Method for preparing self-supporting nickel-cobalt-iron hydrotalcite-based catalyst through one-step wet etching

A self-supporting, catalyst technology, used in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of high cost and scarcity of precious metal-based catalysts, restrict development and application, etc., and achieve rapid electron transfer, low cost, and oxygen evolution effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

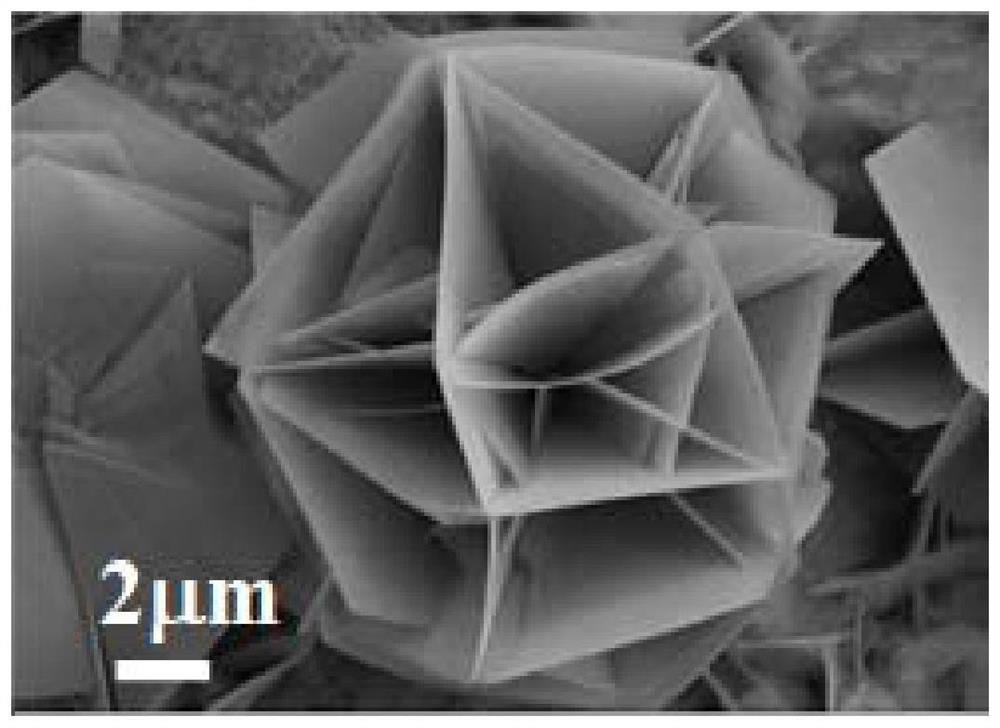

Embodiment 1

[0041] Step (1): Foam nickel pretreatment

[0042]Nickel foam (2×5 cm) was sonicated with acetone, hydrochloric acid, ethanol and deionized water for 20 minutes to remove impurities.

[0043] Step (2): Precursor preparation

[0044] At room temperature, 1.8mmol (0.5220g) of Co(NO 3 ) 2 ·6H 2 O and 0.2mmol (0.0808g) of Fe(NO 3 ) 3 9H 2 O and 10mmol (0.37g) of NH 4 F, 10mmol (0.6006g) of CO (NO 2 ) 2 Dissolve in 50ml deionized water and stir for 10 minutes to obtain a precursor solution.

[0045] Step (3): Hydrothermal reaction

[0046] The precursor solution in step (2) is transferred in the stainless steel autoclave of liner polytetrafluoroethylene of 100ml, the foamed nickel processed in step (1) is put into the precursor solution and sealed stainless steel autoclave, it is Put it into an oven and react at 95°C for 8 hours.

[0047] Step (4): Wash and dry

[0048] After the hydrothermal reaction in step (3) is completed, the nickel foam is taken out, rinsed with ...

