Modified titanium dioxide photoelectrode and preparation method and application thereof

A titanium dioxide and photoelectrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of limited types of co-catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

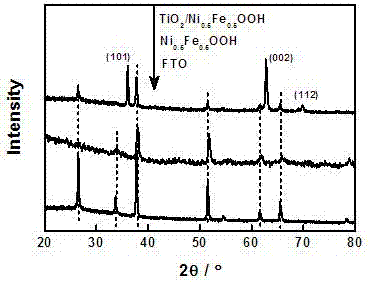

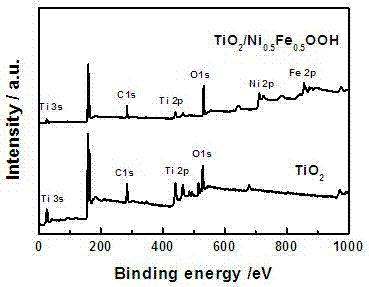

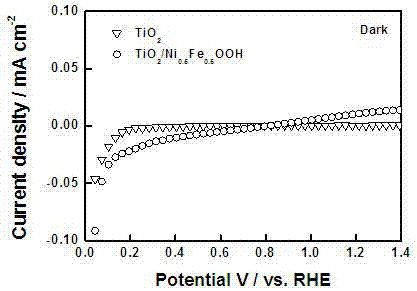

[0024] A kind of Ni 1-x Fe x The preparation method of OOH modified titanium dioxide photoelectrode comprises the following steps:

[0025] (1) Add 0.42mL isopropyl titanate to 18mL 6mol / L hydrochloric acid, stir at room temperature for 10 minutes to obtain a mixed solution;

[0026] (2) Pour the mixed solution obtained in step (1) into a 25mL reaction kettle, and insert the FTO conductive glass. The upper end of the FTO conductive glass is higher than the liquid level of the mixed solution, so that a certain blank area is left above the FTO conductive glass as an electrode. Clamp the fixed area; put the reaction kettle in an oven, react with water heat at 150°C for 6 hours, and cool to room temperature naturally; then take out the conductive glass, wash it with high-purity water, and dry it with nitrogen to obtain a FTO conductive glass covered with a milky white film. Glass; then put the FTO conductive glass covered with a milky white film in a muffle furnace, heat up to 4...

Embodiment 2

[0029] A kind of Ni 1-x Fe x The preparation method of OOH modified titanium dioxide photoelectrode comprises the following steps:

[0030] (1) Add 0.42mL isopropyl titanate to 18mL 6mol / L hydrochloric acid, stir at room temperature for 10 minutes to obtain a mixed solution;

[0031] (2) Pour the mixed solution obtained in step (1) into a 25mL reaction kettle, and insert the FTO conductive glass. The upper end of the FTO conductive glass is higher than the liquid level of the mixed solution, so that a certain blank area is left above the FTO conductive glass as an electrode. Clamp the fixed area; put the reaction kettle in an oven, react with water heat at 150°C for 6 hours, and cool to room temperature naturally; then take out the conductive glass, wash it with high-purity water, and dry it with nitrogen to obtain a FTO conductive glass covered with a milky white film. Glass; then put the FTO conductive glass covered with a milky white film in a muffle furnace, heat up to 4...

Embodiment 3

[0034] A kind of Ni 1-x Fe x The preparation method of OOH modified titanium dioxide photoelectrode comprises the following steps:

[0035] (1) Add 0.42mL isopropyl titanate to 18mL 6mol / L hydrochloric acid, stir at room temperature for 10 minutes to obtain a mixed solution;

[0036] (2) Pour the mixed solution obtained in step (1) into a 25mL reaction kettle, and insert the FTO conductive glass. The upper end of the FTO conductive glass is higher than the liquid level of the mixed solution, so that a certain blank area is left above the FTO conductive glass as an electrode. Clamp the fixed area; put the reaction kettle in an oven, react with water heat at 150°C for 6 hours, and cool to room temperature naturally; then take out the conductive glass, wash it with high-purity water, and dry it with nitrogen to obtain a FTO conductive glass covered with a milky white film. Glass; then put the FTO conductive glass covered with a milky white film in a muffle furnace, heat up to 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com