porous carbon-fe 3 o 4 Nanomaterials, air cathode materials and lithium-air batteries

A nanomaterial, air cathode technology, applied in the field of electrochemical energy, can solve the problems of low Coulombic efficiency, low rate performance, short cycle life, etc., and achieve the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

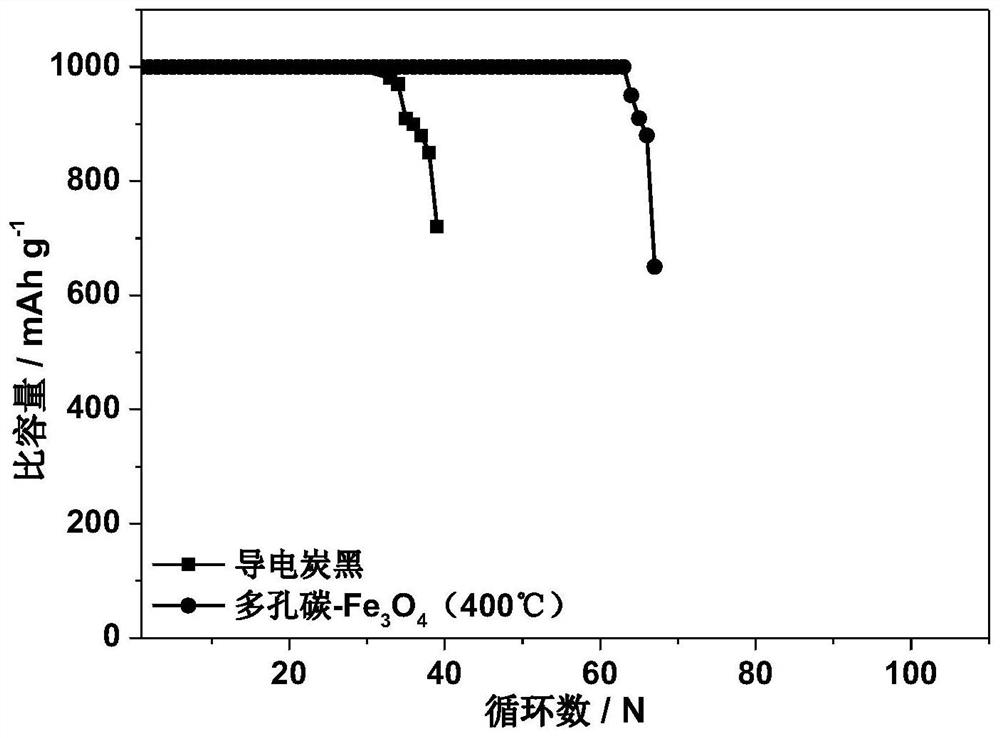

Embodiment 1

[0052] Weigh Fe(NO 3 ) 3 9H 2 O and aspartic acid are dissolved or dispersed in NaOH deionized aqueous solution to obtain mixed solution a, wherein the concentration of ferric nitrate in mixed solution a is 1 mmol / L, the concentration of aspartic acid is 1 mmol / L, and NaOH The concentration is 0.1mol / L, and then the mixed solution a is put into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, reacted at 130°C to 180°C for 2h, and then cooled at room temperature to obtain a solution with a yellow precipitate, which was Centrifuge at 6000rpm for 5min to obtain a yellow precipitate, dissolve the yellow precipitate in water and let it stand, dissolve the excess organic solvent in water, then centrifuge, and vacuum dry at 80°C to remove excess water and excess organic solvent to obtain the precursor MOF material, and then put the obtained precursor MOF material into a porcelain boat, and then calcined at a temperature of 400 °C for 2 h at a heating rate...

