Core-shell structure Pd-Sn@SiO2 catalyst and preparation method

A core-shell structure and catalyst technology, applied in the field of nano-catalyst preparation process and environmental protection, can solve the problems of poor thermal stability, deactivation of precious metals, etc., and achieve the effects of low equipment requirements, no secondary pollution, and solvent recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

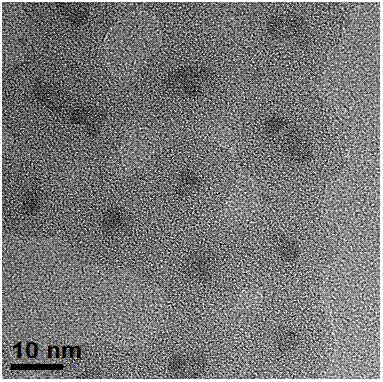

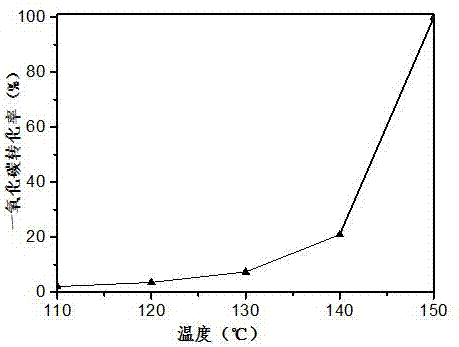

Embodiment 1

[0024] Weigh palladium nitrate tetraammonia and tin tetrachloride pentahydrate, dissolve them together in distilled water, and make Pd 2+ The solubility is 0.0583mol / L, Sn 4+ It is an aqueous solution with a solubility of 0.2612mol / L. Weigh 20.16g of polyethylene glycol mono-4-nonphenyl ether (n≈5) and dissolve it in cyclohexane, add 2.16ml of the above-mentioned nickel nitrate aqueous solution to the solution, and stir at 30°C for 15h. Then add 2.16ml of concentrated ammonia water with a mass fraction of 28%, continue stirring at 30°C for 2h, then add 2.5ml of tetraethyl orthosilicate, and continue stirring at 30°C for 48h. Add 16ml of ethanol to the resulting solution, then centrifuge at 10000rp / min for 15min to collect, and wash with cyclohexane three times. Vacuum drying at 40°C for 12h, proper grinding, and calcination at 600°C for 4h at a heating rate of 2°C / min in an air atmosphere to obtain Pd-Sn@SiO 2 Catalyst, wherein the massfraction of palladium is 2%, and the m...

Embodiment 2

[0027] Weigh palladium nitrate tetraammonia and tin tetrachloride pentahydrate, dissolve them together in distilled water, and make Pd 2+ The solubility is 0.0291mol / L, Sn 4+ It is an aqueous solution with a solubility of 0.2612mol / L. Weigh 20.16g of polyethylene glycol mono-4-nonphenyl ether (n≈5) and dissolve it in cyclohexane, add 2.16ml of the above-mentioned nickel nitrate aqueous solution to the solution, and stir at 30°C for 15h. Then add 2.16ml of concentrated ammonia water with a mass fraction of 28%, continue stirring at 30°C for 2h, then add 2.5ml of tetraethyl orthosilicate, and continue stirring at 30°C for 48h. Add 16ml of ethanol to the resulting solution, then centrifuge at 10000rp / min for 15min to collect, and wash with cyclohexane three times. Vacuum drying at 40°C for 12h, proper grinding, and calcination at 600°C for 4h at a heating rate of 2°C / min in an air atmosphere to obtain Pd-Sn@SiO 2 Catalyst, wherein the massfraction of palladium is 1%, and the m...

Embodiment 3

[0029] Weigh palladium nitrate tetraammonia and tin tetrachloride pentahydrate, dissolve them together in distilled water, and make Pd 2+ The solubility is 0.0583mol / L, Sn 4+ It is an aqueous solution with a solubility of 0.1306mol / L. Weigh 20.16g of polyethylene glycol mono-4-nonphenyl ether (n≈5) and dissolve it in cyclohexane, add 2.16ml of the above-mentioned nickel nitrate aqueous solution to the solution, and stir at 30°C for 15h. Then add 2.16ml of concentrated ammonia water with a mass fraction of 28%, continue stirring at 30°C for 2h, then add 2.5ml of tetraethyl orthosilicate, and continue stirring at 30°C for 48h. Add 16ml of ethanol to the resulting solution, then centrifuge at 10000rp / min for 15min to collect, and wash with cyclohexane three times. Vacuum drying at 40°C for 12h, proper grinding, and calcination at 600°C for 4h at a heating rate of 2°C / min in an air atmosphere to obtain Pd-Sn@SiO 2 Catalyst, wherein the massfraction of palladium is 2%, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com