Optimized preparation method of polyimide film

A polyimide film and polyamic acid technology, applied in the chemical industry, can solve the problems of low thermal expansion coefficient, low glass transition temperature, and inability to meet the temperature requirements of flexible substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

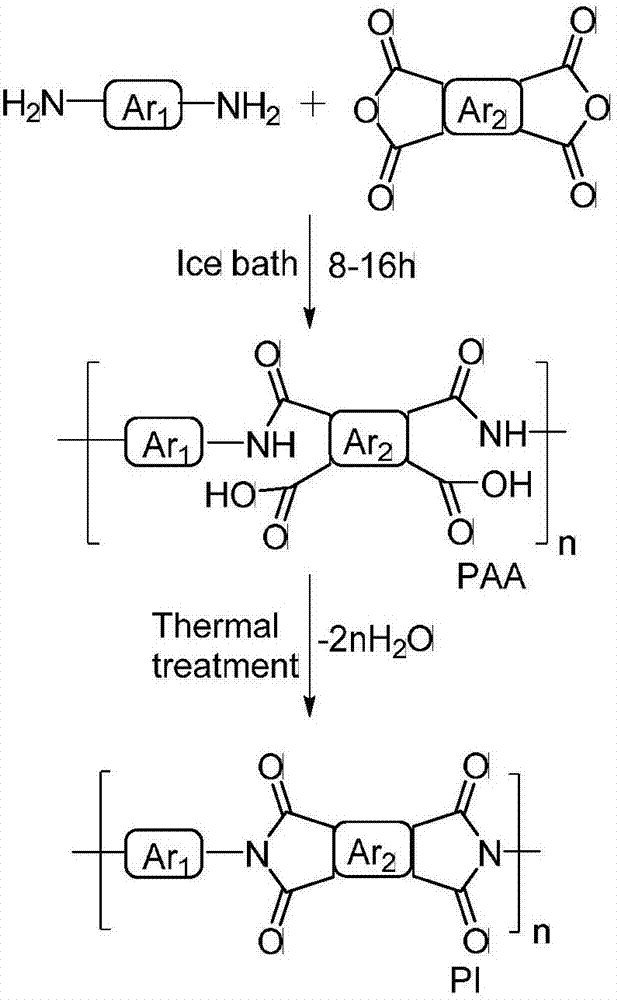

Method used

Image

Examples

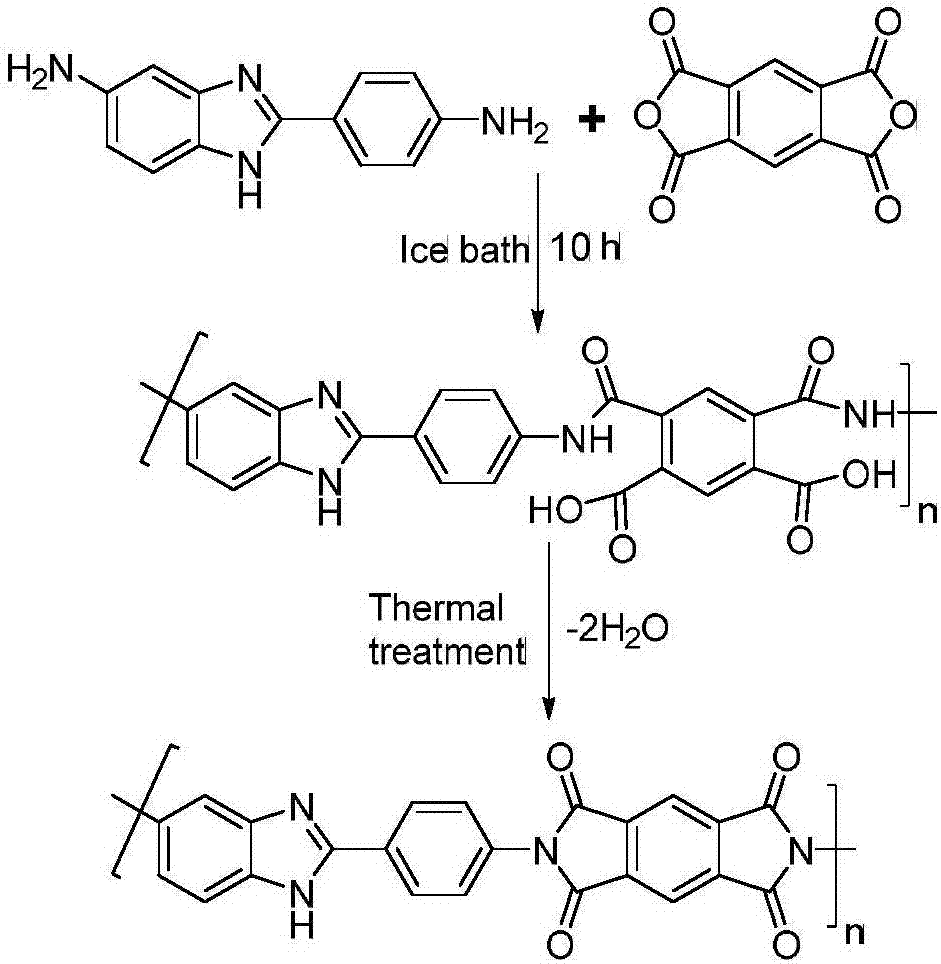

Embodiment 1

[0046] Weigh 6.73g of 2-(4-aminophenyl)-5-aminobenzimidazole and 6.55g of pyromellitic anhydride into a 250mL three-necked flask, blow Ar gas under an ice-water bath and stir mechanically. Add 60 mL of anhydrous N,N-dimethylacetamide as a solvent, and increase the viscosity as time goes on, adding 95 mL of solvent in total, and the final solid content is 8.4%wt. After a reaction time of 10 hours, remove the reaction device and seal the bottle mouth, and place it in a refrigerator at -20°C for 1 day to defoam to obtain a uniform yellow PAA glue.

[0047] Put the PAA glue solution taken out of the refrigerator at room temperature and let it return to room temperature, and the temperature of the operating table of the film coating machine rises to 70 ℃ , and place a clean and flat glass piece on the table for coating. The thickness of the film applicator is controlled at 500 μm. Transfer the coated glass sheet to a blast oven, and pre-bake it according to the temperature rise p...

Embodiment 2

[0057] Weigh 6.73g of 2-(4-aminophenyl)-5-aminobenzimidazole, 2.62g of pyromellitic anhydride and 5.30g of 3,3',4,4'-biphenyltetracarboxylic anhydride (pyromellitic anhydride Formic anhydride: 3,3',4,4'-biphenyltetracarboxylic anhydride = 2:3) was added into a 250 mL three-necked flask, and Ar gas was introduced under