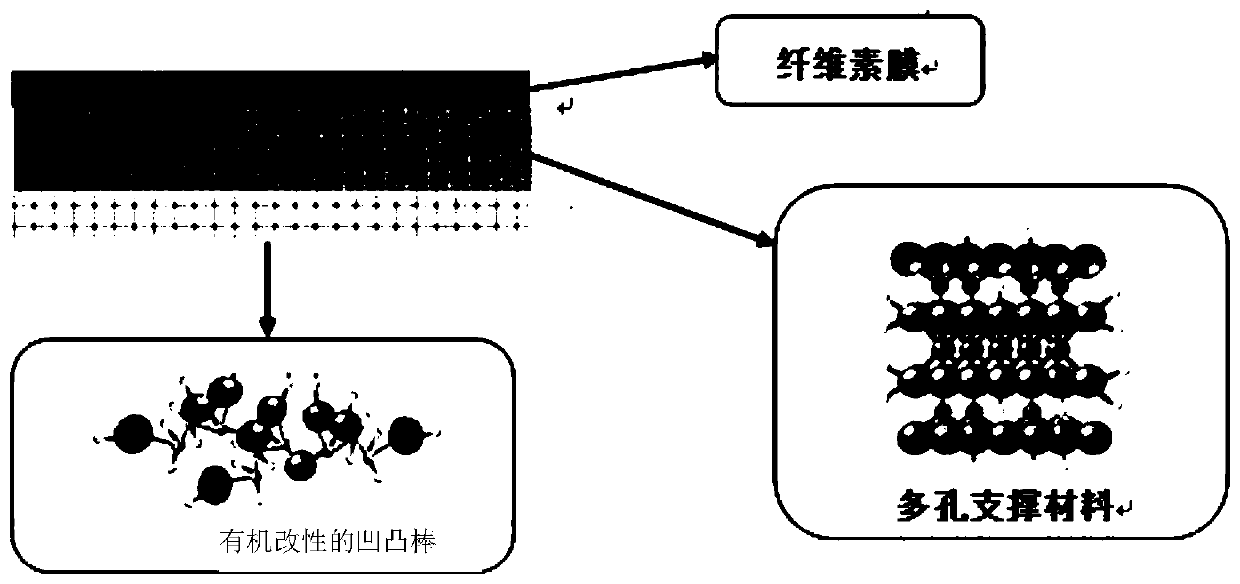

A preparation method of double-skin forward osmosis membrane material using attapulgite as porous support material

A technology of forward osmosis membrane and porous support, which is applied in the field of preparing double-skinned forward osmosis membranes, can solve the problems of high cost of nanotubes, large concentration polarization of asymmetric forward osmosis membranes, unfavorable water permeability of forward osmosis membranes, etc., to achieve increased Large pore volume, the effect of improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

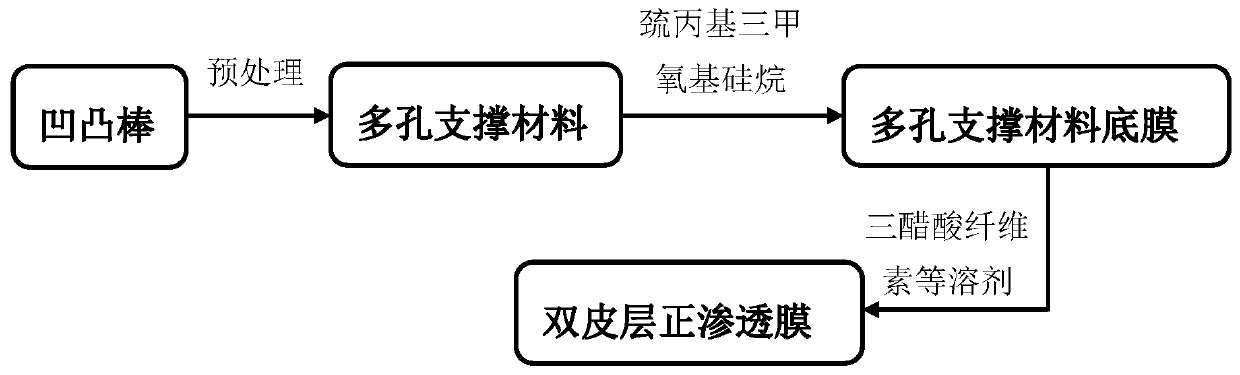

[0027] The preparation method of the double-skinned forward osmosis membrane material using the attapulgite as the porous support material of the present invention comprises the following steps:

[0028] (1) Attapulgite pretreatment, the specific process is: take the attapulgite and grind it through a 100-300 mesh sieve, add 2-6mol / L hydrochloric acid, and the solid-liquid ratio of the attapulgite to hydrochloric acid is 1:5g / mL~1: 15g / mL, mechanically stirred at room temperature for 40-60min, filtered, washed with distilled water until neutral, then dried at 100-110°C, cooled, ground, and passed through a 100-300 mesh sieve to obtain pretreated attapulgite .

[0029] (2) Prepare the organically modified attapulgite with the pretreated attapulgite as the porous support material, and the specific steps are: (a) take the attapulgite after the pretreatment in the flask, and add distilled water, the solid-liquid of the attapulgite and distilled water The ratio is 1:50g / mL~1:150g / ...

Embodiment 1

[0032] (1) Attapulgite pretreatment, the specific process is as follows: take 2g of attapulgite and grind it through a 100-mesh sieve, add 10mL of 2mol / L hydrochloric acid, stir mechanically at room temperature for 40min, filter, wash with distilled water until neutral, and place at 100°C drying, cooling, grinding, and passing through a 100-mesh sieve to obtain a pretreated attapulgite.

[0033](2) Using attapulgite as a porous support material to prepare organically modified attapulgite, the specific steps are: (a) take 1 g of pretreated attapulgite in a flask, and add 50 mL of distilled water. (b) Stir the solution in step (a) and heat to reflux for 1 h, then cool and filter, then transfer the wet attapulgite to a dry and clean flask, and then add 50 mL of ethanol and 3 mL of mercaptopropyltrimethoxysilane. (c) Use 1mol / L HCl to adjust the pH of the solution prepared in step (b) to 5.5, heat to reflux for 4 hours, filter the solution after cooling to 20°C, and finally rinse ...

Embodiment 2

[0036] (1) Attapulgite pretreatment, the specific process is as follows: take 4g of attapulgite and grind it through a 150-mesh sieve, add 35mL of 3mol / L hydrochloric acid, stir mechanically at room temperature for 55min, filter, wash with distilled water until neutral, and place at 105°C drying, cooling, grinding, and passing through a 150-mesh sieve to obtain a pretreated attapulgite.

[0037] (2) Using attapulgite as a porous support material to prepare organically modified attapulgite, the specific steps are: (a) take 1 g of pretreated attapulgite in a flask, and add 100 mL of distilled water. (b) Stir the solution in step (a) and heat to reflux for 1.3h, then cool and filter, then transfer the wet attapulgite to a dry and clean flask, then add 80mL of ethanol and 4.5mL of mercaptopropyltrimethoxysilane . (c) Use 1mol / L HCl to adjust the pH of the solution prepared in step (b) to 6.5, then heat to reflux for 5h, cool to 22°C and filter the solution, and finally rinse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com