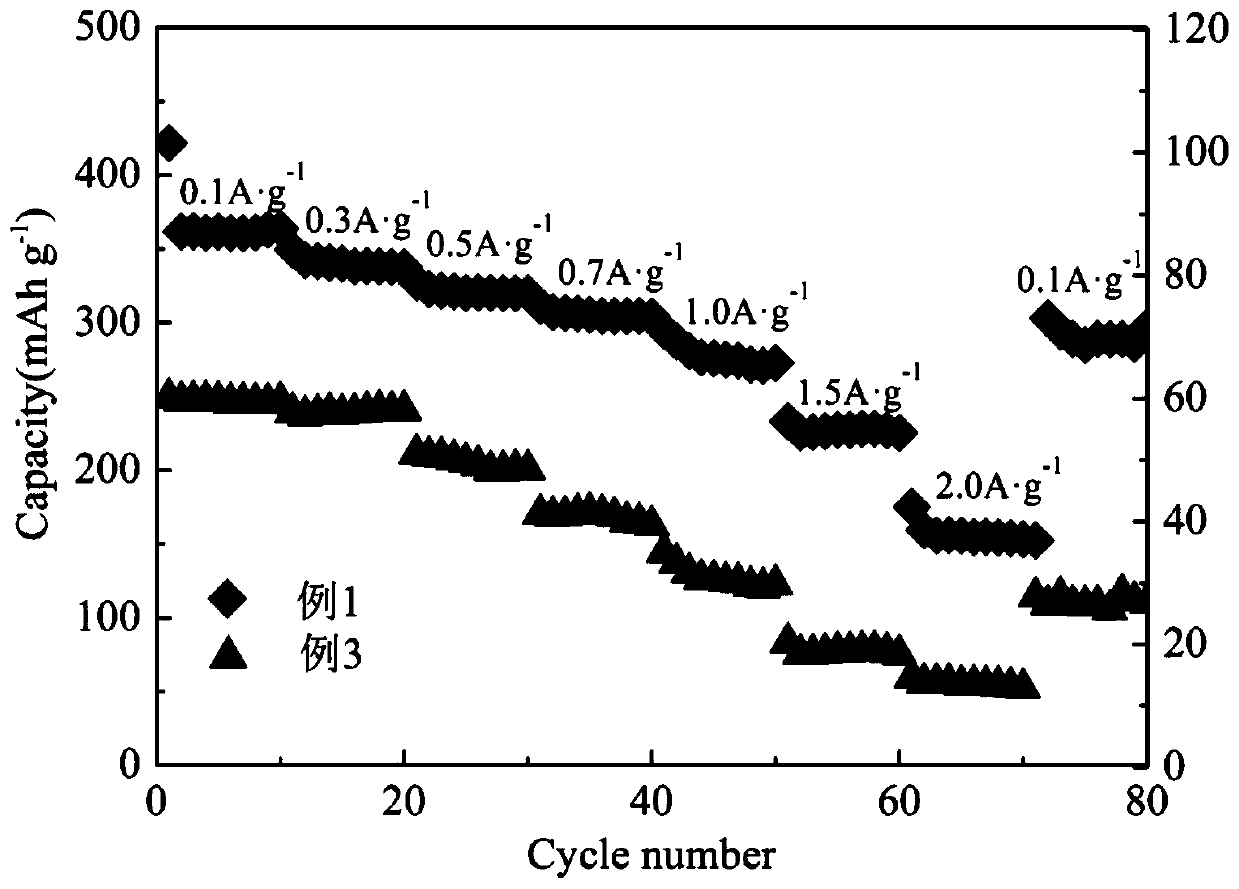

Embodiment 1

[0039] (1) Take 1.5g of tungsten powder and grind it and dissolve it in 30mL of hydrogen peroxide solution with a mass fraction of 30%, keep the temperature at 35°C, and form suspension A after 1h of reaction;

[0040] (2) Add 35 mL of analytically pure isopropanol to A, and stir with a magnetic stirrer at a speed of 600 rpm for 60 min to form precursor B;

[0041] (3) Use a powder tablet press to compress the ground Super P into an electrode support body C with a thickness of 1 mm, a length of 4 mm, and a width of 2.5 mm with a pressure of 25 MPa;

[0042] (4) Put 60ml of precursor B into the hydrothermal induction kettle, put 0.2g C perpendicular to the magnetic field line of the induction coil in the hydrothermal induction heating equipment, seal the kettle, and place it in the hydrothermal induction heating equipment , heated up from room temperature to 180°C with an induction frequency of 500KHz, and kept it warm for 5h to obtain WO 2 / Super P composite material D;

[004...

Embodiment 2

[0047] (1) Take 1.5g of tungsten powder and grind it and dissolve it in 30mL of hydrogen peroxide solution with a mass fraction of 30%, keep the temperature at 40°C, and form a suspension A after 1h of reaction;

[0048] (2) Add 30 mL of analytically pure isopropanol to A, and stir with a magnetic stirrer at a speed of 500 rpm for 90 min to form precursor B;

[0049] (3) Use a powder tablet press to compress the ground Super P into an electrode support body C with a thickness of 1 mm, a length of 4 mm, and a width of 2.5 mm with a pressure of 20 MPa;

[0050] (4) Put 60ml of precursor B into the hydrothermal induction kettle, then put 0.3g C perpendicular to the magnetic field line of the induction coil in the hydrothermal induction heating equipment, seal the kettle, and place it in the hydrothermal induction heating equipment In the process, the temperature was raised from room temperature to 200°C with an induction frequency of 600KHz, and kept for 4h to obtain WO 2 / Super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com