Toughened modified polylactic acid material and preparation method thereof

A polylactic acid material, toughening modification technology, applied in the field of polymer materials, can solve the problems that limit the wide application of PLA materials, slow crystallization rate, and decrease in material toughness, so as to improve dimensional stability and processing fluidity, and improve phase Capacitance, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

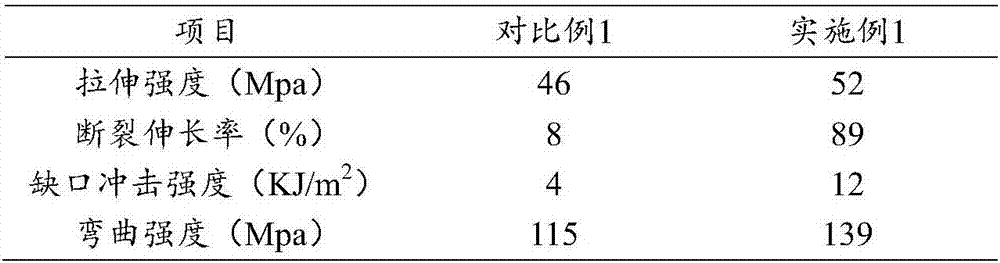

Examples

Embodiment 1

[0038] (1) Weigh 6g of LDHs and 35g of ε-CL into a three-neck flask, ultrasonicate for 30min, heat up to 110°C, add catalyst stannous octoate, N 2 React under protection for 24 hours. After the reaction is over, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 40°C. Dry for 24h to get LDHs-g-PCL.

[0039] (2) Add 2g of LDHs-g-PCL and 8g of polylactic acid into a three-necked flask equipped with a mechanical stirrer, feed nitrogen, raise the temperature of the oil bath to 195°C, and after the raw materials are completely melted, add 0.02g The hydrogenated diphenylmethane diisocyanate was added to the reaction system, reacted for 1 h in a nitrogen atmosphere, and finally removed the oil bath, and the reaction product was cooled to room temperature to crystallize to obtain a white product modified polylactic acid material.

[0040] (3) The modified polylactic aci...

Embodiment 2

[0042] (1) Weigh 6g of LDHs and 54g of ε-CL into a three-neck flask, ultrasonicate for 40min, heat up to 100°C, add catalyst stannous chloride, N 2 React under protection for 20 hours. After the reaction is over, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 35°C. Dry for 20h to obtain LDHs-g-PCL.

[0043] (2) Add 2g of LDHs-g-PCL and 10g of polylactic acid into a three-necked flask equipped with a mechanical stirrer, feed nitrogen, raise the temperature of the oil bath to 165°C, and after the raw materials are completely melted, add 0.01g Hydrogenated diphenylmethane diisocyanate and 0.012g hydrogenated toluene diisocyanate were added to the reaction system, reacted in a nitrogen atmosphere for 2 hours, and finally removed the oil bath, and the reaction product was cooled to room temperature to crystallize to obtain a white product modified polylactic acid ...

Embodiment 3

[0046] (1) Weigh 6g of LDHs and 34g of ε-CL into a three-neck flask, ultrasonicate for 35min, heat up to 140°C, add catalyst stannous oxide, N 2 React under protection for 30 hours. After the reaction is over, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 45°C. Dry for 20h to obtain LDHs-g-PCL.

[0047] (2) Add 3g of LDHs-g-PCL and 7g of polylactic acid into a three-necked flask equipped with a mechanical stirrer, blow in nitrogen, raise the temperature of the oil bath to 180°C, and after the raw materials are completely melted, press polylactic acid Add toluene diisocyanate to the reaction system at a molar ratio of 1:1, react in a nitrogen atmosphere for 1.5 hours, and finally remove the oil bath, and wait for the reaction product to cool to room temperature and crystallize to obtain a white product modified polylactic acid material.

[0048] (3) The modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com