Self-dressing ultra-hard micro grinding tool pellet containing soluble resin material and preparation method thereof

A kind of abrasive pellets, soluble technology, applied in the direction of metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of high cost, complicated operation, etc., to promote dressing, promote dissolution, simple production method and use method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The implementation plan is as follows:

[0039] Step 1, first take diamond and silicon carbide abrasives with an average particle size of 2.5 microns, add fillers (copper-coated graphite, calcium oxide, cerium oxide, zinc oxide, cryolite powder, talcum powder, copper powder), wetting agent phenolic resin liquid, Mix for 30min to obtain mixed powder;

[0040] Step 2, put "insoluble" resin binder (phenolic resin), "soluble" resin binder (acrylic resin No. 4 - methacrylate and dimethylaminoethyl ester copolymer) into the V-type tank mix Mix evenly in the machine to obtain a mixed resin, in which the solubility of acrylic resin No. Ⅳ decreases with the increase of pH, generally dissolves at pH 1.2-5.0, and swells at pH 5-8;

[0041] Step 3, put the mixed powder and the mixed resin into the V-type tank mixer for mixing, and add the curing agent hexamethylenetetramine to obtain the pre-pressed powder;

[0042] Step 4, sieve the pre-compressed powder obtained in step 3, the ...

Embodiment 2

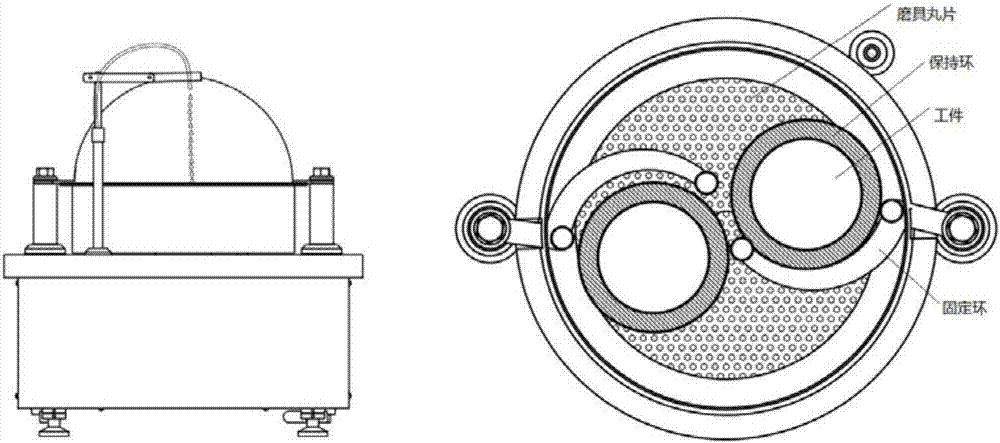

[0047] Embodiment 1 is obtained abrasive tool pellet and is processed on plane polishing machine, as figure 2 As shown, water-based abrasive fluid is continuously injected into the surface layer of the abrasive tool during the processing process to dissolve the acrylic resin No. Strong structural strength, so that the passivated diamond abrasive grains are easily separated from the surface of the abrasive tool under the action of the grinding force, and play the role of dressing the abrasive tool to expose new abrasive grains.

[0048] Acetic acid is used as a pH regulator. When the passivation of the abrasive tool is serious and the grinding efficiency decreases, the amount of acetic acid is increased in the grinding liquid, and the pH value is adjusted to 4-6, which will strengthen the "soluble" resin binder (acrylic resin No. Ⅳ ), the abrasive wears quickly, and the sharp abrasive grains on the sub-surface are exposed, and the abrasive pellets become sharp again, and onlin...

Embodiment 3

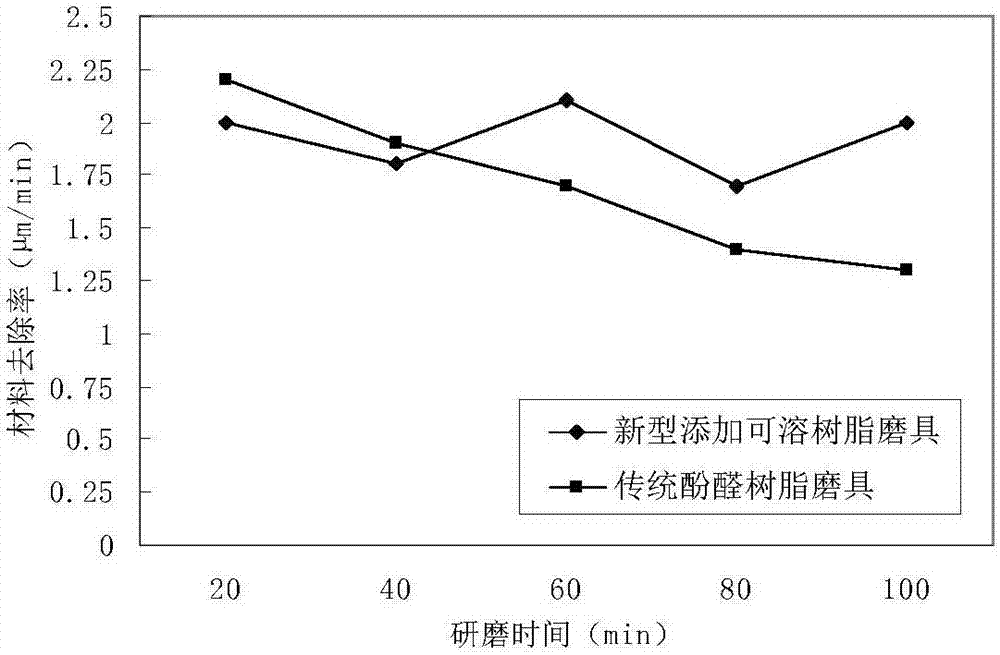

[0051] The grinding tool pellets obtained in embodiment 1 are ground in grinding liquids of different pH values, acetic acid is used as the acid pH regulator, sodium carbonate is used as the alkali pH regulator, and other grinding parameters are consistent, and the wear rate of the observed grinding tool is as follows: Figure 4 shown. It can be seen from the figure that as the PH value increases, from acidic to alkaline, the wear rate of the abrasive tool is also reduced. Therefore, considering the life of the abrasive tool, it is necessary to passivate the abrasive tool Degree, adjust the PH value, while sharpening the abrasive, control the wear of the abrasive. The "soluble" resin in the abrasive pellets obtained in Example 1 is an acid-soluble resin. When the material removal rate is high, the pH value of the grinding liquid can be controlled above 7 to slow down the wear of the abrasive. When the material removal rate drops, an acid PH regulator can be added to keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com