Application of Bacillus megaterium to treatment of municipal sludge and method for producing biological organic fertilizer from Bacillus megaterium

A technology of Bacillus megaterium and municipal sludge, which is applied in the field of bio-organic fertilizer production, can solve the problems of late start, difficulty in finding sludge disposal methods for treatment plants, sludge disposal sites, and low bacterial survival rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

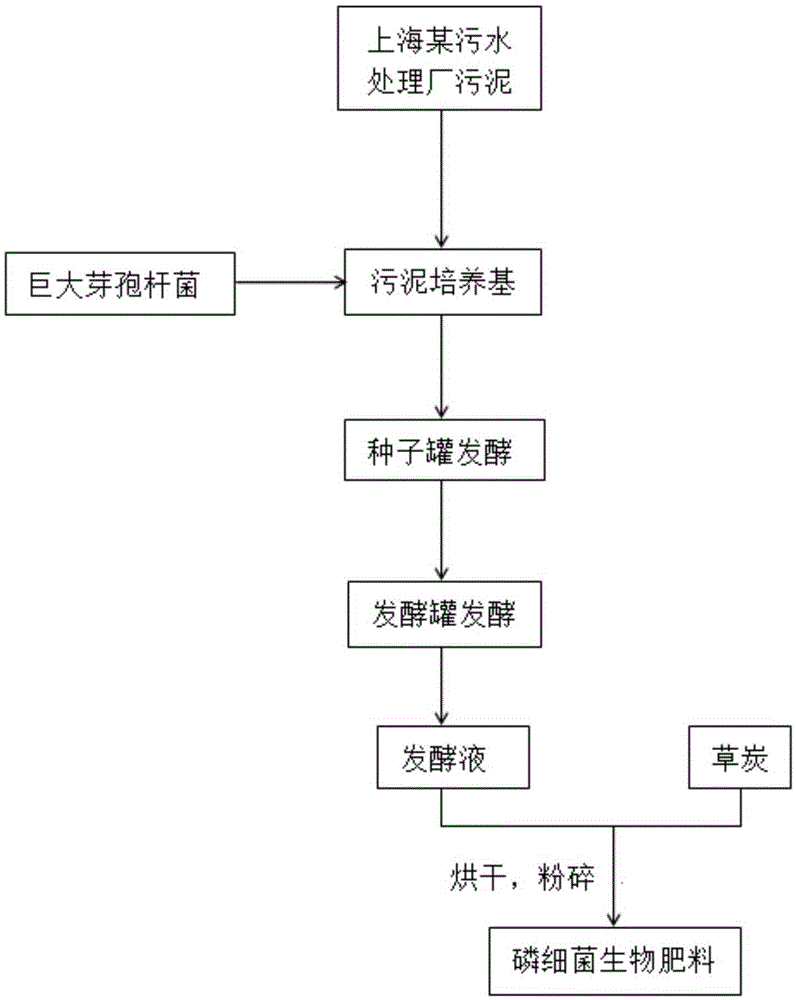

[0032] Embodiment 1 handles the method for municipal sludge

[0033] The concrete steps of the method that Bacillus megaterium of the present invention is used for processing municipal sludge are as follows:

[0034] (1) Pre-treatment of sludge samples:

[0035] Take municipal sludge and use tap water to adjust the solid content of the sludge to 1%, add defoamer, the amount of defoamer added is 3g / L, adjust the pH of the sludge sample to 7-8, and test in the seed tank and fermentation tank respectively Sterilize at 0.1MPa pressure and 121°C for 45 minutes, cool to 30°C for later use;

[0036] (2) Bacillus megaterium shake flask culture:

[0037] Inoculate Bacillus megaterium into a Erlenmeyer flask equipped with fermentation medium according to the inoculation amount of 5%, and carry out shake flask culture. The culture conditions are: temperature 25°C, rotation speed 300r / min, culture time 10 hours;

[0038] (3) Seed tank fermentation and fermenter fermentation:

[0039]I...

Embodiment 2

[0043] Embodiment 2 handles the method for municipal sludge

[0044] The concrete steps of the method that Bacillus megaterium of the present invention is used for processing municipal sludge are as follows:

[0045] (1) Pre-treatment of sludge samples:

[0046] Take municipal sludge and use tap water to adjust the solid content of the sludge to 5%, add defoamer, the amount of defoamer added is 1g / L, adjust the pH of the sludge sample to 7-8, and test in the seed tank and fermentation tank respectively Sterilize at 0.1MPa pressure and 121°C for 60 minutes, cool to 30°C for later use;

[0047] (2) Bacillus megaterium shake flask culture:

[0048] Inoculate Bacillus megaterium into a Erlenmeyer flask equipped with fermentation medium according to the inoculation amount of 1%, and carry out shake flask culture. The culture conditions are: temperature 35°C, rotation speed 200r / min, culture time 20 hours;

[0049] (3) Seed tank fermentation and fermenter fermentation:

[0050] ...

Embodiment 3

[0054] Embodiment 3 handles the method for municipal sludge

[0055] (1) Pre-treatment of sludge samples

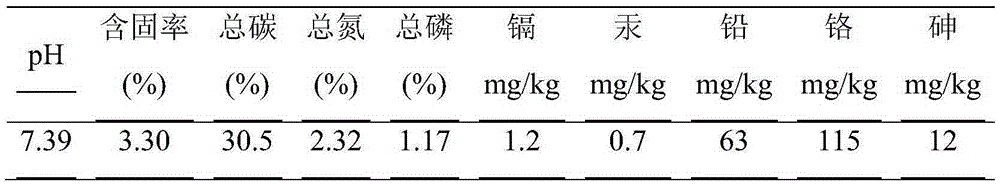

[0056] Sludge from a sewage treatment plant in Shanghai was randomly sampled to determine the basic physical and chemical properties of the sludge. The results are shown in Table 1.

[0057] Table 1 Physical and chemical properties of sludge

[0058]

[0059] Use tap water to adjust the solid content of the sludge to 3.0%, add defoamer, the amount of defoamer added is 2.0g / L, adjust the pH of the sludge sample to about 7.0-8.0, and pass 0.1MPa in the seed tank and fermentation tank respectively. Sterilize under pressure and temperature of 121°C for 45-60 minutes, cool to 30°C for later use, and the pH of the sludge sample after sterilization is about 7.0-8.0.

[0060] (2) Bacillus megaterium shake flask culture

[0061] The Bacillus megaterium was inoculated into multiple Erlenmeyer flasks containing fermentation medium according to the inoculum amount of 3%, and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com