A kind of high-strength ceramic floor tile doped with coal gangue and preparation process thereof

A coal gangue and high-strength technology, which is applied in the field of high-strength ceramic floor tiles doped with coal gangue and its preparation technology, can solve the problems of limiting the utilization rate of coal gangue and low added value of products, so as to reduce the sintering temperature, save energy, reduce dependent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

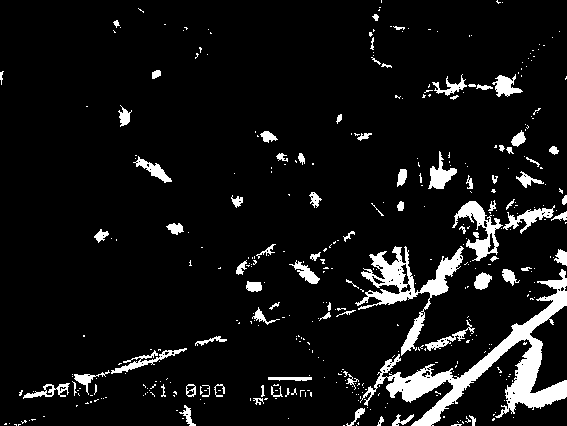

Image

Examples

Embodiment 1

[0023] A preparation process for high-strength ceramic floor tiles doped with coal gangue:

[0024] (1) Coarse crushing: bake coal gangue and boiler slag at 150°C for 4 hours, and then pass through a crusher to coarsely crush them into particles below 10mm;

[0025] (2) Fine grinding and sieving: Put the coal gangue and boiler slag particles in the ball mill for 8 hours, and then pass through a 250-mesh sieve to obtain fine powder;

[0026] (3) Mixing: Weigh 62% of coal gangue fine powder, 34% of boiler slag fine powder and 4% of molybdenum trioxide (industrial grade molybdenum trioxide) by weight percentage, and mix them in a three-dimensional mixer for 10 hours to obtain Mixture;

[0027] (4) Blank making: Take the mixed material, add distilled water, press it with a hydraulic press under a pressure of 20MPa to obtain a green compact, and dry it at 150°C;

[0028] (5) Firing: The green body dried at 150°C is put into the muffle furnace to heat up according to the following...

Embodiment 2

[0034] A preparation process for high-strength ceramic floor tiles doped with coal gangue:

[0035] (1) Coarse crushing: bake coal gangue and boiler slag at 150°C for 4 hours, and then pass through a crusher to coarsely crush them into particles below 10mm;

[0036] (2) Fine grinding and sieving: Put the coal gangue and boiler slag particles in the ball mill for 8 hours, and then pass through a 250-mesh sieve to obtain fine powder;

[0037] (3) Mixing: Weigh 69% of coal gangue fine powder, 26% of boiler slag fine powder and 5% of molybdenum trioxide (industrial grade molybdenum trioxide) by weight percentage, and mix them in a three-dimensional mixer for 10 hours to obtain Mixture;

[0038] (4) Blank making: Take the mixed material, add distilled water, press it with a hydraulic press under a pressure of 25MPa to obtain a green compact, and dry it at 150°C;

[0039] (5) Firing: The green body dried at 150°C is put into the muffle furnace to heat up according to the following...

Embodiment 3

[0045] A preparation process for high-strength ceramic floor tiles doped with coal gangue:

[0046] (1) Coarse crushing: bake coal gangue and boiler slag at 150°C for 4 hours, and then pass through a crusher to coarsely crush them into particles below 10mm;

[0047] (2) Fine grinding and sieving: Put the coal gangue and boiler slag particles in the ball mill for 8 hours, and then pass through a 250-mesh sieve to obtain fine powder;

[0048](3) Mixing: Weigh 56% of coal gangue fine powder, 38% of boiler slag fine powder and 6% of molybdenum trioxide (industrial grade molybdenum trioxide) by weight percentage, and mix them in a three-dimensional mixer for 10 hours to obtain Mixture;

[0049] (4) Blank making: Take the mixed material, add distilled water, press it with a hydraulic press under a pressure of 25MPa to obtain a green compact, and dry it at 150°C;

[0050] (5) Firing: The green body dried at 150°C is put into the muffle furnace to heat up according to the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com