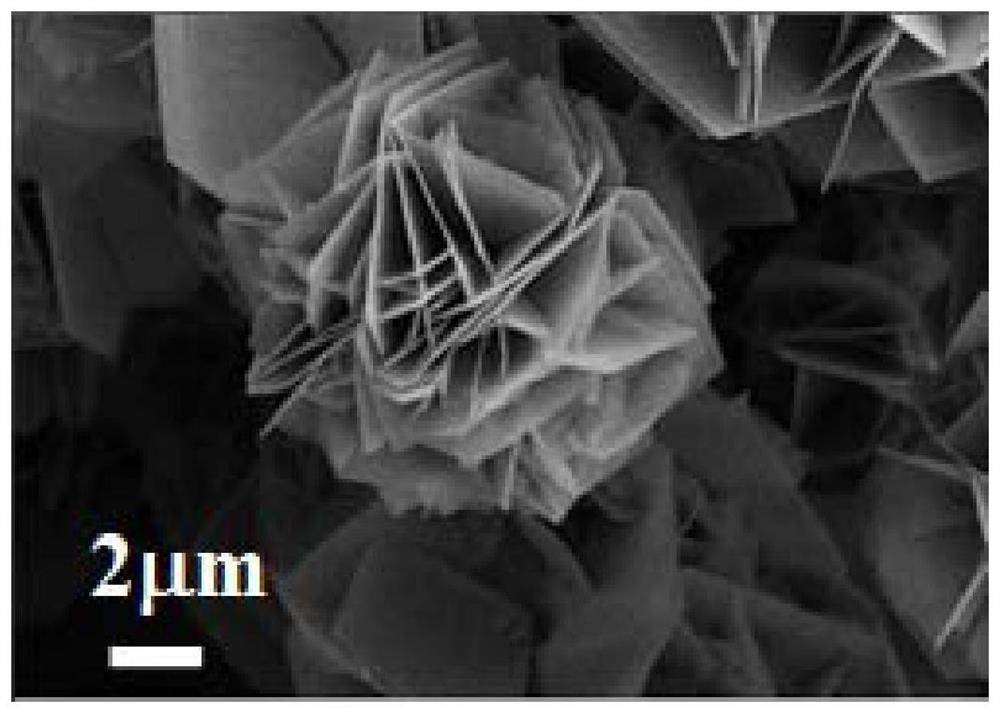

Embodiment 2

[0053] Step (1): Foam nickel pretreatment

[0054] Nickel foam (2×5 cm) was sonicated with acetone, hydrochloric acid, ethanol and deionized water for 20 minutes to remove impurities.

[0055] Step (2): Precursor preparation

[0056] At room temperature, 1.0mmol (0.2910g) of Co(NO 3 ) 2 ·6H 2 O and 1.0mmol (0.4040g) of Fe(NO 3 ) 3 9H 2 O and 10mmol (0.37g) of NH 4 F, 10mmol (0.6006g) of CO (NO 2 ) 2 Dissolve in 50ml deionized water and stir for 10 minutes to obtain a precursor solution.

[0057] Step (3): Hydrothermal reaction

[0058] The solution in the step (2) is transferred to a stainless steel autoclave lined with polytetrafluoroethylene in 100ml, the nickel foam processed in the step (1) is put into the precursor solution, and the stainless steel autoclave is sealed, and it is placed Put it into an oven and react at a temperature of 95°C for 8 hours.

[0059] Step (4): Wash and dry

[0060] After the reaction of step (3) is completed, the nickel foam is tak...

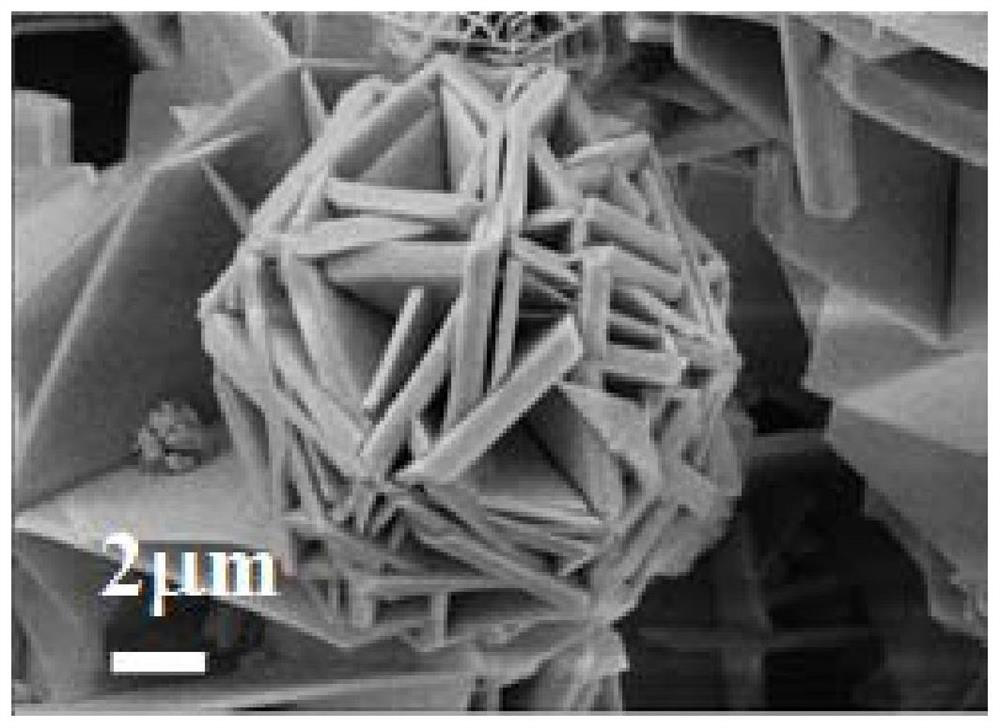

Embodiment 3

[0065] Step (1): Foam nickel pretreatment

[0066] Nickel foam (2×5 cm) was sonicated with acetone, hydrochloric acid, ethanol and deionized water for 20 minutes to remove impurities.

[0067] Step (2): Precursor preparation

[0068] At room temperature, 0.2mmol (0.0580g) of Co(NO 3 ) 2 ·6H 2 O and 1.8mmol (0.7272g) of Fe(NO 3 ) 3 9H 2 O and 10mmol (0.37g) of NH 4 F, 10mmol (0.6006g) of CO (NO 2 ) 2 Dissolve in 50ml deionized water and stir for 10 minutes to obtain a precursor solution.

[0069] Step (3): Hydrothermal reaction

[0070] Transfer the solution in step (3) to a 100ml polytetrafluoroethylene autoclave, put the nickel foam treated in step (1) into the solution and seal the autoclave, put it into an oven and react at 95°C 8 hours.

[0071] Step (4): Wash and dry

[0072] After the hydrothermal reaction of step (3) is completed, the nickel foam is taken out, rinsed several times with deionized water, and then dried at 60° for 6 hours to obtain Ni x co 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com