BGA package fixing structure of LED module

A technology of LED module and fixed structure, which is applied in the field of LED light sources, can solve the problems of unfavorable heat dissipation, aging of phosphor powder, and influence of heat dissipation, etc., and achieve the effect of reducing parasitic parameters, small signal transmission delay, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

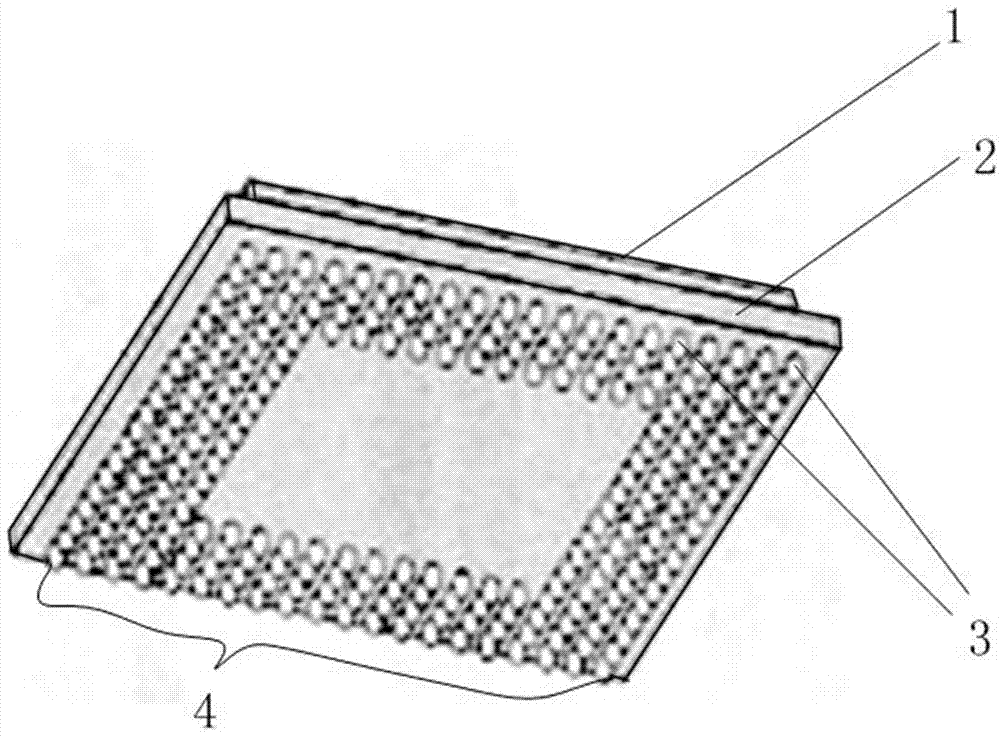

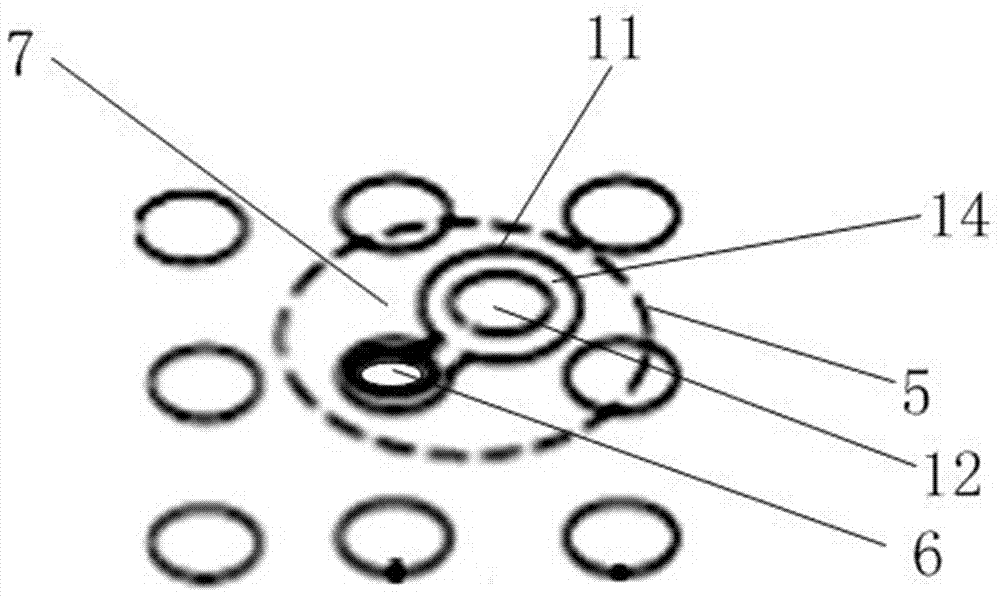

[0039] Such as Figure 1-5As shown, the LED module BGA package fixing structure, the BGA package fixing structure includes the LED module 9 in the BGA package form, the PCB board 10 and the BGA mounting and welding fixture; the LED module 9 is a light source device in the BGA package The LED module includes a BGA packaging substrate 2, an LSI chip 1, and a bump array 4; the bump array 4 is composed of a plurality of spherical or columnar solder joints 3 arranged in a predetermined arrangement on the soldering surface of the BGA packaging substrate 2 Composition; the bump array 4 is located on the back of the BGA packaging substrate 2; the LSI chip 1 is located on the front of the BGA packaging substrate 2; the LSI chip is provided with an LED light-emitting tube and supporting circuits that are packaged and fixed with molded or filled resin materials ; The electrical connection between the LSI chip and the bump array; the PCB board 10 is provided with a BGA light source pad 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com