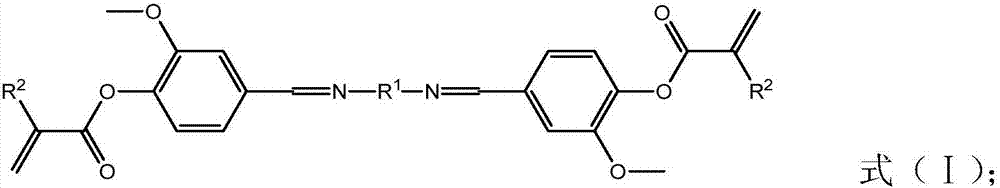

Bio-acrylic acid ester based on schiff base structure and preparation method and application thereof

A bio-based acrylate and Schiff base technology, applied in the preparation of imino compounds, organic chemistry, coatings, etc., to achieve the effects of good controllability, easy implementation, high glass transition temperature and heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

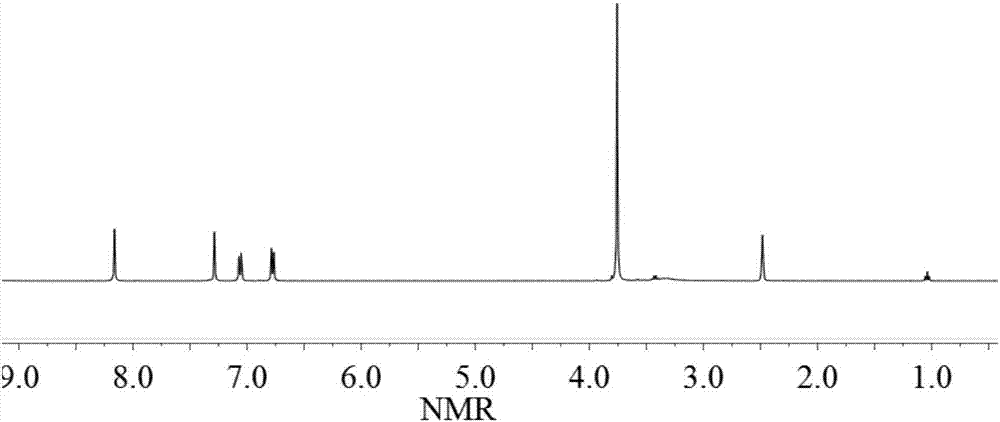

[0031] (1) Dissolve 10g of vanillin and 1.8g of ethylenediamine in 15ml of tetrahydrofuran, react at 10°C for 72 hours, cool to room temperature to precipitate a yellow precipitate, filter it with suction, wash with a small amount of ethanol, and dry it to obtain vanillin ethylenediamine Amine Schiff base. The structural formula is shown in the following formula II-1, and the yield is 95%. 1 H-NMR such as figure 1 As shown, there is a one-to-one correspondence between each peak on the figure and the hydrogen above the structure of formula II-1.

[0032]

[0033] (2) Dissolve 10 g of vanillin ethylenediamine Schiff base and 12.3 g of acryloyl chloride in 7 ml of butyl acetate, and stir with a magnet. Subsequently, 0.48g of triethylamine was dissolved in 7ml of butyl acetate, and added dropwise through a constant pressure separatory funnel. After 1h, the temperature was raised to 10°C for 70h. After the reaction is complete, add 10ml of sodium bicarbonate aqueous solution ...

Embodiment 2

[0036] (1) Dissolve 10g of vanillin and 1.4g of butanediamine in 30ml of tetrahydrofuran, react at 20°C for 60h, cool to room temperature to precipitate a yellow precipitate, filter with suction, wash with a small amount of ethanol, and dry it to obtain butanediamine mat husband base. The structural formula is shown in the following formula II-2, and the yield is 92%.

[0037]

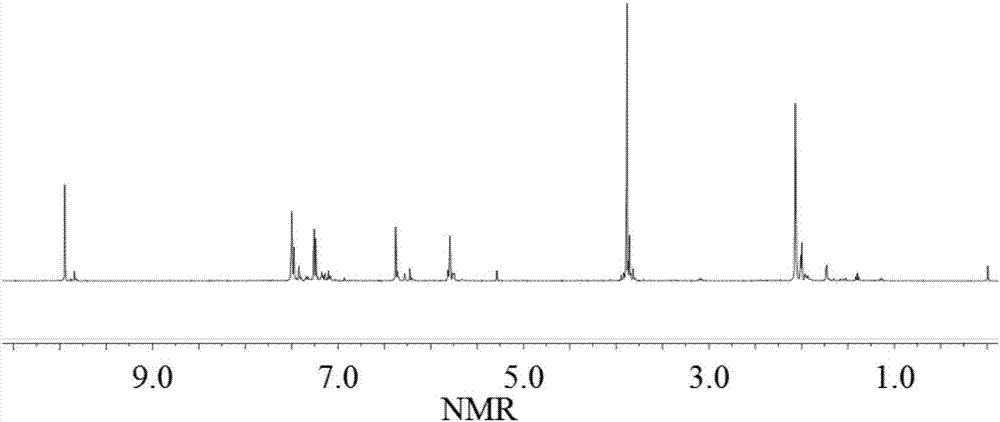

[0038] (2) Dissolve 10g of Schiff's base and 20.5g of acryloyl chloride in 15ml of ethanol, and stir with a magnet. Subsequently, 0.8 g of triethylamine was dissolved in 15 ml of ethanol, and added dropwise through a constant pressure separatory funnel. After 1 hour, the temperature was raised to 20° C. for 65 hours. After the reaction is complete, add 20ml of sodium bicarbonate aqueous solution and stir for half an hour to remove excess acryloyl chloride, then pour the mixed solution into a separatory funnel and wash with water three times to remove acrylic acid and triethylamine, and then distill...

Embodiment 3

[0041] (1) Dissolve 10g of vanillin and 0.76g of hexamethylenediamine in 50ml of tetrahydrofuran, react at 30°C for 50h, cool to room temperature to precipitate a yellow precipitate, filter with suction, wash with a small amount of ethanol, and dry it to obtain hexamethylenediamine mat husband base. The structural formula is shown in the following formula II-3, and the yield is 91%.

[0042]

[0043] (2) Dissolve 10 g of hexamethylenediamine Schiff base and 44.9 g of acryloyl chloride in 25 ml of tetrahydrofuran, and stir with a magnet. Subsequently, 0.86 g of triethylamine was dissolved in 25 ml of tetrahydrofuran, and added dropwise through a constant pressure separatory funnel. After 1 hour, the temperature was raised to 30° C. for 55 hours. After the reaction is complete, add 30ml of sodium bicarbonate aqueous solution and stir for half an hour to remove excess acryloyl chloride, then pour the mixed solution into a separatory funnel and wash with water three times to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com