Aluminum alloy for automobile body and preparing method and application of aluminum alloy

A technology of automobile body and aluminum alloy, applied in vehicle parts, transportation and packaging, superstructure, etc., can solve the problems of aluminum alloy surface corrosion, and achieve the effect of good buffer recovery ability, high hardness and strong collision absorption ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

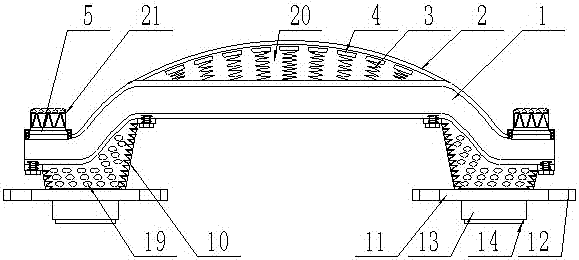

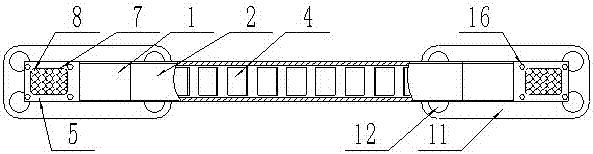

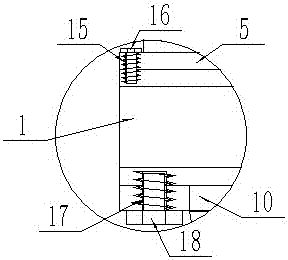

Image

Examples

Embodiment 1

[0036] The raw materials of the car body use the following components by mass percentage: Cu 1.2%, Mg 0.5%, Cr 0.5%, Si 1.8%, C 0.5%, Ti 0.3%, Be 0.1%, Ni 1.0%, Sc 0.5%, Zn 1.5%, W 1.5%, Eu0.2%, the balance is Al. In this embodiment, the method for preparing the body of the automobile body includes the following steps: first weigh each raw material component according to the above-mentioned mass percentage; then first put the weighed Al into a high-temperature furnace and heat it to 700°C to melt it completely, and then The weighed raw materials are added to the high-temperature furnace in the order of melting point, and heated until the raw materials in the furnace are completely melted. The high-temperature furnace is sealed, and the slag and gas in the melt are refined and removed; then the melt is poured into the deep well In the casting mold, cool and cast into a round cast rod; then use an extruder to extrude the heated round cast rod from the automobile body mold to form...

Embodiment 2

[0038] The raw materials of the car body use the following components by mass percentage: Cu 1.8%, Mg 0.9%, Cr0.5%, Si 2.0%, C 1%, Ti 0.3%, Be 0.1%, Ni 1.2%, Sc 0.7%, Zn 1.2%, W 1.6%, Eu0.5%, the balance is Al. In this embodiment, the method for preparing the body of the automobile body includes the following steps: first weigh the raw material components according to the above-mentioned mass percentage; then put the weighed Al into a high-temperature furnace and heat it to 750°C to melt it completely, and then The weighed raw materials are added to the high-temperature furnace in the order of melting point, and heated until the raw materials in the furnace are completely melted. The high-temperature furnace is sealed, and the slag and gas in the melt are refined and removed; then the melt is poured into the deep well In the casting mold, cool and cast into a round cast rod; then use an extruder to extrude the heated round cast rod from the automobile body mold to form an autom...

Embodiment 3

[0040] The raw materials of the car body use the following components by mass percentage: Cu 1.8%, Mg 0.3%, Cr 0.5%, Si 1.8%, C 0.8%, Ti 0.4%, Be 0.2%, Ni 1.4%, Sc 0.6%, Zn 1.4%, W 1.5%, Eu 0.4%, the balance is Al. In this embodiment, the method for preparing the body of the automobile body includes the following steps: first weigh each raw material component according to the above-mentioned mass percentage; then first put the weighed Al into a high-temperature furnace and heat it to 680°C to melt it completely, and then The weighed raw materials are added to the high-temperature furnace in the order of melting point, and heated until the raw materials in the furnace are completely melted. The high-temperature furnace is sealed, and the slag and gas in the melt are refined and removed; then the melt is poured into the deep well In the casting mold, cool and cast into a round cast rod; then use an extruder to extrude the heated round cast rod from the automobile body mold to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com