Method for preparing lithium titanate cathode material for lithium ion power batteries

A technology for power batteries and negative electrode materials, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve problems such as difficulty in industrial production, uneven mixing of solid-phase methods, and poor control of lithium-titanium stoichiometric ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

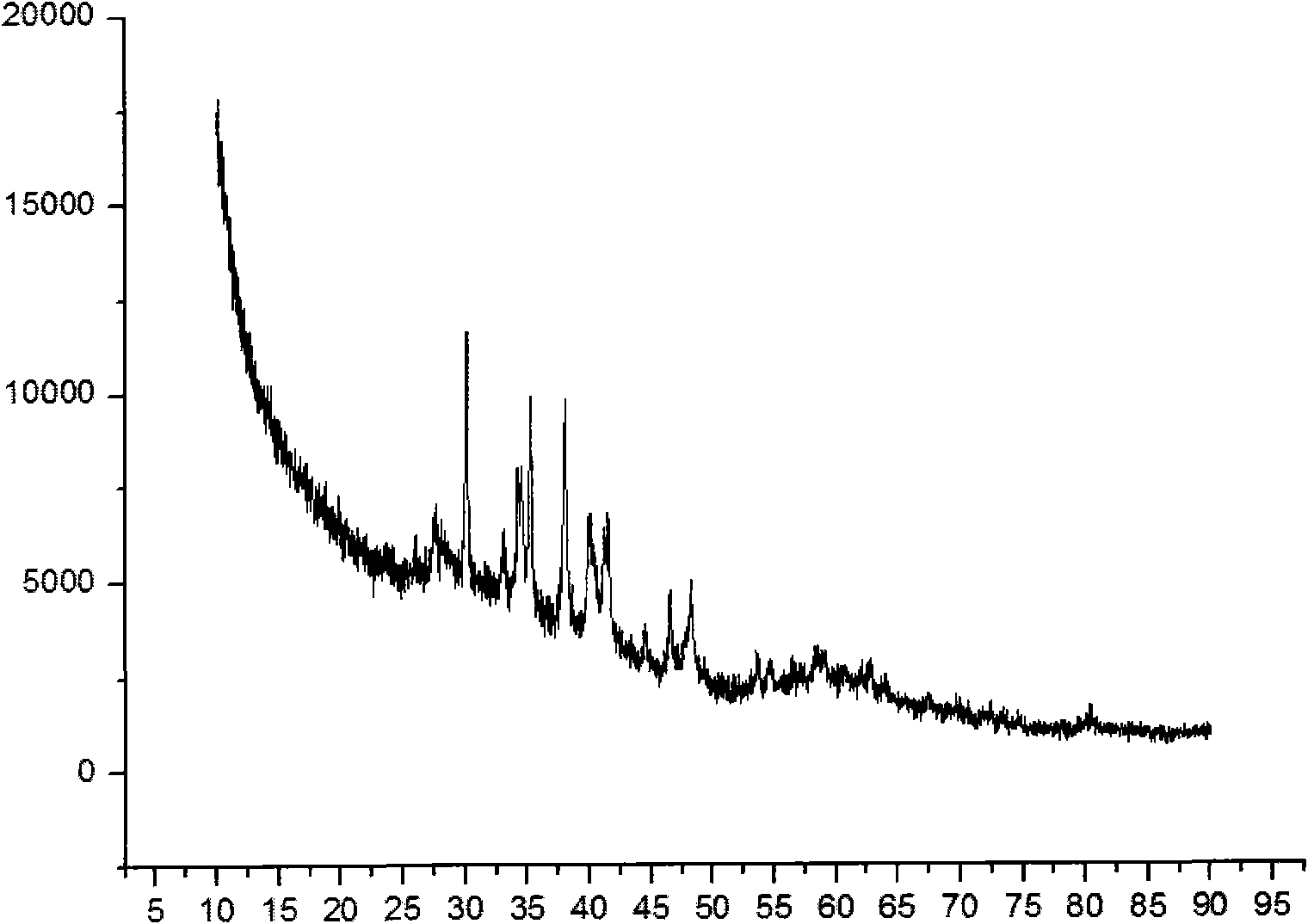

[0028] Lithium hydroxide is formulated into a solution with a concentration of 10%, and nano-titanium dioxide powder mixed with Zr (or Sn, Ni, etc.) %), mix evenly, pour in 2L autoclave, carry out hydrothermal reaction. Hydrothermal reaction temperature: 150°C, reaction time: 48hr, autoclave pressure: 0.4Mpa. The slurry obtained by hydrothermal treatment was subjected to spray drying treatment, and the powder obtained after treatment was sample A.

