Manufacturing method for high sensitivity semiconductor nano ultraviolet light detector

A high-sensitivity, semiconductor technology, applied in the electrical field, can solve the problems of poor photocurrent stability, slow response recovery speed, and large dark current, and achieve high-quality crystallization performance, fast response, and low dark current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

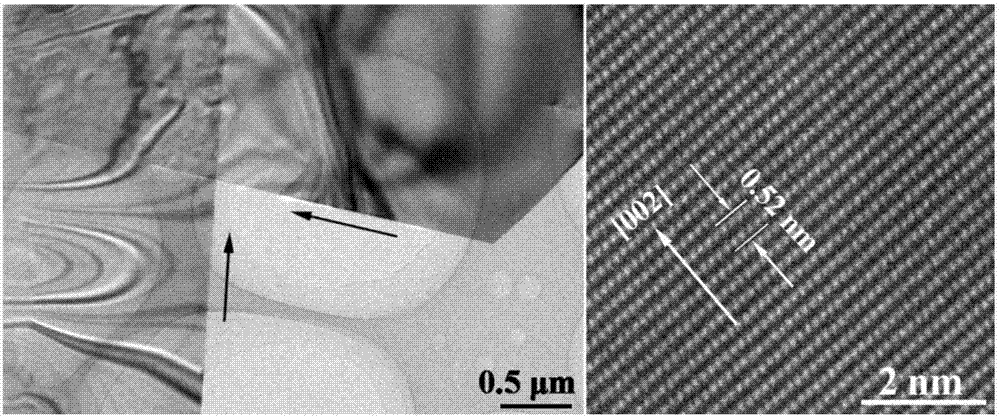

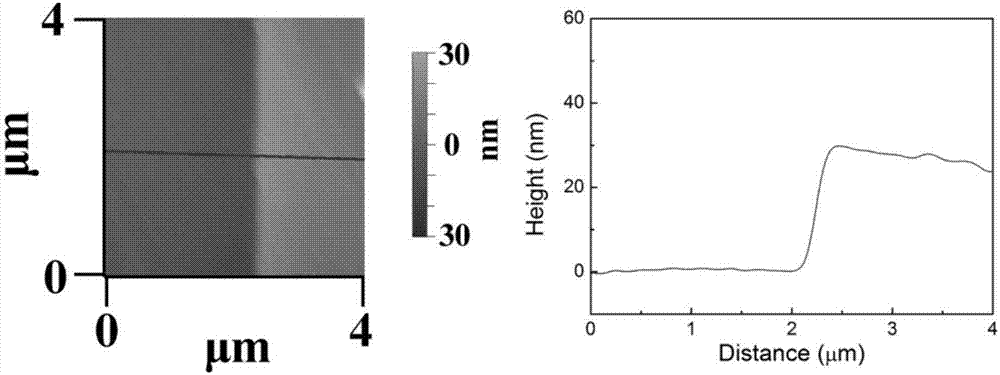

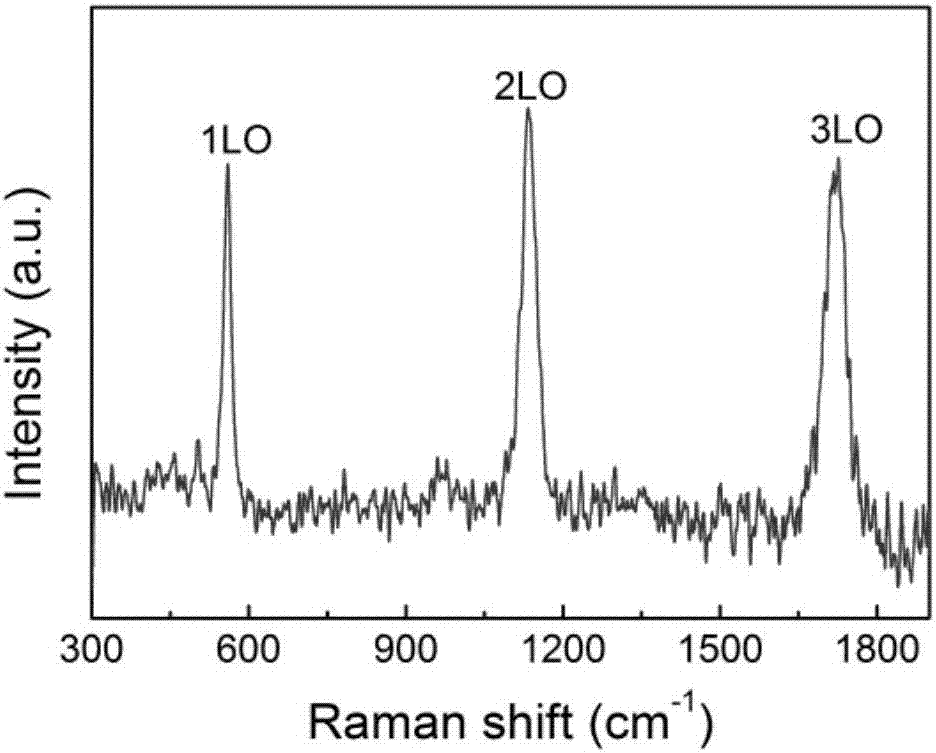

[0034] A method for preparing a two-dimensional ultra-thin structure single crystal ZnO nano-ultraviolet light detector, specifically comprising the following steps:

[0035] 1) A step of preparing two-dimensional ultra-thin structure single crystal ZnO nanomaterials by chemical vapor deposition method, and the surface is plated with polished SiO of 0.5~5 nm thick Au, Fe, Ni, Pt, Mo and other metals 2 Or sapphire as the substrate, ZnO or Zn powder with a purity of 99.9%, 100~800 mesh graphite powder with a purity of 99%, phosphorus, antimony, or vanadium oxide powder with a purity of 99% in a mass ratio of 1:0.1~ 5: 0.001~0.05 mixed, fed with oxygen and argon with a purity of 99.99%, and prepared by chemical deposition at 500~1200°C;

[0036] 2) Using methods such as ultrasonic dispersion, spin-coating organic films such as PMMA, PDMS, or PVDF on the two-dimensional ultra-thin structure single-crystal ZnO nanomaterial, or high-purity gas purging, the two-dimensional ultra-thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com