A Micro-droplet Fusion Method Based on Hydrophilic Filament Induction

A technology of hydrophilic fiber filaments and fusion method, applied in the field of microfluidics, can solve the problems of influence and droplet stability, and achieve the effect of avoiding the production process and high-efficiency application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

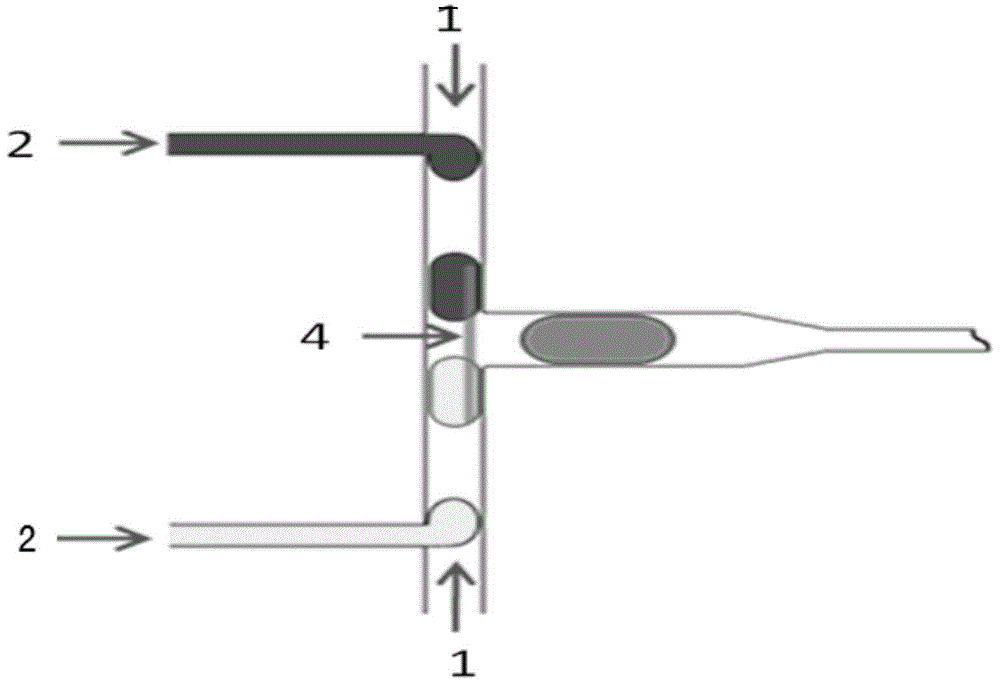

[0020] The fusion of microdroplets induced by hydrophilic filaments is realized on a microfluidic chip. The specific method is as follows: the production of the microfluidic chip is to use the photoetching technology to make the SU-8 template first, then pour polydimethylsiloxane on the template, polymerize in an oven at 80°C for 2 hours, and print the microstructure The polymer is peeled from the mold. Then, the hydrophilic glass filaments were embedded in the microchannel, and the flat polydimethylsiloxane sheet was treated with oxygen plasma and sealed together. Place the sealed chip in an oven at 80°C overnight to restore the hydrophobicity of the polydimethylsiloxane.

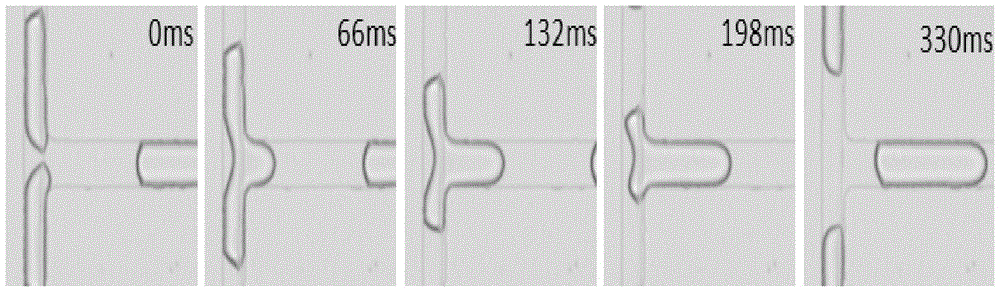

[0021] The design of the chip includes three T-shaped structures arranged in parallel (see figure 1 ). Surfactant (2.5% Span 80) was blended into the oil phase (mineral oil). Driven by the external pump, the oil phase flow rate is 0.1 μL / min, and the water phase (ultrapure water) flow rate is 0.1 μL / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com