Embodiment 2

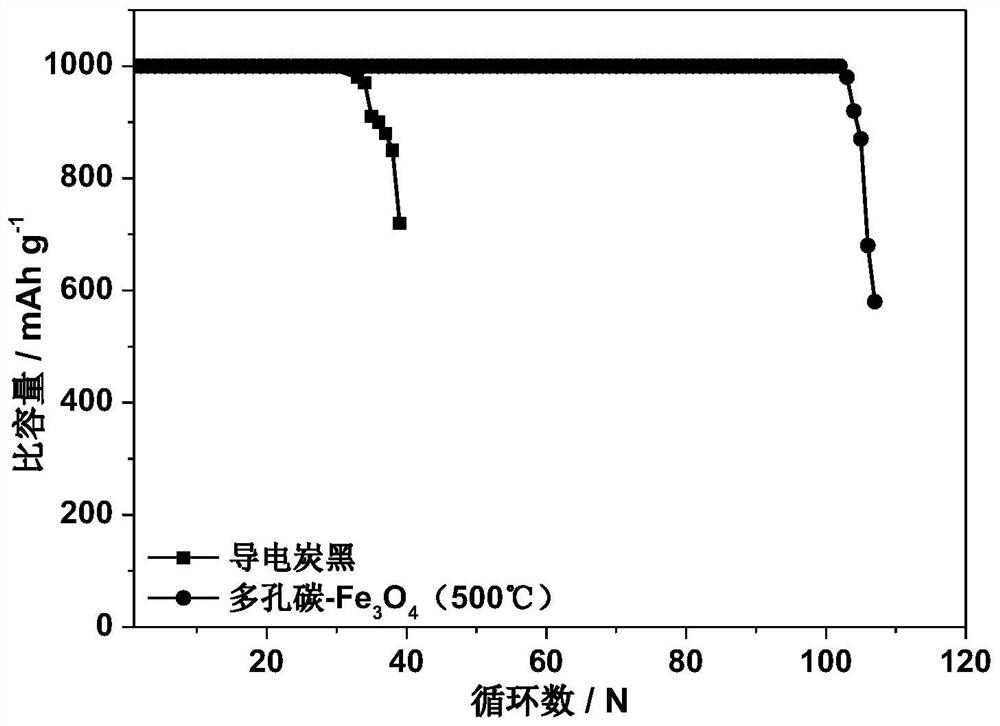

[0056] Weigh Fe(NO 3 ) 3 9H 2 O and aspartic acid, and dissolve or disperse in NaOH deionized aqueous solution, obtain mixed solution a, wherein, the concentration of ferric nitrate in mixed solution a is 1 mmol / L, and the concentration of aspartic acid is 2mmol / L, The concentration of NaOH is 0.1mol / L, and then the mixed solution a is loaded into a stainless steel reactor with a polytetrafluoroethylene substrate, reacted at 150°C for 2h, and then cooled at room temperature to obtain a solution with a yellow precipitate, which was heated at 6000rpm Centrifuge for 5 minutes to obtain a yellow precipitate, dissolve the yellow precipitate in water and let it stand, dissolve the excess organic solvent in water, then centrifuge, vacuum dry at 80°C to remove excess water and excess organic solvent, and obtain the precursor MOF material, Then put the obtained precursor MOF material into a porcelain boat, and then calcined at a temperature of 500 °C for 2 h at a heating rate of 5 °C...

Embodiment 3

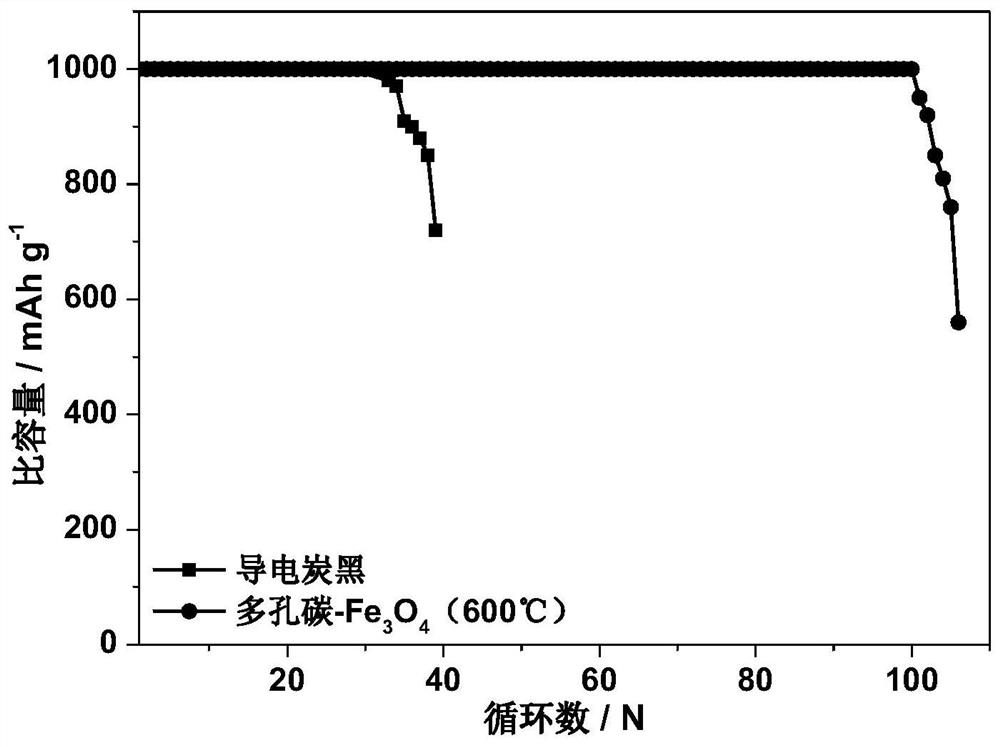

[0060] According to the molar ratio of 1:3, Fe(NO 3 ) 3 9H 2 O and aspartic acid, and dissolve or disperse in the deionized aqueous solution of NaOH, obtain mixed solution a, wherein, the concentration of ferric nitrate in mixed solution a is 1mmol / L, and the concentration of aspartic acid is 3mmol / L, The concentration of NaOH is 0.1mol / L, and then the mixed solution a is loaded into a stainless steel reactor with a polytetrafluoroethylene substrate, reacted at 150°C for 2h, and then cooled at room temperature to obtain a solution with a yellow precipitate, which was heated at 6000rpm Centrifuge for 5 minutes to obtain a yellow precipitate, dissolve the yellow precipitate in water and let it stand, dissolve the excess organic solvent in water, then centrifuge, vacuum dry at 80°C to remove excess water and excess organic solvent, and obtain the precursor MOF material, Then put the obtained precursor MOF material into a porcelain boat, and then calcined at a temperature of 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com