Antrodia camphorate growth promoter and method for fast producing antrodia camphorate through fermentation

A technology of growth promoter and fermentation method, which is applied in the field of rapid production of Antrodia camphorata mycelium and fruiting bodies, can solve the problems of high production cost, easy pollution of miscellaneous bacteria, and long cultivation period, so as to increase production cost and reduce pollution of miscellaneous substances. effect on the probability of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

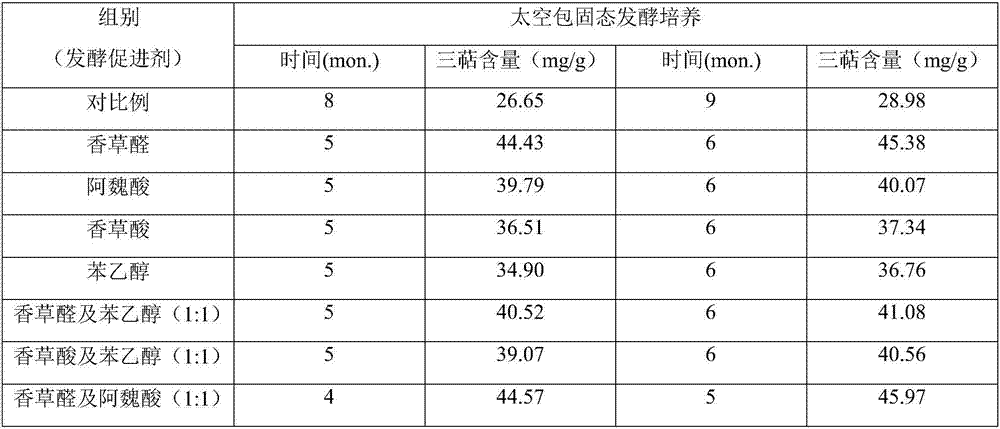

Examples

Embodiment 1

[0020] 1. Antrodia camphorata mycelium is transferred to PDA slant medium, cultured at 24-30°C for 10-20 days;

[0021] 2. Antrodia camphorata slant strains are inserted into the seed medium, and cultivated at 24-30°C for 10-20 days to obtain asexual spore-containing seed liquid;

[0022] Seed medium (g / L): glucose 15-25, yeast powder 0.5-2, magnesium sulfate 0.5-2, potassium dihydrogen phosphate 1-4, pH 4.5;

[0023] 3. The composition of Antrodia camphorata solid-state fermentation medium in terms of weight percentage is 30% to 60% of camphor wood chips, 5% to 20% of bran, 5% to 20% of bean cake powder, 0.15% to 3% of magnesium sulfate, and diphosphate Potassium hydrogen 0.15% to 3%, spray an aqueous solution containing 30 μM fermentation accelerator vanillin, adjust the water content to 35-65%, mix all materials to prepare space bags, each bag is 1.0 to 5.0 kg. Sterilize the space pack at 100-180°C for 2-5 hours, and cool to room temperature for later use.

[0024] 4. Ino...

Embodiment 2

[0027] 1. Antrodia camphorata mycelium is transferred to PDA slant medium, cultured at 24-30°C for 10-20 days;

[0028] 2. Antrodia camphorata slant strains are inserted into the seed medium, and cultivated at 24-30°C for 10-20 days to obtain asexual spore-containing seed liquid;

[0029] Seed medium (g / L): glucose 15-25, yeast powder 0.5-2, magnesium sulfate 0.5-2, potassium dihydrogen phosphate 1-4, pH 4.5;

[0030] 3. Antrodia camphorata liquid fermentation culture, the Antrodia camphorata seed liquid is inoculated in the Antrodia camphorata liquid fermentation medium (glucose 20g / L, yeast powder 2g / L, magnesium sulfate 1.5g / L, potassium dihydrogen phosphate 3.0% by volume ratio) g / L, pH 4.5), add 30 μM ferulic acid to the liquid fermentation medium of Antrodia camphorata, culture at 26°C and 150 rpm for 10 days, collect mycelia of Antrodia camphorata, dry and pulverize.

[0031] 4. Weigh 0.05g of Antrodia camphorata mycelium and sporocarp powder after drying and crushing,...

Embodiment 3

[0033] Adopt the method for cultivating the fruiting body of Antrodia camphorata without adding a fermentation accelerator, and the specific steps are as follows:

[0034] 1. Antrodia camphorata mycelium is transferred to PDA slant medium, cultured at 24-30°C for 10-20 days;

[0035] 2. Antrodia camphorata slant strains are inserted into the seed medium, and cultivated at 24-30°C for 10-20 days to obtain asexual spore-containing seed liquid;

[0036] Seed medium (g / L): glucose 15-25, yeast powder 0.5-2, magnesium sulfate 0.5-2, potassium dihydrogen phosphate 1-4, pH 4.5;

[0037] 3. The composition of Antrodia camphorata solid-state fermentation medium in terms of weight percentage is 30% to 60% of camphor wood chips, 5% to 20% of bran, 5% to 20% of bean cake powder, 0.15% to 3% of magnesium sulfate, diphosphate Potassium hydrogen 0.15% to 3%, adjust the water content to 35-65%, mix all materials to prepare space bags, each bag is 1.0 to 5.0kg. Sterilize the space pack at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com