Enhanced fully biodegradable material and preparation method thereof

A degradable material and all-biological technology, which is applied in the field of enhanced fully biodegradable materials and their preparation, can solve the problems of low tensile strength and elongation, and achieve high tensile strength and elongation, high elongation, and low The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

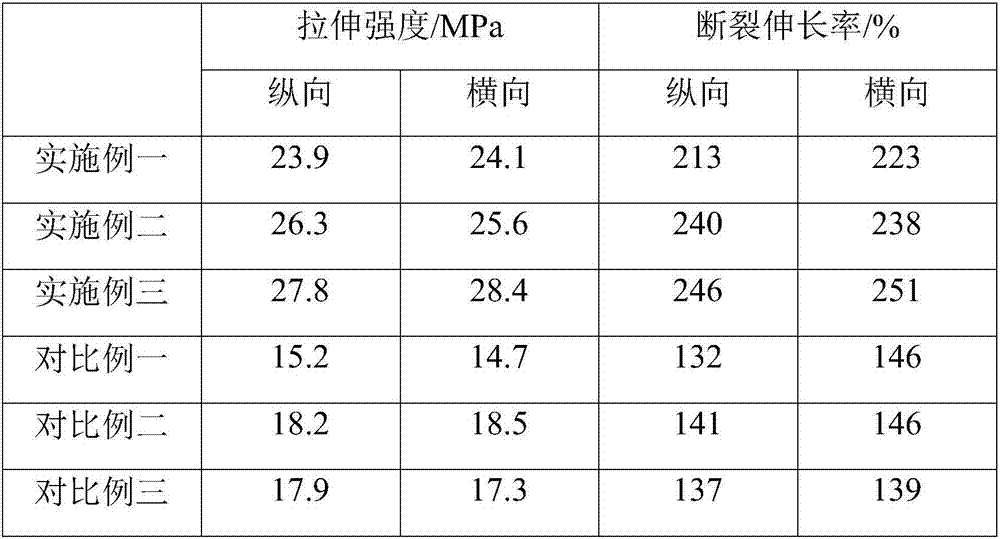

Examples

Embodiment 1

[0032] The invention provides a fully biodegradable material. The raw material components include 68.5 parts by weight of polybutylene adipate terephthalate, 29 parts by weight of polylactic acid 6201D, and hydroxylated carbon nanotubes with a length of 30 nm. 0.5 parts by weight, 1 part by weight of vinyltriethoxysilane, and 1 part by weight of isopropyltris(dioctylpyrophosphate acyloxy) titanate.

[0033] According to the above-mentioned raw material components, adopt the preparation method of the composite fully degradable material provided by the present invention to prepare the composite fully degradable material:

[0034] S101: Dry polybutylene adipate terephthalate and polylactic acid for 100 min under the conditions of a vacuum degree of 0.08 MPa and a temperature of 55° C.

[0035]S102: Combine hydroxylated carbon nanotubes, vinyl triethoxysilane, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate with dried polybutylene adipate terephthalate The mixing time is 1...

Embodiment 2

[0038] The invention provides a fully biodegradable material. The raw material components include 65 parts by weight of polybutylene adipate terephthalate, 27 parts by weight of polylactic acid 4032D, and hydroxylated carbon nanotubes with a length of 50 nm. 1 part by weight, 5 parts by weight of vinyl triethoxysilane, and 2 parts by weight of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate.

[0039] According to the above-mentioned raw material components, adopt the preparation method of the composite fully degradable material provided by the present invention to prepare the composite fully degradable material:

[0040] S101: Dry polybutylene adipate terephthalate and polylactic acid for 200 minutes under the conditions of a vacuum degree of 0.06 MPa and a temperature of 65° C.

[0041] S102: Combine hydroxylated carbon nanotubes, vinyl triethoxysilane, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate with dried polybutylene adipate terephthalate The mixing time...

Embodiment 3

[0044] The invention provides a fully biodegradable material. The raw material components include 65 parts by weight of polybutylene adipate terephthalate, 26 parts by weight of polylactic acid 3251D, and hydroxylated carbon nanotubes with a length of 40 nm. 1 part by weight, 5 parts by weight of vinyltriethoxysilane, and 3 parts by weight of isopropyltris(dioctylpyrophosphate acyloxy) titanate.

[0045] According to the above-mentioned raw material components, adopt the preparation method of the composite fully degradable material provided by the present invention to prepare the composite fully degradable material:

[0046] S101: Dry polybutylene adipate terephthalate and polylactic acid for 300 min under the conditions of a vacuum degree of 0.07 MPa and a temperature of 60° C.

[0047] S102: Combine hydroxylated carbon nanotubes, vinyl triethoxysilane, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate with dried polybutylene adipate terephthalate In a high-speed mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com