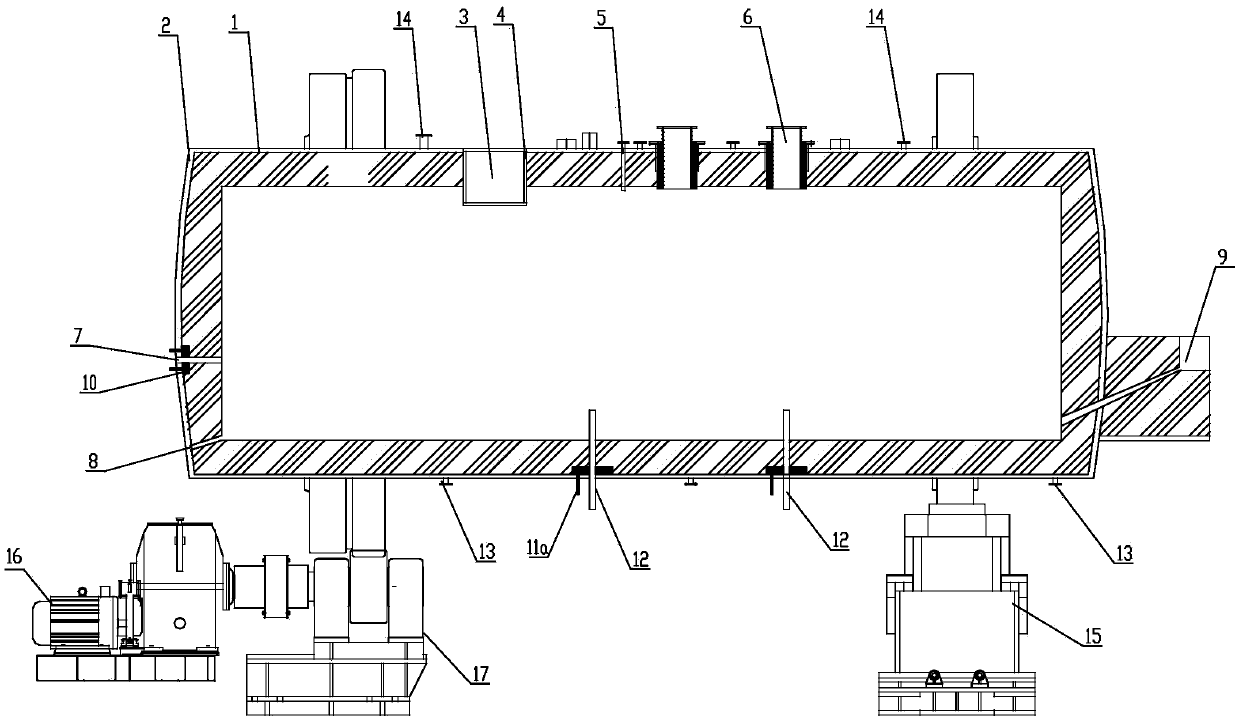

Oxygen-enriched oxidation smelting method and device for antimony-containing material

An oxidation smelting and oxygen-enriching technology, which is applied in the direction of improving process efficiency, can solve the problems of unfavorable recycling and comprehensive utilization, the smelting process cannot be strengthened, and the concentration of sulfur dioxide is low, so as to achieve good environmental protection effect, strong adaptability of raw materials, The effect of improving the processing capacity of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

