Wear-resistant and corrosion-resistant double-layer plastic pipeline and molding method thereof

A technology of anti-corrosion and corrosion-resistant materials, which is applied in the direction of pipeline protection, pipeline damage/wear prevention, coating, etc., and can solve problems such as aging, pipeline corrosion, damage and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

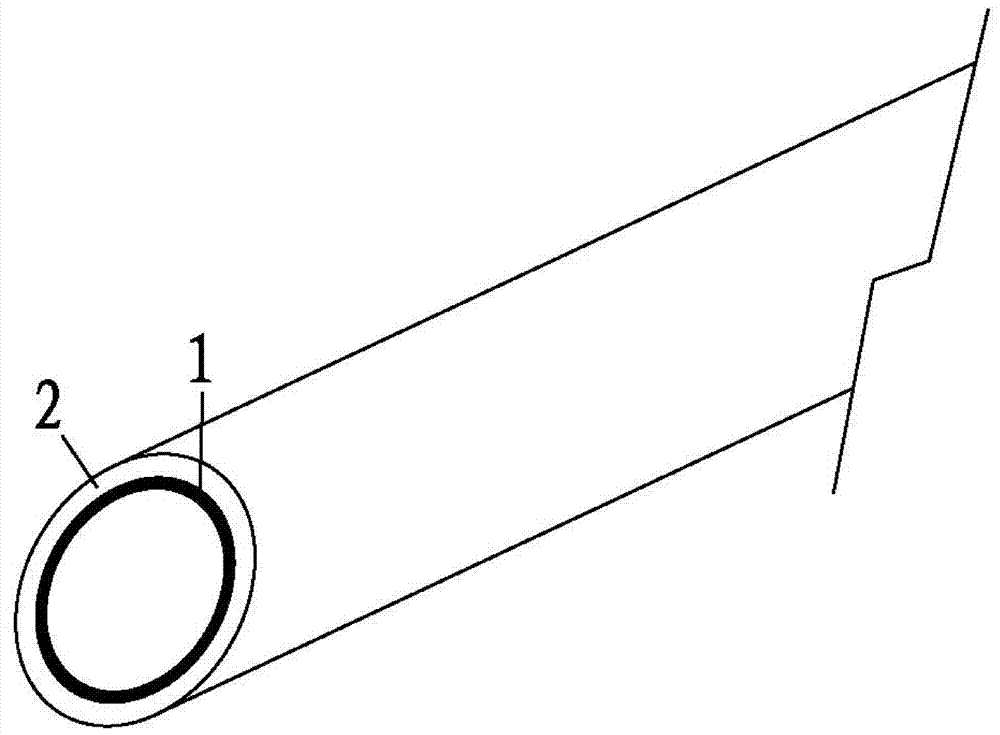

[0015] Such as figure 1 As shown, a wear-resistant and corrosion-resistant double-layer plastic pipe includes an inner layer 1 made of corrosion-resistant materials and an outer layer 2 made of wear-resistant materials. The inner layer 1 and the outer layer 2 are connected by injection molding. One piece, the inner layer 1 is a nylon layer, a polytetrafluoroethylene layer, a polypropylene layer, a polyether polyurethane layer or a PVC layer, and the outer layer 2 is a PU layer or a PE layer. Since the inner layer 1 is a nylon layer, a polytetrafluoroethylene layer, a polypropylene layer, a polyether polyurethane layer or a PVC layer, the pipe can transport acid-base gas or liquid; while the outer layer 2 is a PU layer or a PE layer , So that the outer layer 2 has high hardness, good flexibility, and strong wear resistance, and it is not easy to break during use.

[0016] When the inner layer 1 is a polyether polyurethane layer, it can make the inner and outer walls of the inner ...

Embodiment 2

[0020] A method for forming a wear-resistant and anti-corrosive double-layer plastic pipe according to Embodiment 1 includes the following steps:

[0021] Step 1. Prepare the mold for pipe molding and the corresponding inner layer 1 and outer layer 2 materials, then install the mold on the injection molding machine, and pour the inner layer 1 and outer layer 2 materials into the corresponding positions;

[0022] Step two, start the injection molding machine, the material of the inner layer 1 flows into the cavity of the mold to form the inner layer 1 structure after being melted, and then the material of the outer layer 2 flows into the cavity of the mold to form the outer layer structure after being melted. An integral structure covering the surface of the inner layer structure with the outer layer structure is obtained, and the integral structure is a double-layer plastic pipe.

[0023] It should be noted that: in the present invention, the two materials of the inner layer and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com