A method and device for strengthening leaching of gold by controlling electric potential

A technology of enhanced leaching and potential, applied in the direction of improving process efficiency, etc., can solve the problems of long leaching cycle, unfavorable manual operation, and long time consumption, and achieve the effects of reducing material consumption, improving gold leaching efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

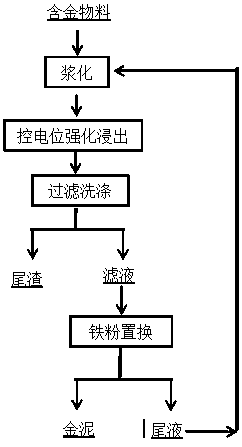

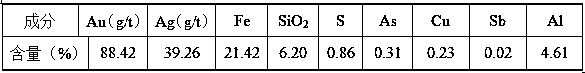

[0052] The refractory gold ore of a gold smelter was taken as the leaching raw material, and the chemical composition of the refractory gold ore is shown in Table 1.

[0053] Table 1 Contents of main elements in refractory gold ores

[0054]

[0055] The main phase of the extracted minerals is gangue (SiO 2 ) and arsenopyrite (FeAsS), and doped with a small amount of hematite (Fe 2 0 3 ), after the grinding operation, the arsenic-containing sulfur minerals wrapped in gold were oxidized and destroyed, 96.05% of the gold in the arsenopyrite was exposed, 80.52% of the gold in pyrite and other sulfides were exposed, iron oxide minerals and silicic acid Salt also has 57.05% and 16.54% wrapped gold exposed, and the gold in the ore is enriched.

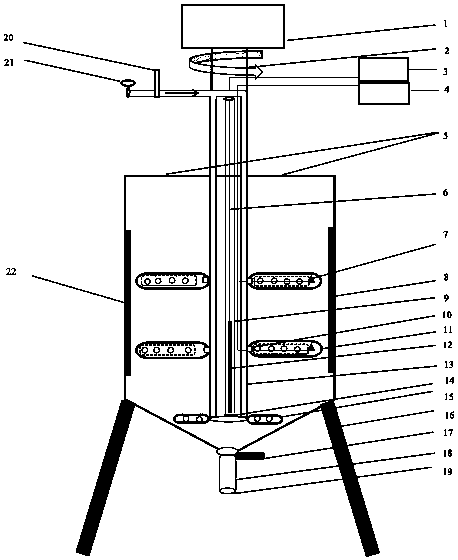

[0056] 1. Add the refractory gold ore and water into the potentiometric enhanced leaching device according to the ratio of material to liquid 1kg:2L, turn on the frequency conversion controller for stirring speed, control the stirring ...

Embodiment 2

[0069] Take a gold smelter's disposable gold ore as the leaching raw material, and the chemical composition of the disposable gold ore is shown in Table 2.

[0070] Table 2 Contents of main elements in roasted products of easy-to-handle gold mines

[0071]

[0072] After the ore is ground, the arsenic-containing sulfur minerals wrapped in gold are oxidized and destroyed, the gold in iron oxide minerals and silicate is fully exposed, and the gold in the ore is enriched.

[0073]1. Add the easy-to-handle gold ore and water into the material in the controlled potential enhanced leaching device according to the ratio of material to liquid 1kg:2L, turn on the stirring speed conversion controller, control the stirring shaft speed to 700r / min, adjust the intake valve, and control The air intake flowmeter shows that the ventilation pressure is 0.38MPa, the gas is evenly discharged through the air outlet holes of the ventilation pipes on each stirring blade, a large amount of bubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com