High-strength addition type liquid silicone rubber impregnating liquid and preparation and forming methods thereof

A liquid silicone rubber, addition molding technology, applied in the coating and other directions, can solve the problems of low mechanical strength of silicone rubber impregnated products, and the practical application value needs to be improved, achieve reasonable components and proportions, optimize mechanical properties and processing. Process, the effect of small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

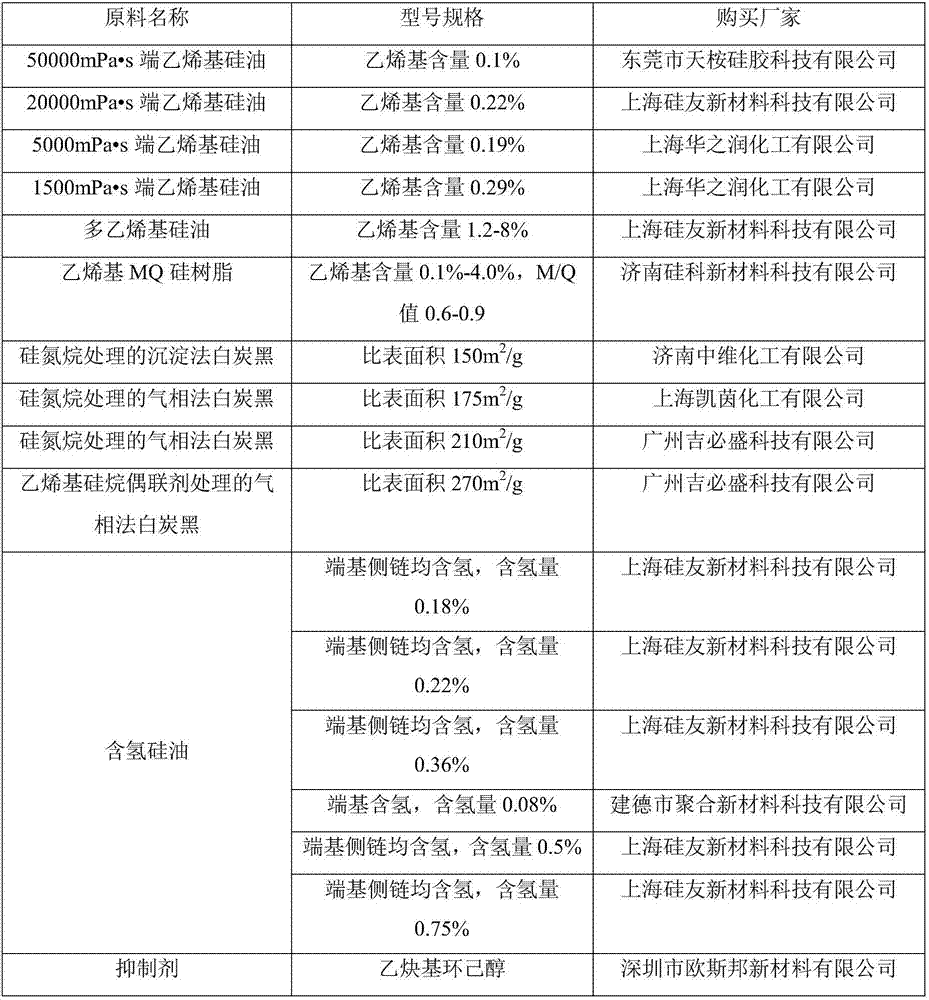

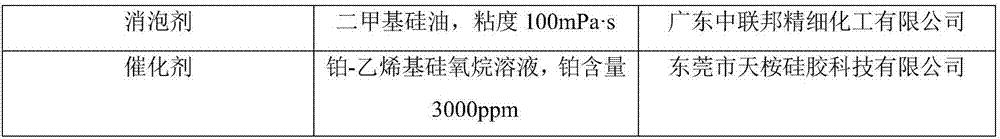

[0035] Step 1, 90 parts of 50000mPa·s terminal vinyl silicone oil, 10 parts of 20000mPa·s terminal vinyl silicone oil, 5 parts of polyvinyl silicone oil (vinyl content 4.7%), vinyl MQ silicone resin (vinyl content 0.9%) , M / Q=0.6) 20 parts, put into kneader, knead at room temperature for 1h;

[0036] Step 2. Raise the temperature to 80°C, continue kneading the kneaded product of step 1 for 1 hour, and add silazane in ten times during the kneading process to obtain a specific surface area of 175m 2 25 parts per gram of fumed silica; heat up to 120°C, knead for 4 hours; then cool to room temperature, slowly add 50 parts of 5000mPa·s terminal vinyl silicone oil, 30 parts of 1500mPa·s terminal vinyl silicone oil, and continue kneading 1.5h, finally evacuated and kneaded for 1h, and the kneaded final product was obtained after discharging;

[0037] Step 3. Put th...

Embodiment 2

[0041] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

[0042] Step 1, 70 parts of 50000mPa·s terminal vinyl silicone oil, 30 parts of 20000mPa·s terminal vinyl silicone oil, 5 parts of polyvinyl silicone oil (vinyl content 4.7%), vinyl MQ silicone resin (vinyl content 0.9%) , M / Q=0.6) 20 parts, put into kneader, knead at room temperature for 1h;

[0043] Step 2. Raise the temperature to 80°C, continue kneading the kneaded product of step 1 for 1 hour, and add silazane in ten times during the kneading process to obtain a specific surface area of 175m 2 25 parts per gram of fumed silica; then heat up to 120°C and knead for 4 hours; then cool to room temperature, add 50 parts of 5000mPa·s terminal vinyl silicone oil and 20 parts of 1500mPa·s terminal vinyl silicone oil slowly, and continue kneading 1.5h, finally evacuated and kneaded for 1h, and the kneaded final product was obtained after discharging;

[0044] Ste...

Embodiment 3

[0048] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

[0049] Step 1, 60 parts of 50000mPa·s terminal vinyl silicone oil, 40 parts of 20000mPa·s terminal vinyl silicone oil, 5 parts of polyvinyl silicone oil (vinyl content 4.7%), vinyl MQ silicone resin (vinyl content 0.9%) , M / Q=0.6) 20 parts, put into kneader, knead at room temperature for 1h;

[0050] Step 2. Raise the temperature to 80°C, continue kneading the kneaded product of step 1 for 1 hour, and add silazane in ten times during the kneading process to obtain a specific surface area of 175m 2 25 parts per gram of fumed silica; heat up to 130°C, knead for 4 hours; then cool to room temperature, add 50 parts of 5000mPa·s terminal vinyl silicone oil and 20 parts of 1500mPa·s terminal vinyl silicone oil slowly, and continue kneading 1.5h, finally evacuated and kneaded for 1h, and the kneaded final product was obtained after discharging;

[0051] Step 3. Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com