Method and device for assisting supersonic vibration in laser cladding

A technology of ultrasonic vibration and auxiliary laser, which is applied in the field of laser processing to achieve the effect of simple structure, quality assurance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

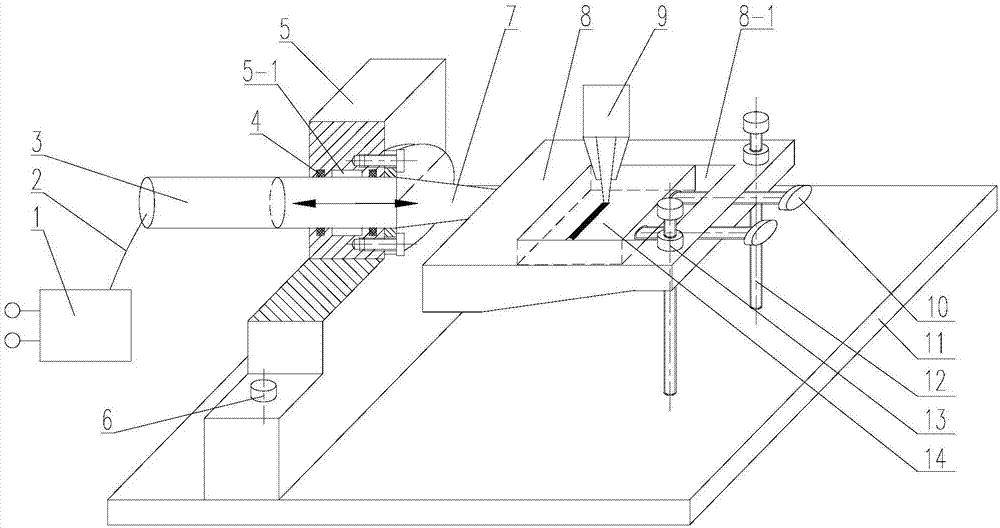

[0036] Such as figure 1 with 2 As shown, a device for ultrasonic vibration assisted laser cladding, the device includes a base 11, an ultrasonic vibration system, a support 5 and a supporting plate 8;

[0037] The ultrasonic vibration system includes an ultrasonic generator 1 for outputting ultrasonic frequency current, a transducer 3 for converting ultrasonic frequency current into mechanical vibration, and a horn 7 for increasing the amplitude of mechanical vibration. The ultrasonic generator 1 passes The cable 2 is connected to the transducer 3, and the transducer 3 is fixedly connected to the horn 7;

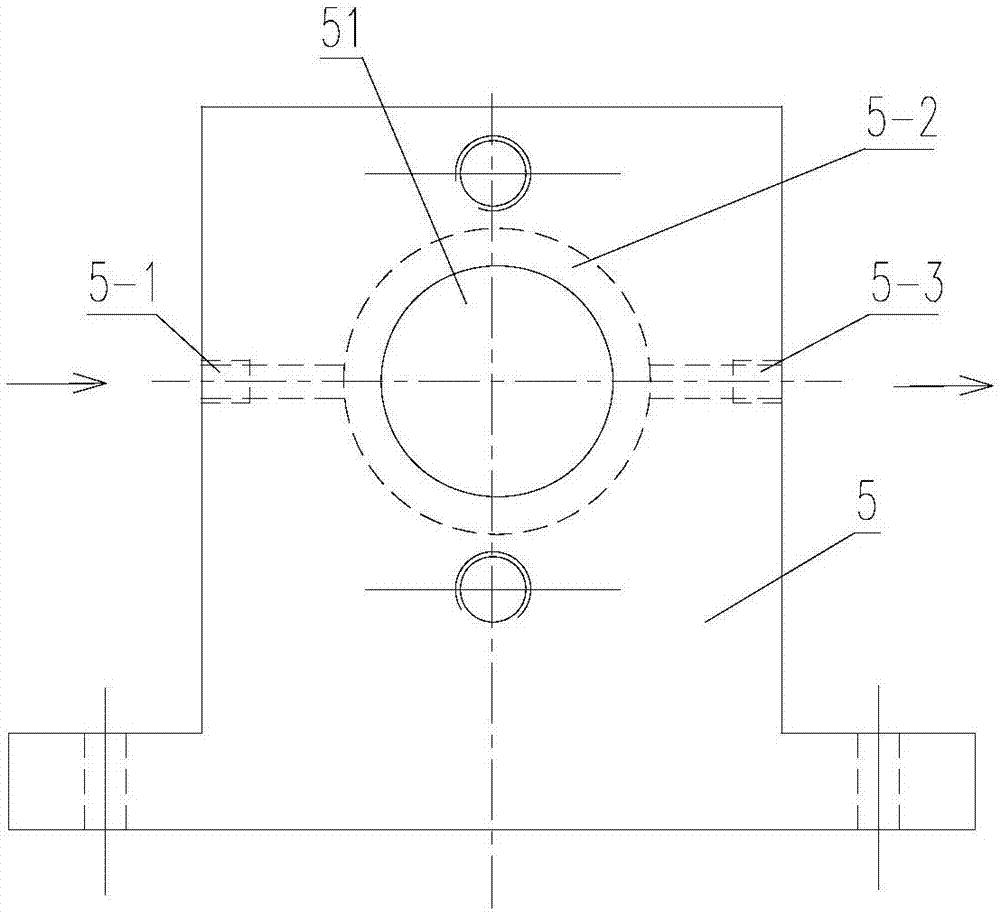

[0038] The support 5 is fixed on the base 11 through the fixing screw 6, and the horn 7 is fixed on the support 5;

[0039] The upper surface of the supporting plate 8 is provided with a prefabricated groove 8-1 for placing the cladding part 14, and the end of the horn 7 away from the transducer 3 is fixedly connected with the supporting plate 8, and the upper part of the ...