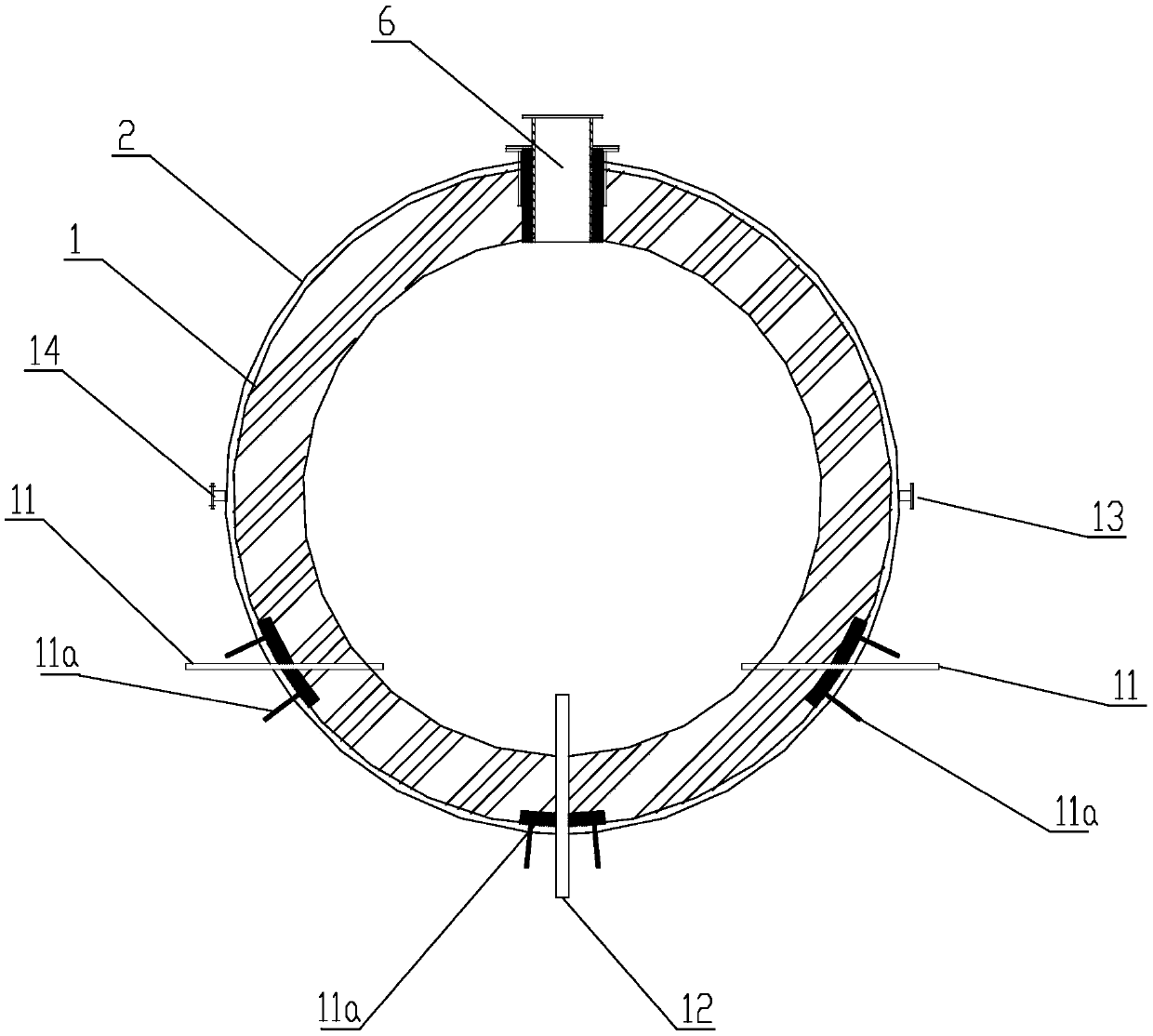

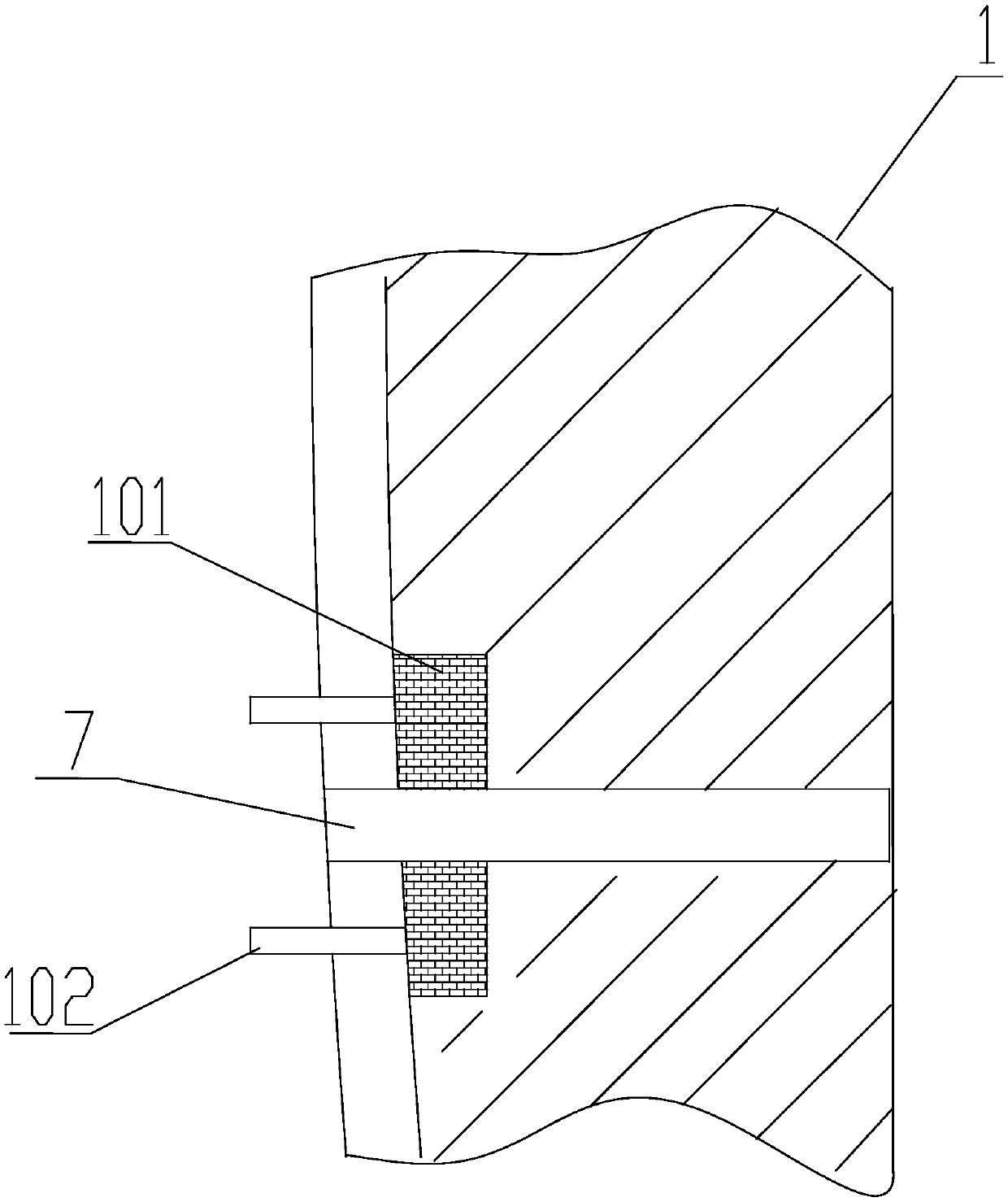

[0044] An oxygen-enriched oxidation smelting method for antimony-containing materials, comprising the steps of:

[0045] (1) Mixing: after the brittle sulfur-lead-antimony concentrate is pulverized, add iron ore, limestone, quartz sand and mix uniformly to obtain a mixed material; the weight ratio of the antimony-containing material, iron ore, limestone and quartz sand is :100:1:30:18, limestone contains 70% CaO, quartz sand contains SiO 2 was 86%,;

[0046] (2) Granulation: the mixed material is granulated by a disc granulator, the particle diameter of the pellets is 15mm, and the water content is 10%, and is sent into the oxygen-enriched oxidation smelting device by a belt conveyor. The furnace temperature of the oxygen-enriched oxidation smelting unit is 1000°C;

[0047] (3) Blowing in air: after the thermal decomposition of the mixed material for 1min, the oxygen produced by the air separation oxygen production equipment is transported to the air duct at the rear end of ...

Embodiment 2

[0051] An oxygen-enriched oxidation smelting method for antimony-containing materials, comprising the steps of:

[0052] (1) Mixing materials: After the antimony sulfide concentrate is crushed, add iron ore, limestone, and quartz sand and mix evenly to obtain a mixed material; the weight ratio of the antimony-containing material, iron ore, limestone, and quartz sand is: 100 :5:25:23, limestone contains 85% CaO, quartz sand contains SiO 2 90%;

[0053] (2) Granulation: the mixed material is granulated by a disc granulator, the particle diameter of the spheres is 20 mm, and the water content is 8%, and is sent into the oxygen-enriched oxidation smelting device by a belt conveyor. The furnace temperature of the oxygen-enriched oxidation smelting unit is 1200°C;

[0054] (3) Blowing in air: after the thermal decomposition of the mixed material for 5 minutes, the oxygen produced by the liquid oxygen vaporization device is transported through the pipeline to the air duct at the fr...

Embodiment 3

[0058] An oxygen-enriched oxidative smelting method for antimony-containing materials, other process parameters and steps are the same as in Example 1, the difference is that antimony oxide concentrates are used as raw materials for antimony-containing materials instead of brittle sulfur-lead-antimony concentrates, antimony oxide concentrates, The weight ratio of iron ore, limestone and quartz sand is: 100:4:28:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com