Preparation method of macroporous silica microsphere based on template method and applications thereof

A technology of macroporous silica gel and template method, which is applied in the field of macroporous silica gel microspheres and spherical silica gel particles, which can solve problems such as poor uniformity and insufficient pore size of silica gel microspheres, and achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

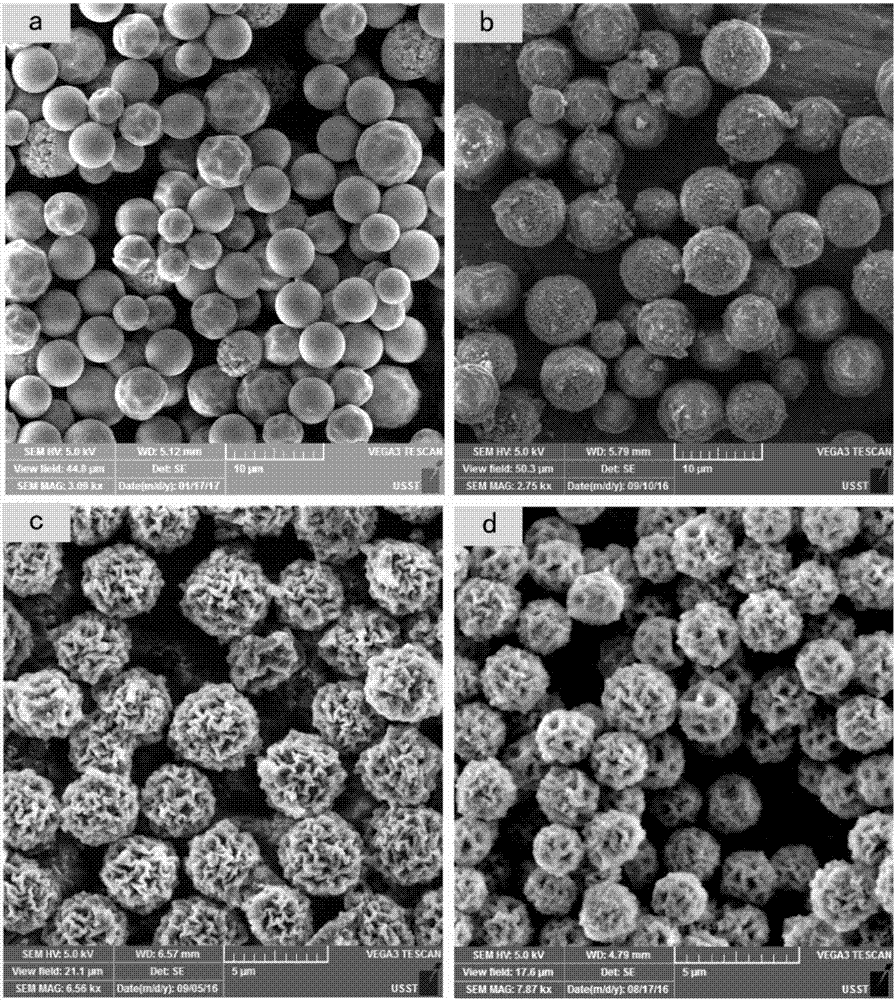

[0027] Embodiment 1 Preparation of macroporous silica microspheres

[0028] In a 500 ml Erlenmeyer flask, add 15 g of a commercially available cation exchange polymer microsphere (Zhengzhou Inno Biotechnology Co., Ltd. WCX), 25 ml of 50% TMSPTMA methanol solution, 25 ml of triethanolamine, 200 ml of deionized water and 125 ml ethanol, sonicated for 1 h; then placed in a constant temperature water bath at 30°C for 10 min with magnetic stirring, and then, under stirring, added a mixed solution of 25 ml TEOS and 75 ml ethanol drop by drop with a dropping funnel to control the rate of addition. The dropwise addition was completed within 30 min; continue to stir for 24 h; after the reaction was completed, take out the triangular flask and let it stand until the particles naturally settled, filter to remove the clear liquid, and wash the solid particles with ethanol centrifugation three times, dry them at 80°C for 12 h, and place them in the air Calcined at 600 °C for 10 h in the at...

Embodiment 2

[0029] Example 2 Surface bonding

[0030] Take 2 g of the obtained SiO 2The microspheres were soaked and stirred in 1 mol / L hydrochloric acid for 2 h, and the hydrochloric acid was washed away by centrifugation with water and ethanol, respectively, and dried at 80 °C; the acidified and dried SiO 2 Add 1.5 g of microspheres to a 250 ml three-neck round bottom flask after grinding, add 100 ml of dry toluene, stir magnetically in an oil bath, raise the temperature to 120°C to reflux the toluene for 10 min to remove water, then add 0.6 g of imidazole, After stirring for 10 min, add a mixed solution of 1.3 g octadecyldimethylsilyl chloride and 50 ml toluene with a dropping funnel within 15 min, and continue to reflux and stir the suspension for 8 h. Cool to room temperature, and after settling, remove the clear liquid by filtration, add 150 ml of fresh toluene to wash the solid particles, and then use methanol, methanol / water mixture and ethanol to wash by centrifugation, respecti...

Embodiment 3

[0031] Embodiment 3 packing and testing

[0032] Prepare 200ml of a mixture of isopropanol and chloroform with a volume ratio of 1:1, as a homogenate for later use; take 1.2 g of the above-mentioned bonded silica gel, add an appropriate amount of homogenate, ultrasonicate for 3 minutes, and then load it under a hydraulic pressure of 5000psi into a 4.6 × 50mm chromatographic column, and the protein separation test.

[0033] Standard protein chromatographic separation conditions: mobile phase A: 90% water, 10% acetonitrile, 0.1% trifluoroacetic acid; B phase: 90% acetonitrile, 10% water, 0.1% trifluoroacetic acid; flow rate: 0.8 ml / min; Detection wavelength 220 nm; Gradient elution program: 0→15.0min, 5%→65%B; 15→30min, keep 65%B. The test chromatogram is as figure 2 shown.

[0034] The invention prepares macroporous silica gel microspheres of about 2 micrometers, which can be used for the separation of proteins by high-performance liquid chromatography. figure 2 are the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap