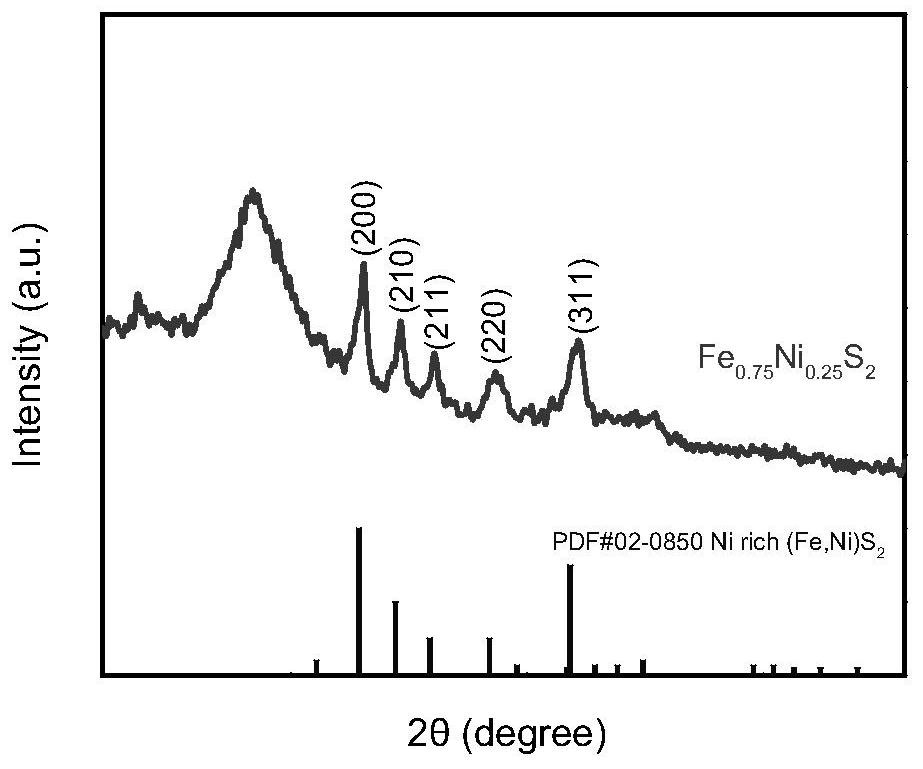

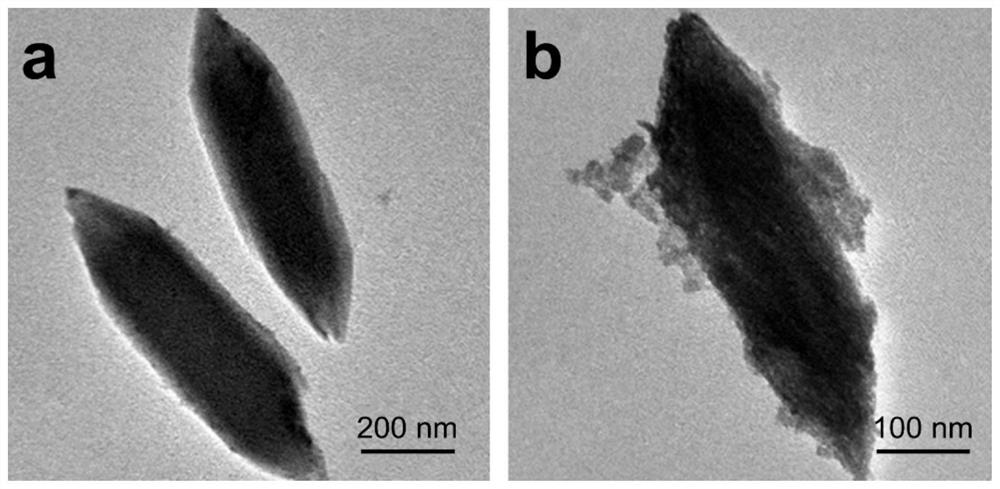

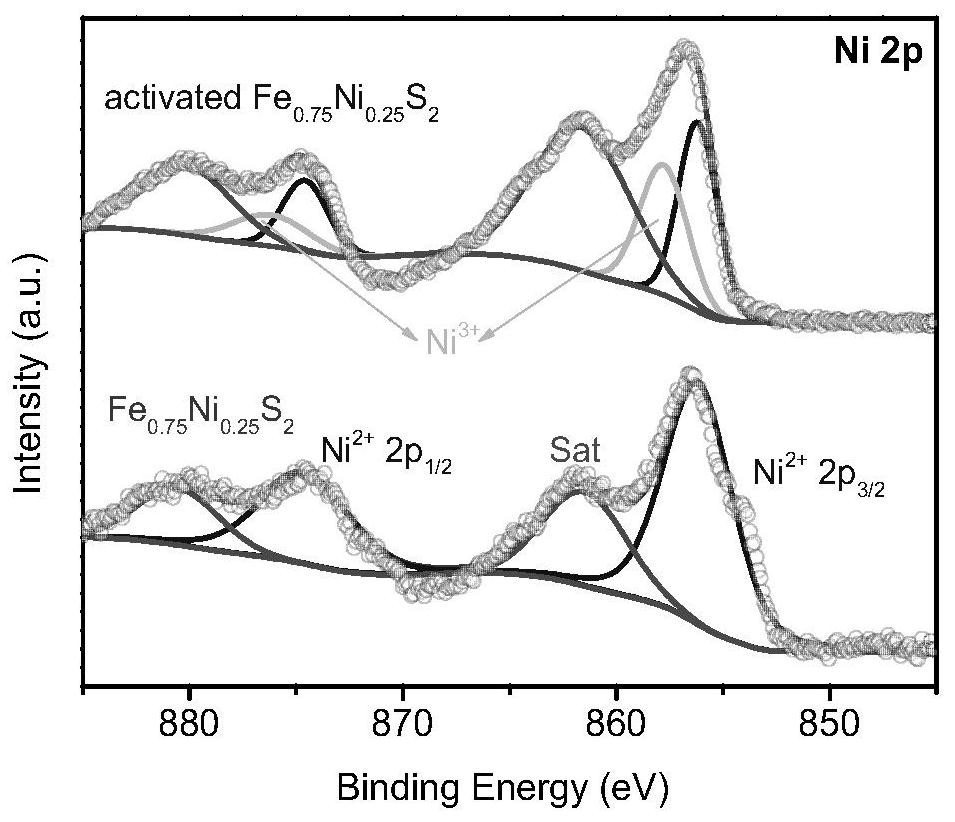

Metal-organic framework-derived iron-nickel metal sulfide catalysts and their preparation and application

A metal sulfide and catalyst technology, applied in the field of renewable energy catalytic materials, can solve the problems of cumbersome preparation process, high cost, poor performance, etc., and achieve the effects of simple preparation process, improved oxygen evolution reaction activity, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve 0.811g ferric chloride hexahydrate, 0.872g nickel nitrate hexahydrate and 0.997g terephthalic acid in 60mL of N,N-dimethylformamide and stir for 30min to form a uniform solution;

[0046] (2) Measure 12 mL of sodium hydroxide solution and add it to the solution obtained in step (1) and stir for 3 hours until uniform, and the concentration of the sodium hydroxide solution is 16 g / L;

[0047] (3) Transfer the mixed solution in step (2) to a reactor for solvothermal, the reaction temperature is 100°C, and the reaction time is 15h;

[0048] (4) Centrifugally wash the mixed solution in step (3) (washing with water, washing with alcohol), and then dry overnight in an oven at 70°C;

[0049] (5) Grinding the solid obtained in step (4) to obtain the precursor MIL-88;

[0050] (6) After weighing 0.450g of thioacetamide and adding 60mL of ethanol to dissolve to form a uniform solution, add 0.1g of precursor MIL-88 and fully stir for 30min;

[0051] (7) Transfer the ...

Embodiment 2

[0062] Similar to Example 1, the difference is that the secondary solvothermal reaction temperature in the (7) step is changed from 120°C to 100°C, and the reaction time is changed to 6h, and the other steps are carried out using the method of Example 1 to obtain the present invention. said catalyst.

Embodiment 3

[0064] Similar to Example 1, the difference is that the second solvothermal reaction time in the (7) step is changed to 6h, and other steps are carried out by the method of Example 1 to obtain the catalyst of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com