Embodiment 2

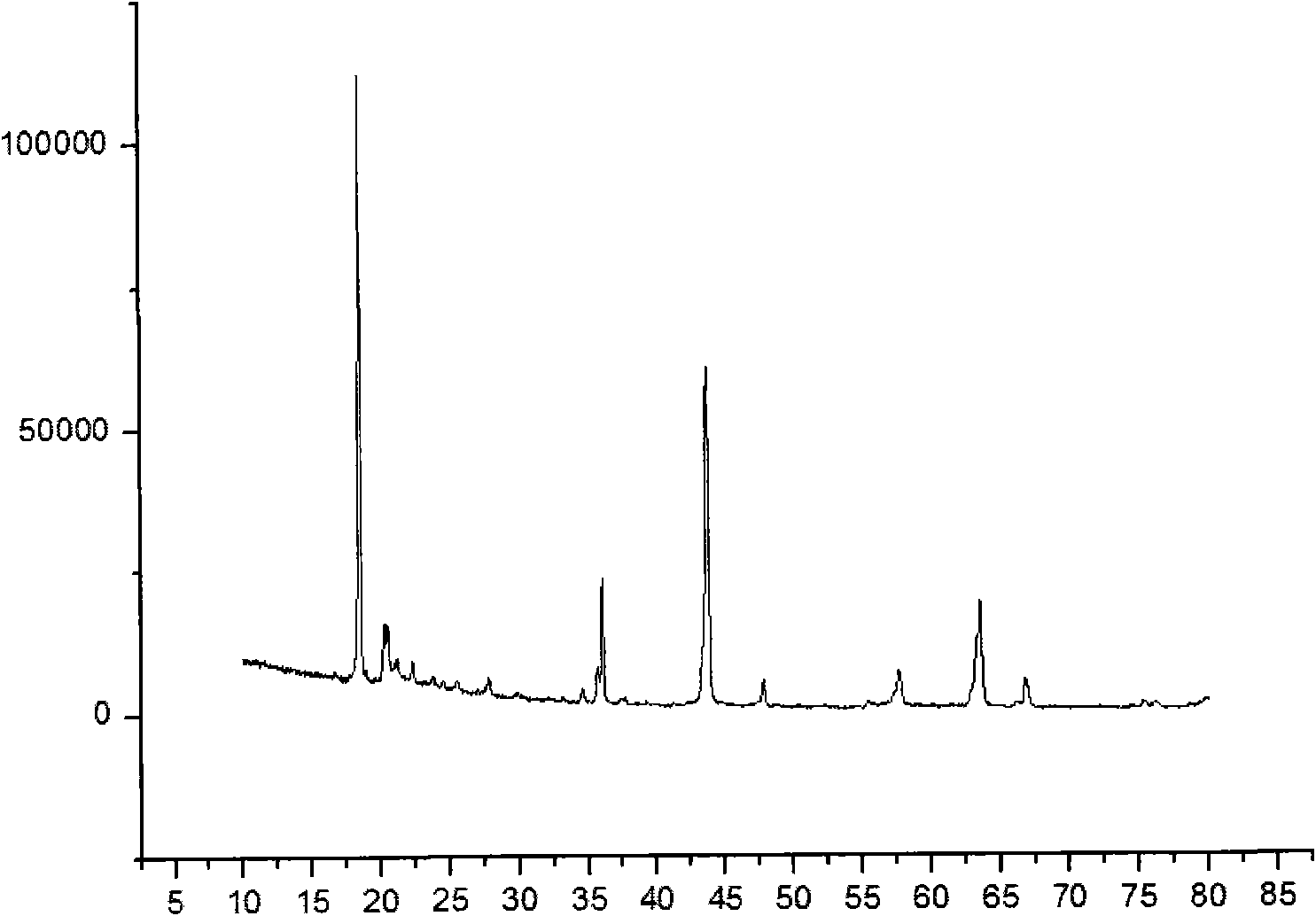

[0030] Lithium hydroxide is formulated into a solution with a concentration of 10%, and nano-titanium dioxide powder mixed with Zr (or Sn, Ni, etc.) %), mix evenly, pour in 2L autoclave, carry out hydrothermal reaction. Hydrothermal reaction temperature: 150°C, reaction time: 48hr, autoclave pressure: 0.4Mpa. The slurry obtained by hydrothermal treatment was spray-dried, and the powder obtained after the treatment was roasted in a high-temperature furnace at 700°C for 20 hours, and the obtained sample was B.

