Preparation method, product and application of yellow carbon (nitrogen) quantum dots containing red and green dual colors

A quantum dot and yellow technology, which is applied in the field of preparation of yellow carbon quantum dots, can solve the problem of low display index, achieve the effect of improving color rendering index, continuously adjustable color temperature, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The emission of carbon (nitrogen) quantum dots is regulated by controlling the ratio of o-phenylenediamine to benzoic acid.

[0069] According to the ingredients shown in Table 1, various raw materials were weighed, and after fully stirring and dissolving, they were put into the inner liner of the reaction kettle made of polytetrafluoroethylene. Put it in a drying box, keep it at 180 °C for 10 h according to the process shown in Table 1, and naturally cool it to room temperature. In this embodiment, the polar organic solvent is ethanol, the amount of ethanol is 20 ml, and the mass percentage of o-phenylenediamine in the solvent is 0.94%.

[0070] After opening the reactor, the reaction product was first filtered with a 0.22 μm filter. Further, it was purified using a liquid chromatography column (using dichloromethane and methanol as solvents) to remove organic impurities. Next, dialysis was performed in ethanol using a 1-50KD dialysis bag, and the quantum dots were t...

Embodiment 2

[0075] Controlled luminescence by reaction temperature

[0076] The difference between the preparation method of this example and Example 1 is shown in Table 2.

