Positive plate of lead storage battery and preparation method thereof

A lead-acid battery and positive plate technology, applied in lead-acid battery electrodes, lead-acid batteries, electrode manufacturing, etc., can solve the problems of difficulty in controlling particle size and content, affecting battery performance, etc., to improve battery life and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Select two different lead pastes and mix them at a mixing ratio of 1:10. After assembling the battery, conduct a life comparison experiment and perform the following experiments.

[0037] A production of high content 4BS lead paste

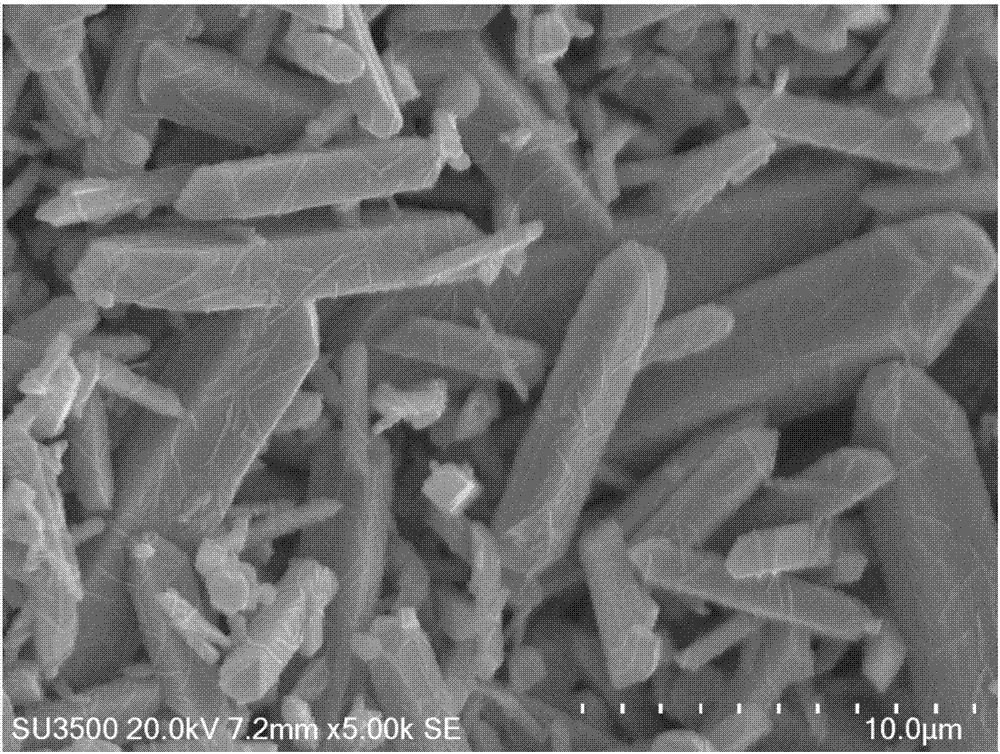

[0038]First, add 100Kg of lead powder into the vacuum paste machine, add 70g of fiber to the lead powder, dry stir for 3 minutes, add 12 liters of water, stir for another 3 minutes, then add acid, the specific gravity of the acid is 1.4, and the amount of acid is 10kg. Adjust the angle of the acid feeding nozzle, control the acid adding time at 5 minutes, and set the highest temperature to 80°C, set the vacuum degree of the vacuum paste machine at 483.8mbar, and then keep it for 10 minutes during the stirring process, so that A lead paste with a content of 50% 4BS is formed, and the control time is 10 minutes to avoid excessive growth of 4BS crystal grains. The formed product was observed under a scanning electron microscope, as figure 1 ...

Embodiment 2

[0047] Select two different lead pastes and mix them at a ratio of 1:1. After assembling the battery, conduct a life comparison experiment and perform the following experiments.

[0048] A production of high content 4BS lead paste.

[0049] First, add 100Kg of lead powder into the vacuum paste machine, add 70g of fiber to the lead powder, dry stir for 3 minutes, add 12 liters of water, stir for another 3 minutes, then add acid, the specific gravity of the acid is 1.4, and the amount of acid is 10kg. Adjust the angle of the acid nozzle, control the acid addition time within 5 minutes, and set the highest temperature to 80 degrees, set the vacuum degree of the vacuum paste machine at 483.7mbar, and then keep it for 10 minutes during the stirring process, so that A lead paste with a content of 50% 4BS is formed, and the control time is 10 minutes to avoid excessive growth of 4BS crystal grains.

[0050] B contains additive Sb 2 o 3 or SnSO 4 Production of lead paste

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com