Embodiment 3

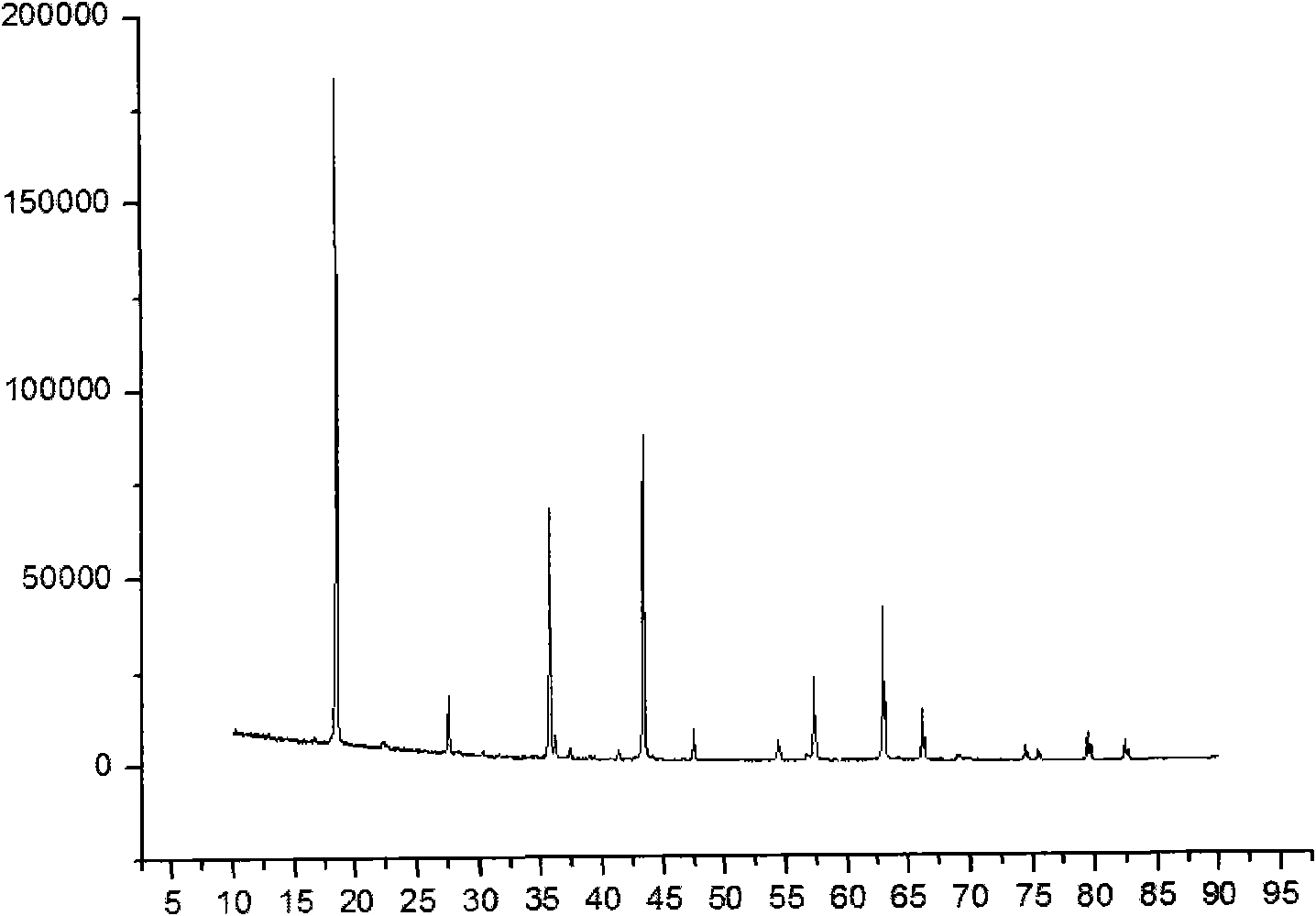

[0032] Lithium hydroxide is formulated into a solution with a concentration of 8%, and nano-titanium dioxide powder mixed with Zr (or Sn, Ni, etc.) %), mix evenly, pour in 2L autoclave, carry out hydrothermal reaction. Hydrothermal reaction temperature: 180°C, reaction time: 36hr, autoclave pressure: 0.9Mpa. The slurry obtained by hydrothermal treatment was spray-dried, and the powder obtained after the treatment was roasted in a high-temperature furnace at 800°C for 20 hours, and the obtained sample was C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com