A kind of blue to green color tunable silicate phosphor and preparation method thereof

A fluorescent powder and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of low synthesis temperature, simple preparation method, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh sodium carbonate (Na 2 CO 3 ) 0.1590g, barium carbonate (BaCO 3 ) 1.7760g, silicon dioxide (SiO 2 ) 1.0802g, lanthanum oxide (La 2 o 3 ) 1.3825g, cerium oxide (CeO 2 )0.0108g, terbium oxide (Tb 4 o 7 ) 0.0841g, fully ground in an agate mortar and mixed evenly, pre-fired at 500°C for 12 hours in an air atmosphere, cooled to room temperature naturally, took out the sample and ground it, then sintered at 950°C for 12 hours in an air atmosphere, and cooled naturally To room temperature, the sample is taken out and ground to obtain the final product, and the obtained phosphor material is composed of: NaBa 3 La 2.829 Ce 0.021 Tb 0.15 Si 6 o 20 .

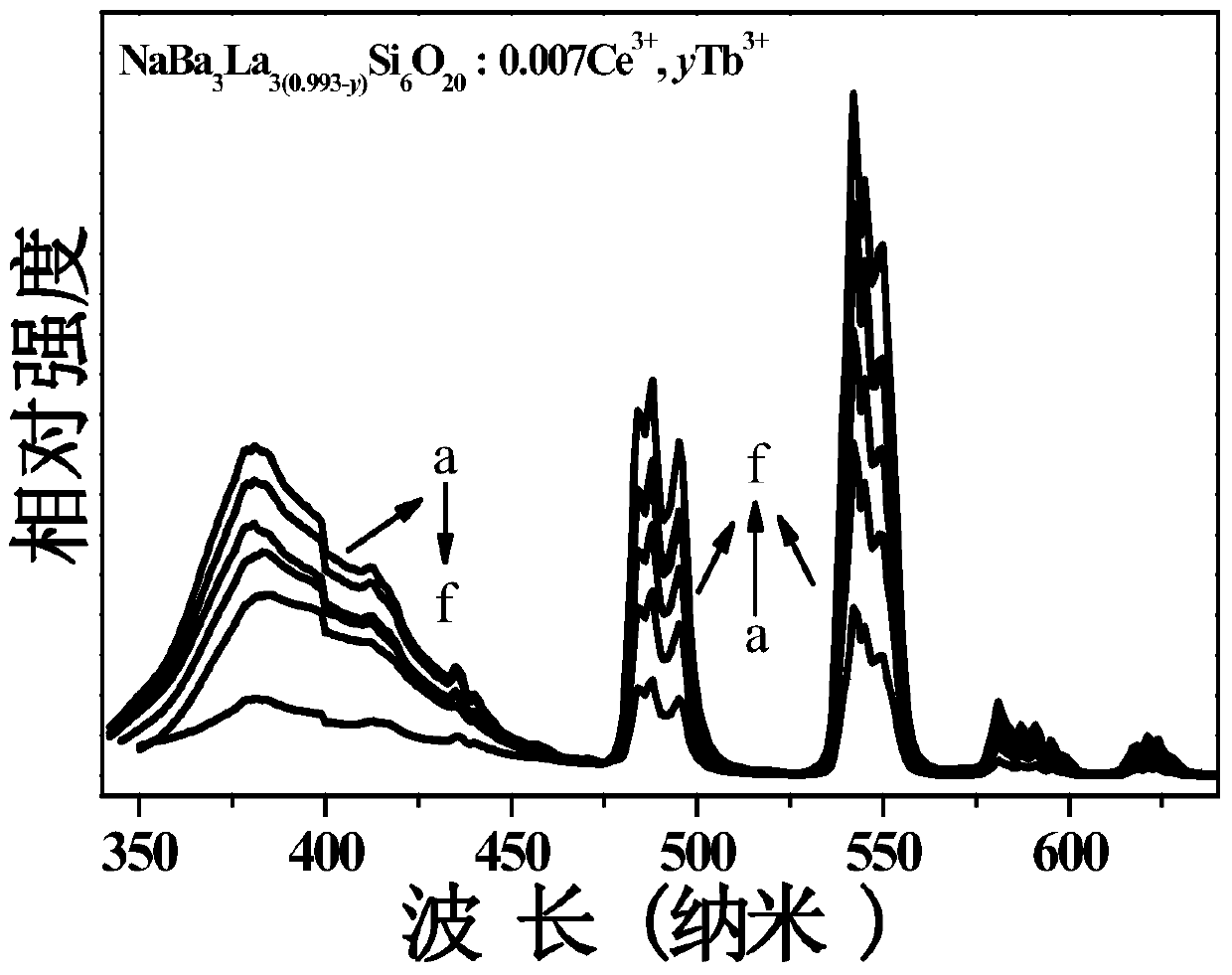

[0036] Under the excitation of near-ultraviolet light at 335nm, the fluorescent powder material of this embodiment has stronger emission peaks at 350-460nm, weaker emission peaks at 475-510nm and 530-565nm, showing stronger blue light, see image 3 Middle a curve; its color coordinates are (0.1968, 0.2227), see ...

Embodiment 2

[0038] Weigh sodium bicarbonate (NaHCO 3 ) 0.2521g, barium nitrate (Ba(NO 3 ) 2 ) 2.3520g, tetraethyl orthosilicate 4.0237ml, lanthanum hydroxide (La(OH) 3 ) 1.5507g, ammonium cerium nitrate ((NH 4 ) 2 Ce(NO 3 ) 6 ) 0.0344g, terbium nitrate (Tb(NO 3 ) 3 ) 0.3104g, fully ground in an agate mortar and mixed evenly, pre-fired at 600°C for 24 hours in an air atmosphere, cooled to room temperature naturally, took out the sample and ground it, then sintered at 880°C for 24 hours in an air atmosphere, and cooled naturally to room temperature. The sample is taken out and ground to obtain the final product, and the composition of the obtained phosphor material is: NaBa 3 La 2.679 Ce 0.021 Tb 0.3 Si 6 o 20 .

[0039] Under the excitation of 335nm near-ultraviolet light, the phosphor material of this embodiment, compared with Example 1, has weaker emission peaks at 350-460nm, stronger emission peaks at 475-510nm and 530-565nm, and still shows stronger blue light, see ima...

Embodiment 3

[0041] Weigh sodium nitrate (NaNO 3 ) 0.2550g, barium oxide (BaCO 3 ) 1.3800g, silicon dioxide (SiO 2 ) 1.0802g, lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) 3.2850g, cerous nitrate (Ce(NO 3 ) 3 ·6H 2 O) 0.0272g, terbium oxalate (3[C 2 o 4 -2].2[Tb +3 ].H 2 (2) 0.4049g, after fully grinding and mixing in an agate mortar, pre-fired at 800°C for 10 hours in an air atmosphere, cooled to room temperature naturally, took out the sample and ground it, and then sintered it at 950°C for 10 hours in an air atmosphere. Let cool to room temperature. The sample is taken out and ground to obtain the final product, and the composition of the obtained phosphor material is: NaBa 3 La 2.529 Ce 0.021 Tb 0.45 Si 6 o 20 .

[0042] Under the excitation of 335nm near-ultraviolet light, the phosphor material of this embodiment, compared with Example 2, the 350-460nm emission peak continues to weaken, and the 475-510nm and 530-565nm emission peaks continue to strengthen, showing stronger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com