Tungsten trioxide composite photoelectrode, preparation method thereof, and application in photoelectrocatalytic water splitting

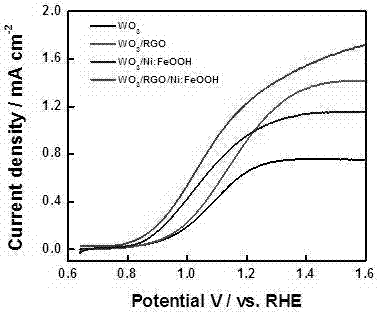

A technology of tungsten trioxide and composite light, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., to achieve the effects of improving transfer efficiency, promoting oxygen evolution reaction, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

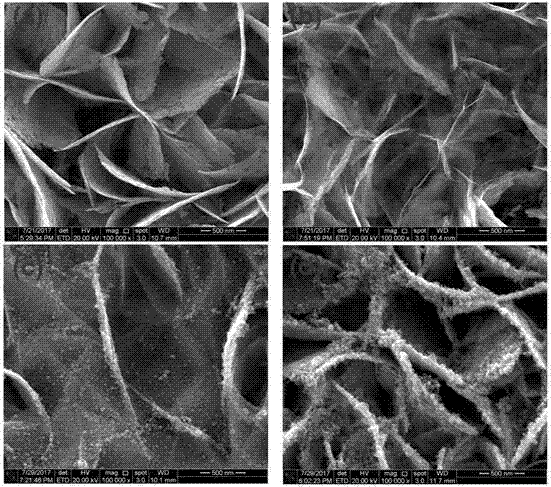

[0032] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0033] (1) Add 0.625g tungstic acid and 0.25g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After ultrasonication of the ionized water for 15 minutes, dry it with nitrogen gas; then place the FTO conductive glass on the rotating disk of the spin coater, pipette 150 μL of the seed layer solution and drop-coat it on the conductive glass, and the coating area is fixed as 1.5cm 2 , the rotation speed is 3000 rpm, and it is maintained for 30 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 5 times. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On a temperature-controlled titanium substrate heating platform, raise the tempera...

Embodiment 2

[0038] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0039] (1) Add 0.595g tungstic acid and 0.17g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After ultrasonication of the ionized water for 15 minutes, dry it with nitrogen gas; then place the FTO conductive glass on the rotating disk of the spin coater, pipette 120 μL of the seed layer solution and drop-coat it on the conductive glass with a fixed coating area of 1.5cm 2 , the rotating speed is 3500 rpm, and it is maintained for 20 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 20 times in total. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On the temperature-controlled titanium substrate heating platform, the temper...

Embodiment 3

[0044] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0045] (1) Add 0.68g tungstic acid and 0.34g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After the ionized water was ultrasonicated for 15 minutes, it was blown dry with nitrogen; then the FTO conductive glass was placed on the rotating disk of the spin coater, and 180 μL of the seed layer solution was pipetted with a pipette gun and drip-coated on the conductive glass, and the coating area was fixed as 1.5cm 2 , the rotating speed is 2500 rpm, and it is maintained for 40 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 10 times in total. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On the temperature-controlled tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com