Method for preparing high-dispersion yttria-stabilized zirconia powder

A technology of yttrium-stabilized zirconia and high dispersion is applied in the field of preparation of yttrium-stabilized zirconia powder, which can solve the problems of unsolved hard agglomeration of ultrafine powder, poor powder dispersibility, low sintering activity, etc., so as to improve the agglomeration problem , good dispersibility, the effect of improving powder performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

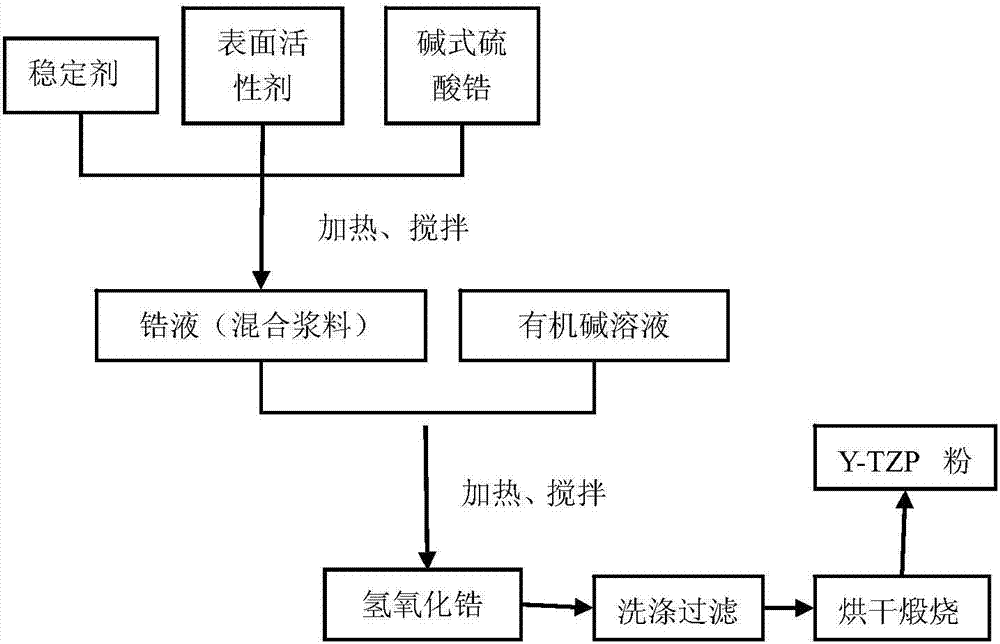

[0027] A preparation method of highly dispersed yttrium-stabilized zirconia powder, such as figure 1 shown, including the following steps:

[0028] Step 1, put Y 2 o 3 Dissolve in acid, heat and stir until completely dissolved, and prepare solution A; the acid is one of concentrated hydrochloric acid or concentrated nitric acid; acid and Y 2 o 3 The molar ratio is greater than 6:1; the heating temperature is 40-50°C.

[0029] Step 2, solution A and tensio-active agent that step 1 obtains are added to ZrOSO 4 ·nH 2 O slurry, heat and stir evenly to form a mixed solution B; the surfactant is polyethylene glycol (PEG400), cetyltrimethylammonium bromide (CTAB), polyacrylic acid (PAA) or dodecyl One of sodium alkylbenzenesulfonate (SDBS); ZrOSO 4 ·nH 2 O slurry concentration is 0.1~3mol / L; Y 2 o 3 Molar content of ZrOSO 4 ·nH 2 1% to 10% of the molar content of O; the mass of the surfactant is ZrOSO 4 ·nH 2 O 0.1‰~10‰ of slurry volume; heating temperature is 50~120℃. ...

