Hierarchical structure microsphere and preparation method and application thereof

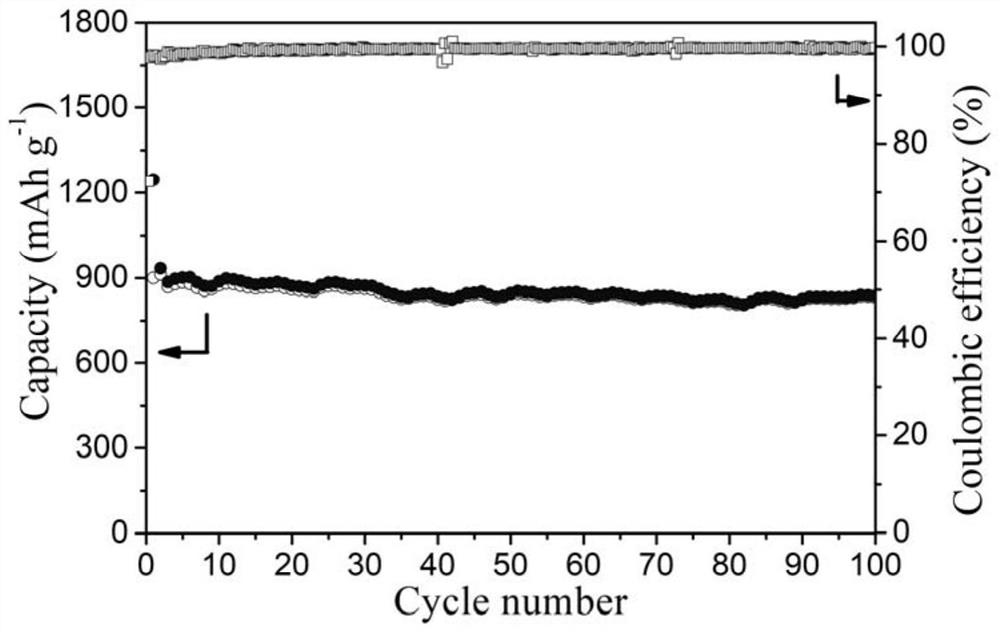

A hierarchical structure, micro-sphere technology, applied in structural parts, nanotechnology, nanotechnology, etc., can solve the problems of low cycle stability, low coulombic efficiency, low conductivity, particle agglomeration, etc., to improve electrical conductivity and lithium ion diffusion. efficiency, improved reversibility, and the effect of inhibiting particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

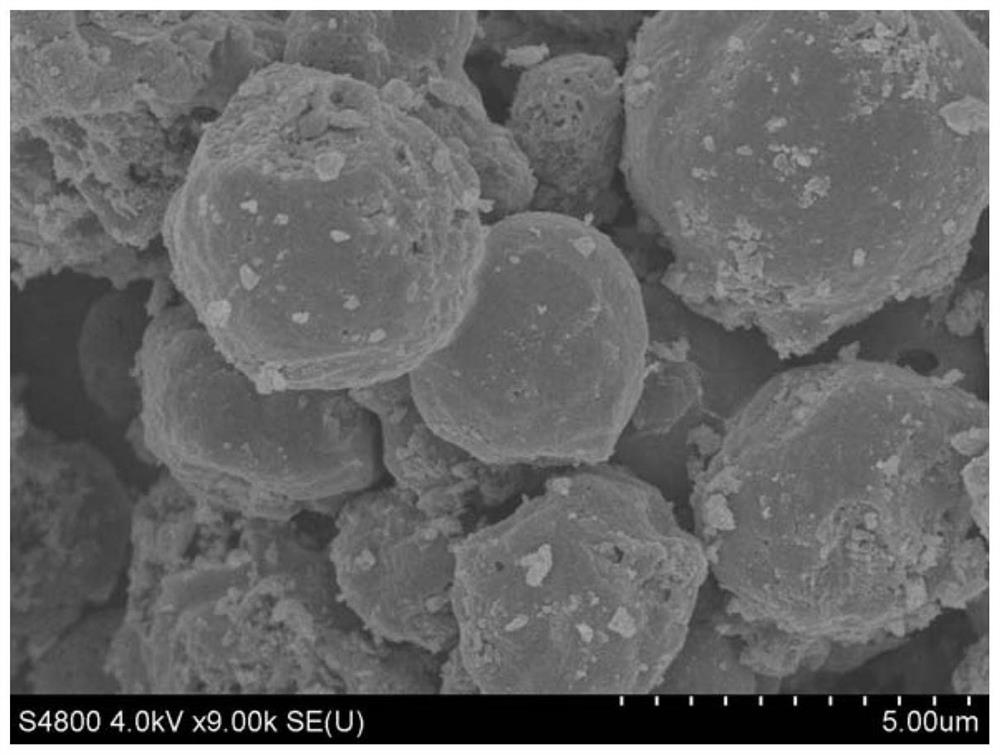

[0035] A kind of preparation of carbon-coated tin oxide and titania particles graded microspheres, the specific method is as follows:

[0036] The first step, 2.54g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0) was dissolved in 200ml of deionized water under stirring; in the second step, 10ml of ammonia (NH 3 ·H 2 O, 28%) was added dropwise to the above solution, stirred for 10 min to completely dissolve the resulting precipitate; in the third step, 1.3 g of sodium borohydride (NaBH 4 ) powder was added to the above solution, vigorously stirred for 30min until the colorless solution became a brown-black suspension; the fourth step, 1.6ml of tetrabutyl titanate was dispersed in 10ml of absolute ethanol, then, the above suspension was added dropwise In the liquid, stir for 10min; the fifth step, add 0.6g polyvinylpyrrolidone (molecular weight is 360,000) to the above-mentioned suspension, stir for 20min; the sixth step, carry out spray drying and granulation to the suspensi...

Embodiment 2

[0039] The preparation of a carbon-coated tin oxide and titania particle graded microspheres is similar to the steps in Example 1, using sucrose instead of polyvinylpyrrolidone as the carbon precursor, and the specific method is as follows:

[0040] The first step, 2.54g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0) was dissolved in 200ml of deionized water under stirring; in the second step, 10ml of ammonia (NH 3 ·H 2 O, 28%) was added dropwise to the above solution, stirred for 10 min to completely dissolve the resulting precipitate; in the third step, 1.3 g of sodium borohydride (NaBH 4) powder was added to the above solution, vigorously stirred for 30min to obtain a brown-black suspension; the fourth step, 1.6ml of tetrabutyl titanate was dispersed in 10ml of absolute ethanol, then, added dropwise to the above suspension, stirred for 10min The 5th step, joins 0.93g sucrose in the above-mentioned suspension, stirs 20min; The 6th step, carries out spray drying granulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com