A kind of preparation method of flaky strontium barium titanate powder material

A technology of barium strontium titanate and powder materials, which is applied in the field of preparation of flaky barium strontium titanate powder, which can solve the problems of cumbersome preparation process, easy agglomeration of powder, and high requirements for preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

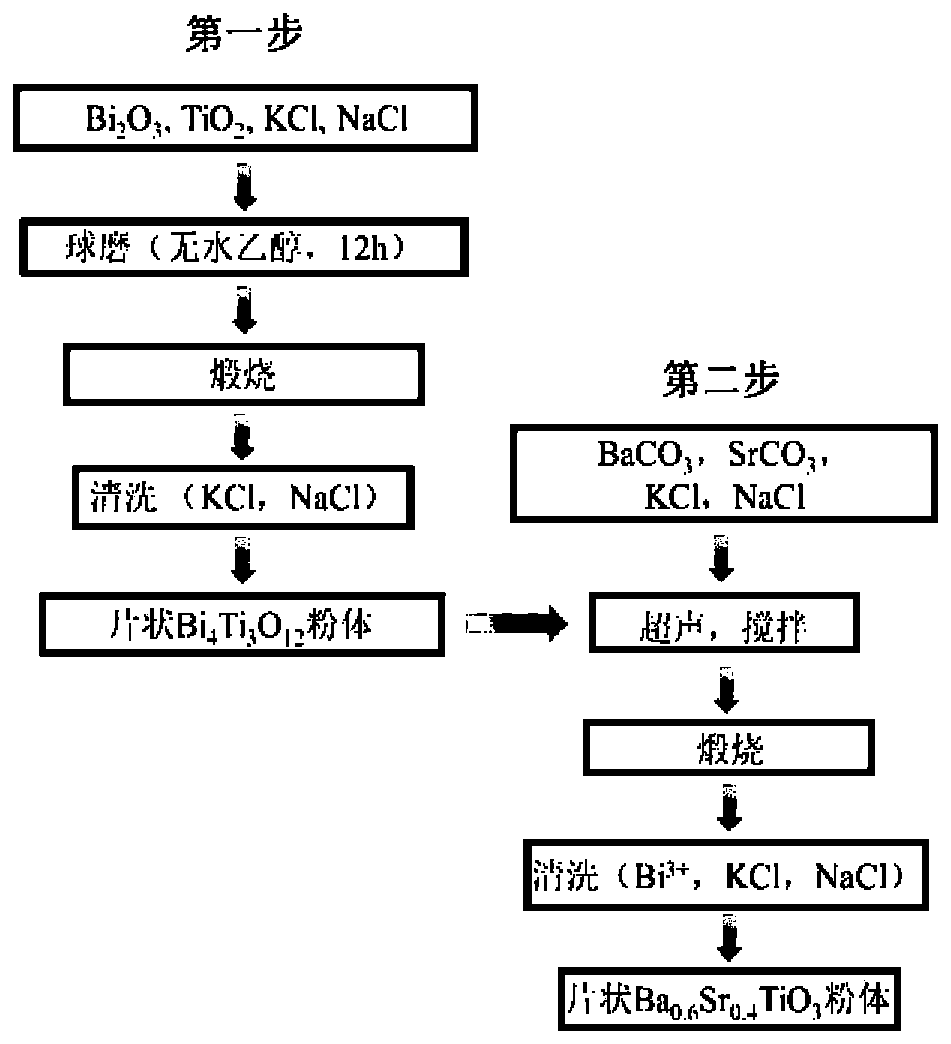

[0028] A kind of preparation method of flaky strontium barium titanate, with atomic composition as Ba 0.6 Sr 0.4 TiO 3 The strontium barium titanate is taken as an example. The two-step molten salt method is used to first prepare the flake bismuth titanate precursor, and then use the analytically pure barium carbonate and strontium carbonate powder and the bismuth titanate precursor as reactants, according to Ba 0.6 Sr 0.4 TiO 3 Molar ratio ingredients, using the liquid environment provided by molten salt melting to carry out topological chemical crystallite transformation reactions, and finally synthesize flaky Ba 0.6 Sr 0.4 TiO 3 Powder. The specific implementation steps are as follows:

[0029] Step 1: Prepare the mixture of bismuth titanate precursor. Weigh and analyze pure bismuth trioxide, titanium dioxide, sodium chloride and potassium chloride powder, wherein the mol ratio of bismuth trioxide and titanium dioxide is 2:3, and the mass ratio of sodium chloride an...

Embodiment 2

[0042] A kind of preparation method of flaky strontium barium titanate, with atomic composition as Ba 0.6 Sr 0.4 TiO 3 The strontium barium titanate is taken as an example. The two-step molten salt method is used to first prepare the flake bismuth titanate precursor, and then use the analytically pure barium carbonate and strontium carbonate powder and the bismuth titanate precursor as reactants, according to Ba 0.6 Sr 0.4 TiO 3 Molar ratio ingredients, using the liquid environment provided by molten salt melting to carry out topological chemical crystallite transformation reactions, and finally synthesize flaky Ba 0.6 Sr 0.4 TiO 3 Powder. The specific implementation steps are as follows:

[0043] Step 1: Prepare the mixture of bismuth titanate precursor. Weigh and analyze pure bismuth trioxide, titanium dioxide, sodium chloride and potassium chloride powder, wherein the mol ratio of bismuth trioxide and titanium dioxide is 2.1:3, and the mass ratio of sodium chloride ...

Embodiment 3

[0053] A kind of preparation method of flaky strontium barium titanate, with atomic composition as Ba 0.6 Sr 0.4 TiO 3 The strontium barium titanate is taken as an example. The two-step molten salt method is used to first prepare the flake bismuth titanate precursor, and then use the analytically pure barium carbonate and strontium carbonate powder and the bismuth titanate precursor as reactants, according to Ba 0.6 Sr 0.4 TiO 3 Molar ratio ingredients, using the liquid environment provided by molten salt melting to carry out topological chemical crystallite transformation reactions, and finally synthesize flaky Ba 0.6 Sr 0.4 TiO 3 Powder. The specific implementation steps are as follows:

[0054] Step 1: Prepare the mixture of bismuth titanate precursor. Weigh and analyze pure bismuth trioxide, titanium dioxide, sodium chloride and potassium chloride powder, wherein the mol ratio of bismuth trioxide and titanium dioxide is 2.2:3, and the mass ratio of sodium chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com