Embodiment 1

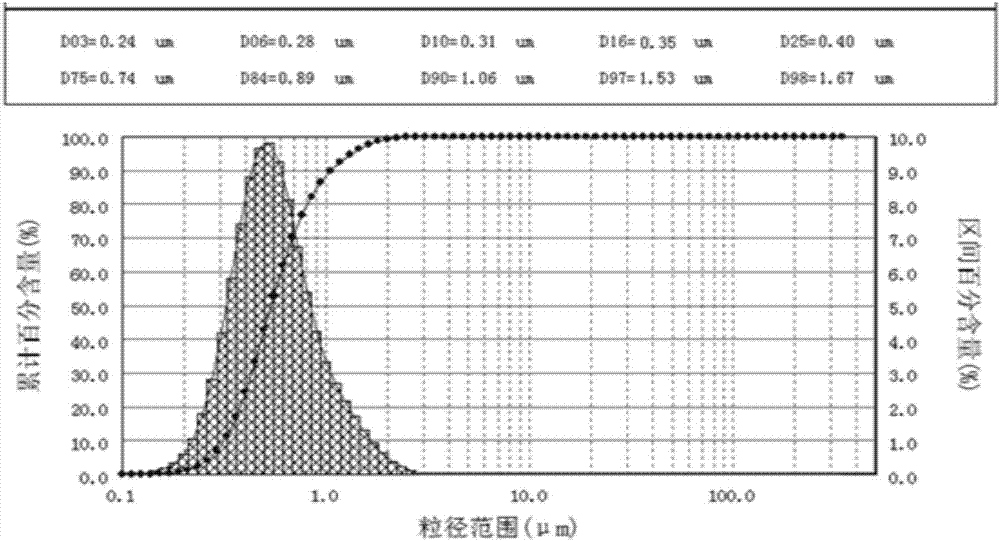

[0033] Weigh 6.984g Y 2 o 3 (0.031mol), dissolved in 30ml of concentrated hydrochloric acid, heated and stirred until completely dissolved. Add the above solution and 1ml PEG400 into 1000ml basic zirconium sulfate slurry with a concentration of 1mol / L, stir and heat to 70-75°C. Slowly add the guanidine aqueous solution dropwise to the mixed solution to make the pH = 8-10, and keep stirring while adding dropwise. After the dropwise addition, the stirring was continued for 2 h, and then the reaction was stopped to obtain a white zirconium hydroxide suspension. The precipitate was alternately centrifuged and washed with deionized water and absolute ethanol, and then dried at 80°C. The dried precipitate was calcined at 1100°C for 3 hours to obtain yttrium-stabilized tetragonal zirconia powder. The obtained zirconia powder is pressed into tablets and sintered at 1460°C, and the density reaches 6.05g / cm 3 , Vickers hardness up to 1290N / mm 2 .

Embodiment 2

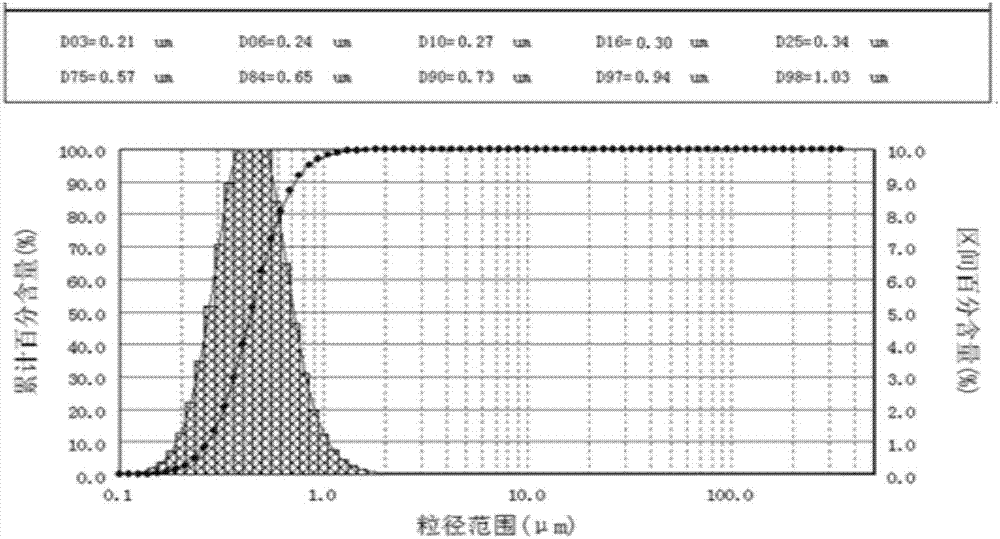

[0035] Weigh 6.984g Y 2 o 3 (0.031mol), dissolved in 30ml of concentrated hydrochloric acid, heated and stirred until completely dissolved. Add the above solution and 0.5g CTAB into 1000ml basic zirconium sulfate slurry with a concentration of 1mol / L, stir and heat to 70-75°C. Slowly add tetramethylammonium hydroxide aqueous solution dropwise to the mixed solution to make the pH = 8-10, and keep stirring while adding dropwise. After the dropwise addition, the stirring was continued for 2 h, and then the reaction was stopped to obtain a white zirconium hydroxide suspension. The precipitate was alternately centrifuged and washed with deionized water and absolute ethanol, and then dried at 80°C. The dried precipitate was calcined at 1100°C for 3 hours to obtain yttrium-stabilized tetragonal zirconia powder. The obtained zirconia powder is pressed into tablets and sintered at 1460°C, and the density reaches 6.08g / cm 3 , Vickers hardness up to 1300N / mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com