Preparation method of Co2P/CuP2/NF hydrogen and oxygen evolution electrocatalyst

An electrocatalyst and oxygen evolution technology, applied in electrodes, electrolysis components, electrolysis process, etc., to achieve excellent electrocatalytic hydrogen evolution and oxygen evolution performance, simple preparation method and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

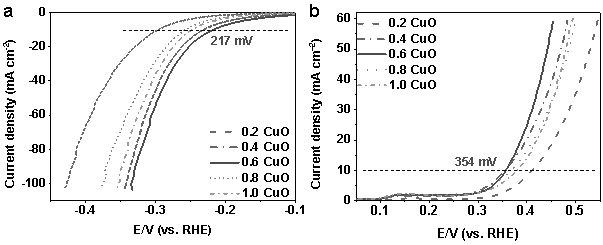

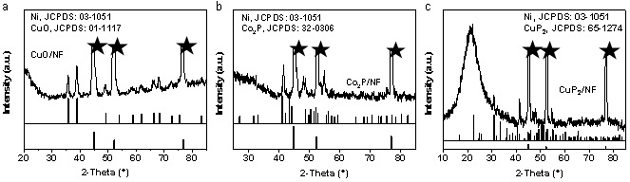

[0026] Two, embodiment 1: prepare CuO / NF material

[0027] Step (1) Process nickel foam: cut nickel foam into 3×1.5 cm 2 size. Then ultrasonically wash in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 10 minutes respectively, cycle wash three times, and dry naturally for later use.

[0028] Step (2) Prepare copper chloride dihydrate solution: weigh 0.6 mmol (0.2, 0.4, 0.8, 1.0 mmol) copper chloride dihydrate and dissolve it in 15 mL deionized water, sonicate for 10 minutes to obtain a copper chloride solution, then add 750 uL ammonia solution was sonicated for 10 minutes.

[0029] Step (3) Low-temperature hydrothermal reaction: put the nickel foam washed in step (1) into a small glass bottle containing 20 mL of the solution prepared in step (2), and keep it warm in an oven at 80°C 2 hours. After natural cooling, rinse the nickel foam with plenty of water, and then dry it at room temperature for later use.

Embodiment 2

[0030] Three, embodiment 2: prepare CuP 2 / NF material

[0031] Step (1) process nickel foam: cut the nickel foam into 3×1.5 cm 2 size. Then ultrasonically wash in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 10 minutes respectively, cycle wash three times, and dry naturally for later use.

[0032] Step (2) Prepare copper chloride dihydrate solution: Weigh 0.8 mmol copper chloride dihydrate and dissolve it in 15 mL deionized water, sonicate for 10 minutes to obtain a copper chloride solution, then add 750 uL ammonia water for 10 minutes to sonicate to adjust the solution pH value.

[0033] Step (3) Low-temperature hydrothermal reaction: put the nickel foam washed in step (1) into a small glass bottle containing 20 mL of the solution prepared in step (2), and keep it warm in an oven at 80°C 2 hours. After natural cooling, rinse the nickel foam with plenty of water, and then dry it at room temperature for later use.

[0034] Step (4) Low-temperature ph...

Embodiment 3

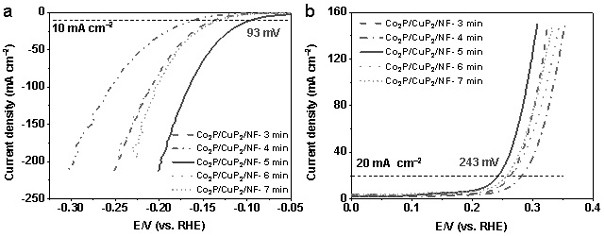

[0035] Four, embodiment 3: preparation Co 2 P / NF material

[0036] Step (1) process nickel foam: cut the nickel foam into 1×1.5 cm 2 size. Then ultrasonically wash in 0.5 mol / L sulfuric acid solution, deionized water and ethanol for 10 minutes respectively, cycle wash three times, and dry naturally for later use.

[0037] Step (2) Prepare the cobalt nitrate solution: weigh 0.29 g of cobalt nitrate hexahydrate and dissolve it in 25 mL of deionized water, and sonicate for 10 minutes to obtain the cobalt nitrate solution.

[0038] Step (3) Constant potential electrodeposition: In the three-electrode system, nickel foam is used as the working electrode, the platinum sheet is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the electrolyte is the cobalt nitrate solution prepared in step (2) , electrodeposited at a constant potential of -1.1 V for 5 min. After natural cooling, the nickel foam was rinsed with deionized water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com