Embodiment 2

[0049] A method for ultrasonic vibration-assisted laser cladding, the method is that the laser beam transmitted by the laser cladding head 9 is irradiated on the cladding part 14 along the vertical direction, and at the same time, the ultrasonic vibration acts indirectly on the laser molten pool along the horizontal direction, A cladding layer is formed on the cladding part 14 , where the laser cladding head 9 irradiates on the cladding part 14 , and a laser molten pool will be formed on the irradiated area on the upper surface of the cladding part 14 .

[0050] Specifically, the steps of the method are:

[0051] a. First, after the cladding part 14 is polished, it is ultrasonically cleaned with acetone, and then dried with hot air;

[0052] b. Then fix the pretreated cladding part 14 in the prefabricated groove 8-1 of the supporting plate 8, and apply coupling agent on the bonding surface of the cladding part 14 and the supporting plate 8;

[0053] c. Dry the cladding powder...

Embodiment 3

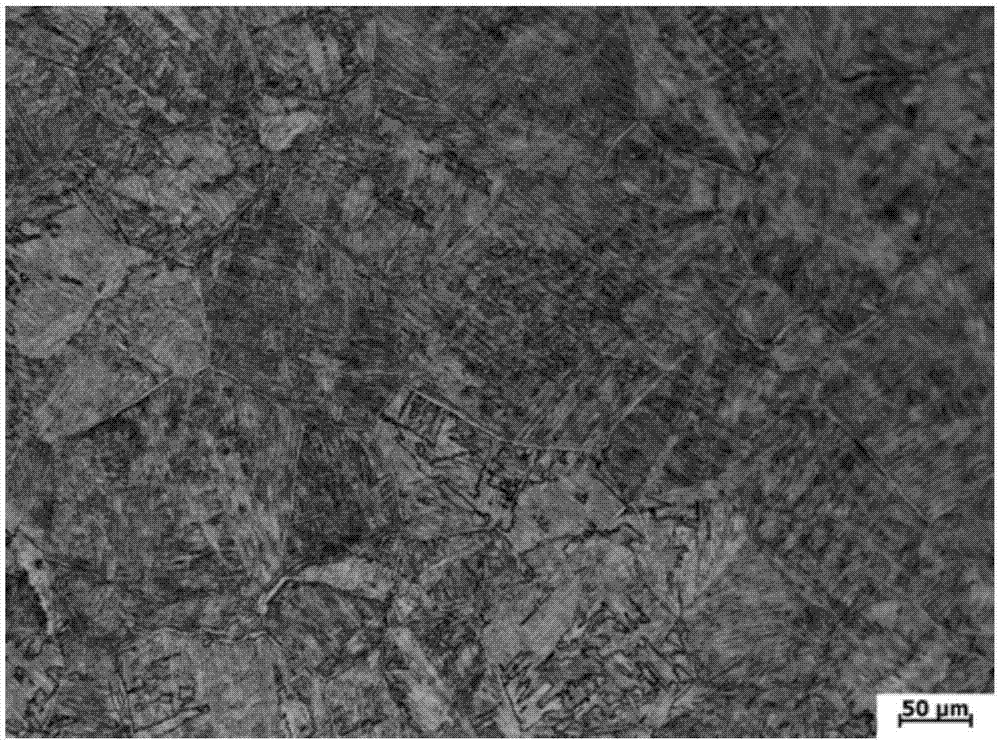

[0056] Taking the laser cladding of titanium alloy plate as an example, the above method of ultrasonic vibration assisted laser cladding is explained:

[0057] First prefabricate a 45mm×12mm×1mm slot on a 62.5mm×60mm×10mm TC4 titanium alloy plate, polish it with sandpaper, then use acetone to ultrasonically degrease it for 15 minutes, then dry it with hot air, and put the pretreated TC4 titanium alloy plate Put it in the prefabricated groove 8-1 of the supporting plate 8, and press it with the compression screw 10, and apply coupling agent on the bonding surface of the two;

[0058] The laser cladding powder is TC4 titanium alloy spherical powder with a particle size of 75-120 μm. Before cladding, the titanium alloy powder must be dried under vacuum conditions at about 110 ° C to prevent pores in the cladding layer;

[0059] The output frequency of ultrasonic generator 1 is set to 38KHz. The 4Kw fiber laser processing system consists of YLS-4000 fiber laser, TWIN PF 2 / 2-MF pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com