Dealcoholized condensed dual-component room-temperature vulcanized silicone rubber building sealant and preparation method thereof

A room temperature vulcanization, dealcohol condensation technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc. Good operation stability, good water-resistant immersion bonding performance, and the effect of improving hot-water-resistant bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

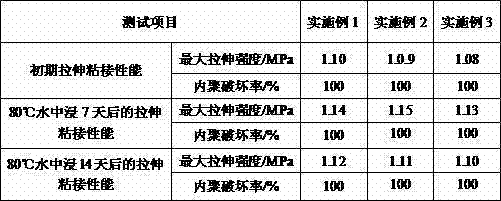

Examples

Embodiment 1

[0030] A kind of preparation method of dealcohol condensation type two-component room temperature vulcanized silicone rubber building sealant, its preparation method is as follows:

[0031] (1) 40 parts of 80000 mPa.s α, ω-dihydroxy polydimethylsiloxane, 60 parts of 20000 mPa.s α, ω-dihydroxy polydimethylsiloxane, 100 parts by mass Add 25 parts of mPa.s simethicone oil and 80 parts of calcium carbonate into a high-speed planetary mixer, and stir for 2.5 hours under a vacuum of -0.05MPa to prepare component A;

[0032] (2) In parts by mass, 100 parts of 100 mPa.s dimethyl silicone oil, 50 parts of ethyl orthosilicate, 25 parts of propyl orthosilicate, γ-(2,3-epoxypropoxy)propane Add 15 parts of trimethoxysiloxane, 18 parts of γ-aminopropyltriethoxysilane, and 1.5 parts of dibutyltin dilaurate into a high-speed planetary mixer, and stir for 2 hours under a vacuum of -0.05MPa. Component B is obtained;

[0033] (3) Mix component A and component B uniformly at a mass ratio of 10:...

Embodiment 2

[0035] A kind of preparation method of dealcohol condensation type two-component room temperature vulcanized silicone rubber building sealant, its preparation method is as follows:

[0036] (1) Add 80 parts by mass of 80000 mPa.s α, ω-dihydroxypolydimethylsiloxane, 30 parts of methylphenyl silicone oil and 60 parts of quartz powder into a high-speed planetary mixer, Under -0.1MPa, stir for 2.5h to obtain component A;

[0037] (2) In parts by mass, 80 parts of simethicone, 50 parts of propyl orthosilicate, 10 parts of polyethyl silicate, 15 parts of γ-aminopropyltriethoxysilane and isopropyl titanate Add 0.5 parts into a high-speed planetary mixer, and stir for 2 hours under a vacuum of -0.05MPa to prepare component B;

[0038] (3) Mix component A and component B uniformly at a mass ratio of 25:2.

Embodiment 3

[0040] A kind of preparation method of dealcohol condensation type two-component room temperature vulcanized silicone rubber building sealant, its preparation method is as follows:

[0041] (1) Add 60 parts of 80000 mPa.s α, ω-dihydroxypolydimethylsiloxane, 10 parts of dimethyl silicone oil, 20 parts of methylphenyl silicone oil and 80 parts of diatomaceous earth in parts by mass In a high-speed planetary mixer, under a vacuum of -0.05MPa, stir for 2 hours to prepare component A;

[0042] (2) In parts by mass, 70 parts of simethicone, 50 parts of ethyl orthosilicate, 25 parts of propyl orthosilicate, N-(β-aminoethyl)-γ-aminopropyltrimethoxy Add 20 parts of silane and 0.1 part of dibutyltin diacetate into a high-speed planetary mixer, and stir for 2.5 hours under a vacuum of -0.06MPa to prepare component B;

[0043] (3) Mix component A and component B uniformly at a mass ratio of 100:9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com