Lithium ion energy storage device, and method and electrolytic tank apparatus for prefabricating lithium for negative electrode of lithium ion energy storage device

A technology of lithium ion and electrolytic cell, which is applied in the field of electrochemistry, can solve problems such as difficulty in metal lithium recovery and reuse, influence on the controllability of prefabricated lithium, and potential safety hazards, and achieve mature manufacturing processes, eliminate potential safety hazards, and avoid short circuits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

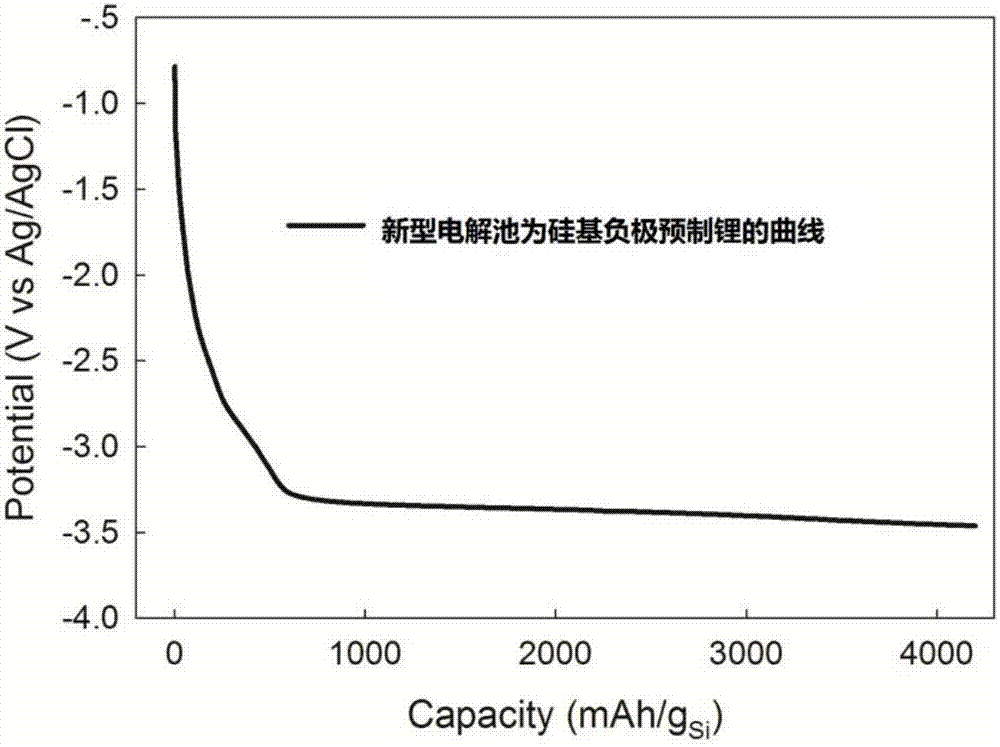

[0039] For prefabricating lithium for the silicon-based lithium battery negative electrode material, first the electrolytic cell device according to the present invention is figure 1 Assemble. First, the cathode of the electrolytic cell was assembled in an argon-filled glove box, and the gel electrolyte used was 1M LiPF with an infiltration volume ratio of 3:7. 6 PVDF / PMMA / PVDF in EC / DEC organic electrolyte is placed in a stainless steel nut and attached to a ceramic-based solid electrolyte film. The ceramic-based solid electrolyte film used is Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO 2 Glass-ceramic membrane. Paste the silicon-based negative electrode on the gel electrolyte, and tighten the stainless steel bolts. The electrolytic cell cathode is then assembled with the glass anode and sealed with a second rubber ring. Place the Ag / AgCl reference electrode and the titanium rod wound with copper wire on the glass anode, pour 0.5MLi into the glass anode 2 SO 4 aqu...

Embodiment 2

[0041] For prefabricating lithium for the negative electrode material of silicon-based lithium battery, the device is first figure 1 Assemble. First, the cathode of the electrolytic cell was assembled in an argon-filled glove box, and the gel electrolyte used was 1M LiPF impregnated in a volume ratio of 3:7. 6 PVDF / PMMA / PVDF in EC / DEC organic electrolyte is placed in a stainless steel nut and attached to a ceramic-based solid electrolyte film. The ceramic-based solid electrolyte film used is Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO 2 Glass-ceramic membrane. Paste the silicon-based negative electrode on the gel electrolyte, and tighten the stainless steel bolts. The electrolytic cell cathode is then assembled with the glass anode and sealed with a second rubber ring. Place the Ag / AgCl reference electrode and the titanium rod wound with copper wire on the glass anode, pour 0.5MLi into the glass anode 2 SO 4 aqueous solution, and through the argon, the device is as...

Embodiment 3

[0043] For prefabricating lithium for the negative electrode material of manganese oxide-based lithium battery, firstly, the device is figure 1 Assemble. First, the cathode of the electrolytic cell was assembled in an argon-filled glove box, and the gel electrolyte used was 1M LiPF soaked in a volume ratio of 3:7 6

[0044] The PVDF / PMMA / PVDF in the EC / DEC organic electrolyte is placed in a stainless steel nut and attached to a ceramic-based solid electrolyte film. The ceramic-based solid electrolyte film used is Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO 2 Glass-ceramic membrane. Paste the manganese oxide-based negative electrode on the gel electrolyte, and tighten the stainless steel bolts. The cathode of the electrolytic cell is then assembled with the glass anode and sealed with a rubber ring. Place the Ag / AgCl reference electrode and the titanium rod wound with copper wire on the glass anode, pour 0.5MLi into the glass anode 2 SO 4 aqueous solution, and thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com