A high-temperature tensile sample grinding and polishing device and its application method

A technology for tensile specimens and grinding and polishing, which is applied in the direction of grinding/polishing equipment, preparation of test samples, grinding machines, etc. It can solve the problems of difficult polishing, uneven force, and impact on results, and achieve flexible use , prevent the effect of moving and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with embodiment.

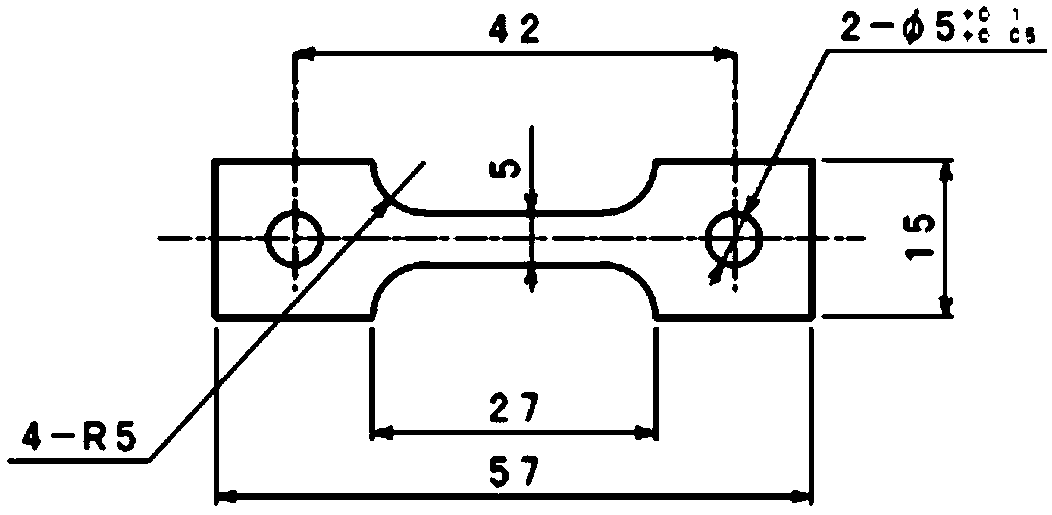

[0054] Such as figure 1 , Figure 2(a)-Figure 2(d) As shown, the high temperature tensile sample grinding and polishing device of the present invention mainly includes: grinding and polishing device main body 1, NdFeB strong magnet 2, cover 3, non-magnetic bolt 4, fixed nut 5, bolt 6, first pull Tensile sample groove 7, second tensile sample groove 8, adsorption limit device installation groove 9, diversion groove 10, tensile sample installation column 11, etc. The main body 1 and cover 3 of the grinding and polishing device are made of 304 stainless steel , the specific structure is as follows:

[0055] One side surface of the grinding and polishing device main body 1 is provided with the first tensile sample groove 7 and the second tensile sample groove 8 arranged crosswise, and in the first tensile sample groove 7 and the second tensile sample groove 8 Tensile sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com