A preparation process of high triso content inert base dispersed fuel pellets

A technology for dispersing fuel and preparation process, which is applied in nuclear engineering, manufacturing reactors, climate sustainability, etc. It can solve the problems of poor particle dispersion effect of TRISO, difficult to achieve industrialization, and high equipment requirements, so as to improve the holding performance and safety. performance and economy, the effect of reducing the volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

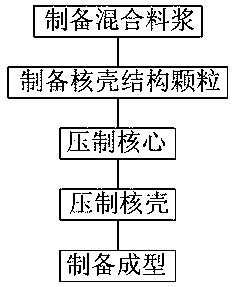

Method used

Image

Examples

Embodiment 2

[0031] (1) Preparation of mixed slurry: by weight percentage, 5% alumina powder, 3% yttrium oxide powder, 2% silica powder and 90% silicon carbide powder were wetted with propanol as a wet mixing solvent. Mixing, and then adding polyethyleneimine accounting for 3% of the total mass of sintering aid and silicon carbide powder as a dispersant, stirring for 4 hours to make it fully mixed, to obtain a uniformly dispersed silicon carbide mixed slurry;

[0032](2) Preparation of core-shell particles: put standard nuclear fuel spherical particles containing uranium dioxide (three-structure isotropic particles) and TRISO particles with a diameter of 0.8-1.0mm into a heatable drum, open the drum, and The heating temperature is controlled at 60°C, and the TRISO particles are rolled in the drum. After the temperature of the TRISO particles rises to 60°C, part of the mixed slurry obtained in step (1) is atomized by spray deposition and sprayed continuously on the TRISO particles On the su...

Embodiment 3

[0037] (1) Preparation of mixed slurry: by weight percentage, 7.5% of alumina powder, 4.5% of yttrium oxide powder, 3% of silicon dioxide powder and 85% of silicon carbide powder were mixed with absolute ethanol as a wet mixing solvent. Wet mixing, and then adding polyethyleneimine accounting for 0.5% of the total mass of sintering aid and silicon carbide powder as a dispersant, stirring for 16 hours to make it fully mixed, to obtain a uniformly dispersed silicon carbide mixed slurry;

[0038] (2) Preparation of core-shell particles: put standard nuclear fuel spherical particles containing uranium dioxide (three-structure isotropic particles) and TRISO particles with a diameter of 0.8-1.0mm into a heatable drum, open the drum, and Control the heating temperature at 90°C, and roll the TRISO particles in the drum. After the temperature of the TRISO particles rises to 90°C, use an air pressure spray device to atomize part of the mixed slurry obtained in step (1) and spray it on th...

Embodiment 4

[0043] (1) Preparation of mixed slurry: by weight percentage, 4% of alumina powder, 2.4% of yttrium oxide powder, 1.6% of silicon dioxide powder and 92% of silicon carbide powder were mixed with absolute ethanol as a wet mixing solvent. Wet mixing, and then adding polyethyleneimine accounting for 2% of the total mass of sintering aid and silicon carbide powder as a dispersant, stirring for 12 hours to make it fully mixed, to obtain a uniformly dispersed silicon carbide mixed slurry;

[0044] (2) Preparation of core-shell particles: put standard nuclear fuel spherical particles containing uranium dioxide (three-structure isotropic particles) and TRISO particles with a diameter of 0.8-1.0mm into a heatable drum, open the drum, and The heating temperature is controlled at 80°C, and the TRISO particles are rolled in the drum. After the temperature of the TRISO particles rises to 80°C, the part of the mixed slurry obtained in step (1) is atomized with an air pressure spray device an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com