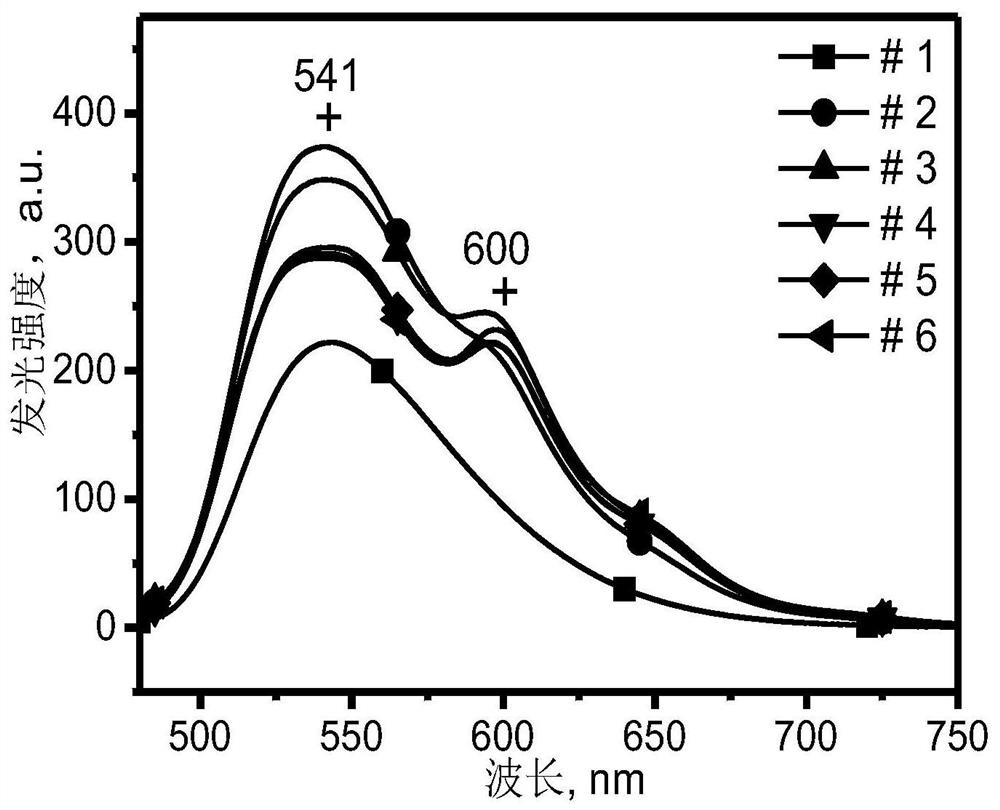

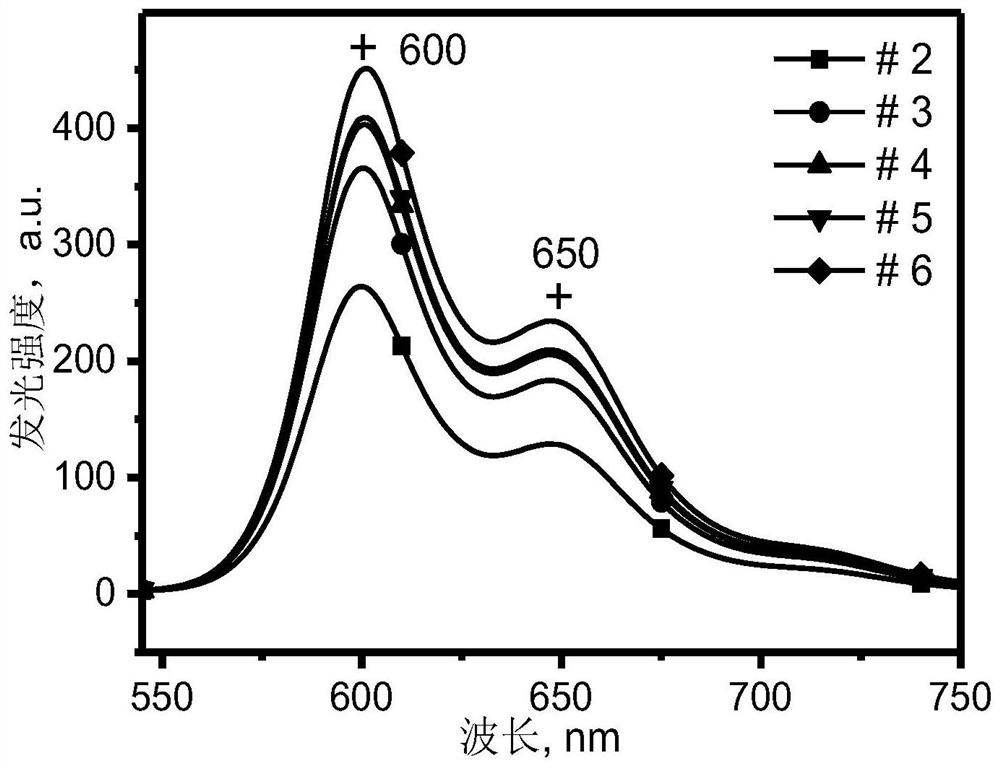

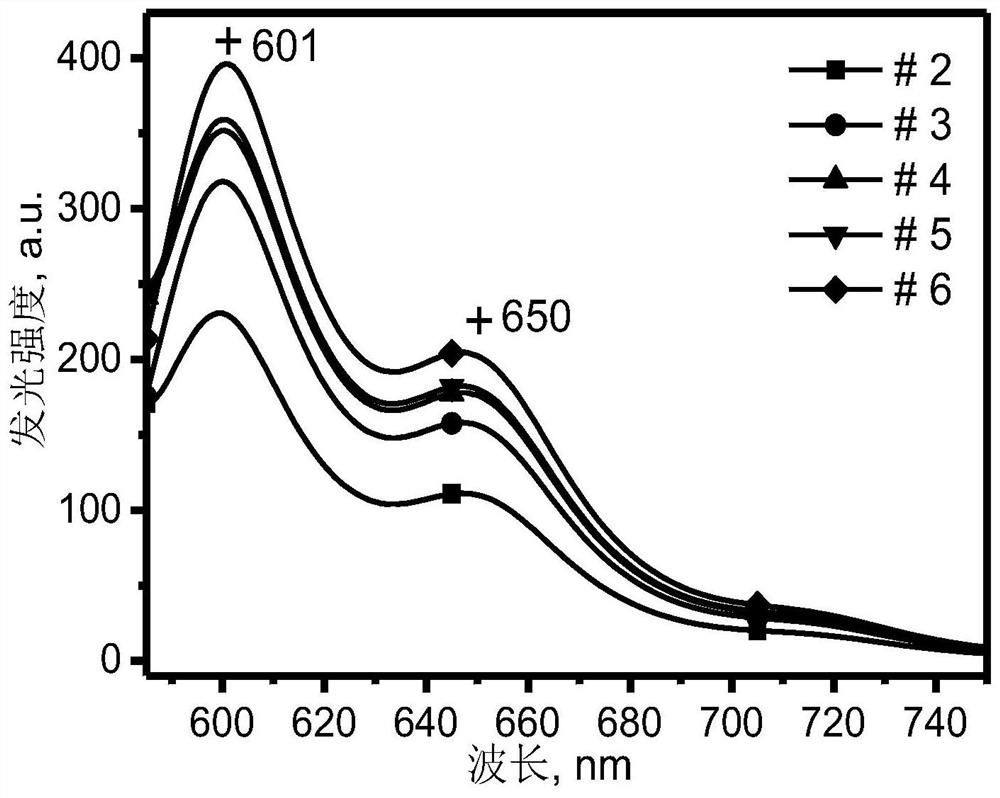

[0077] The emission spectra of the synthesized carbon (nitrogen) quantum dots under excitation at 365, 472, 538 and 572 nm in this example are as follows Figure 7-Figure 10 shown. and Figure 1-4 By comparison, it can be found that under the conditions of the same composition and the same excitation wavelength, with the increase of temperature, the relative intensity of the green light component with the emission wavelength peak at about 541 nm weakens, while the relative intensity of the red light component with emission wavelength peaks at 600 nm and 650 nm increases. The samples synthesized at 210 °C are the strongest, and the red light emission intensity of the samples at 220 °C is lower than that of the samples at 210 °C. Therefore, increasing the temperature within a certain range is beneficial to increase ...

Embodiment 3

[0086] Carbon (Nitrogen) Quantum Dot Fluorescent Film and White Light Source with Continuously Adjustable Color Temperature

[0087] The 3W blue light downlight produced by Shenzhen Siwot Lighting Co., Ltd. is used as the blue light excitation source. The downlight adopts Sanan Optoelectronics 5730 chip, the rated power of the chip is 0.5W, and each downlight is equipped with 6 LED lamp beads.

[0088] First, prepare a polyvinyl alcohol (PVA) aqueous solution with a mass fraction of 10%. After the PVA is completely dissolved, take the No. 9 carbon (nitrogen) quantum dots prepared in Example 2 above and add carbon to the PVA solution according to the volume ratio of 15%. (nitrogen) quantum dot solution, fully mix carbon (nitrogen) quantum dots and PVA solution evenly, after defoaming and degassing, coat the PVA solution mixed with carbon (nitrogen) quantum dots on the light guide plate, wait for the PVA solution After drying, a solid carbon (nitrogen) quantum dot fluorescent fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com