an ice-water bath and stirred mechanically. Add 60mL of anhydrous N,N-dimethylacetamide as a solvent, the viscosity becomes larger as time goes on, add 80mL of solvent in sequence, and the final solid content is 9.8%wt. After a reaction time of 14 hours, the reaction device was removed and the bottle mouth was sealed, and it was placed in a refrigerator at -20°C for 1 day to defoam, and a uniform yellow PAA glue was obtained.

[0058] Put the PAA glue solution taken out of the refrigerator at room temperature and let it return to room temperature, and the temperature of the operating table of the film coating machine rises to 70 ℃ , and place a clean and flat gl...

Embodiment 3

[0068] Weigh 4.51g of 2-(4-aminophenyl)-5-aminobenzimidazole and 5.89g of 3,3',4,4'-biphenyltetracarboxylic anhydride into a 150mL three-neck flask, Ar gas, add the solvent anhydrous N,N-dimethylacetamide 60mL. The solid content was 15.6%wt. After 12 hours of reaction time, the reaction device was removed and the bottle mouth was sealed, and it was placed in a refrigerator at -20°C for 1 day to remove bubbles, and a uniform yellow PAA glue was obtained.

[0069] Put the PAA glue solution taken out of the refrigerator at room temperature and let it return to room temperature. The temperature of the operating table of the film coating machine is raised to 70°C, and a clean and flat glass sheet is placed on the table for coating. The thickness of the film applicator is controlled at 500 μm. Transfer the coated glass sheet to a blast oven, and pre-bake it according to the temperature rise program of 70°C / 2h, 90°C / 2h, 110°C / 2h, 130°C / 2h, 150°C / 2h, 180°C / 2h to remove solvent. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| 5% thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com