Alginate-based-polycationic microcapsule and applications thereof in embedding bioactive substance

A bioactive substance, alginate technology, applied in the field of alginate microcapsule products, can solve the problems of inappropriate active substance embedding, long time-consuming, complicated microcapsule preparation methods, etc. Gentle and controllable, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

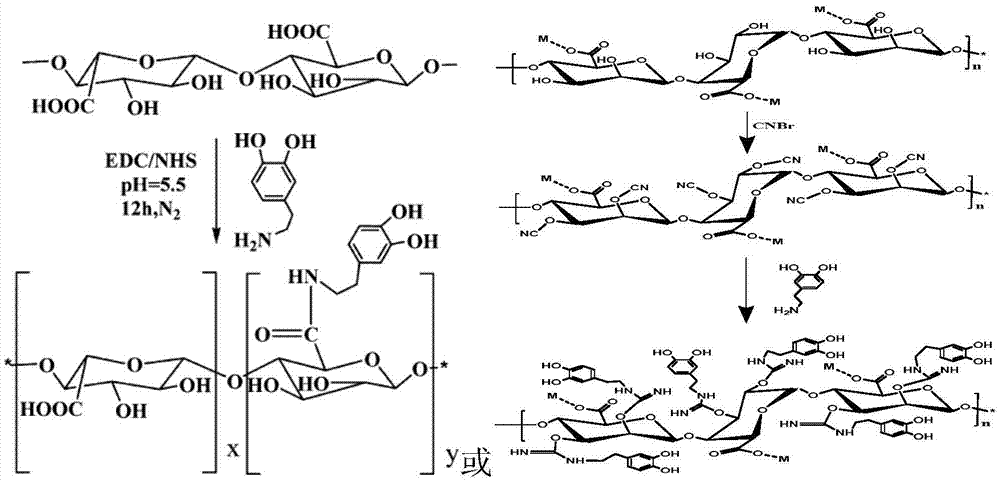

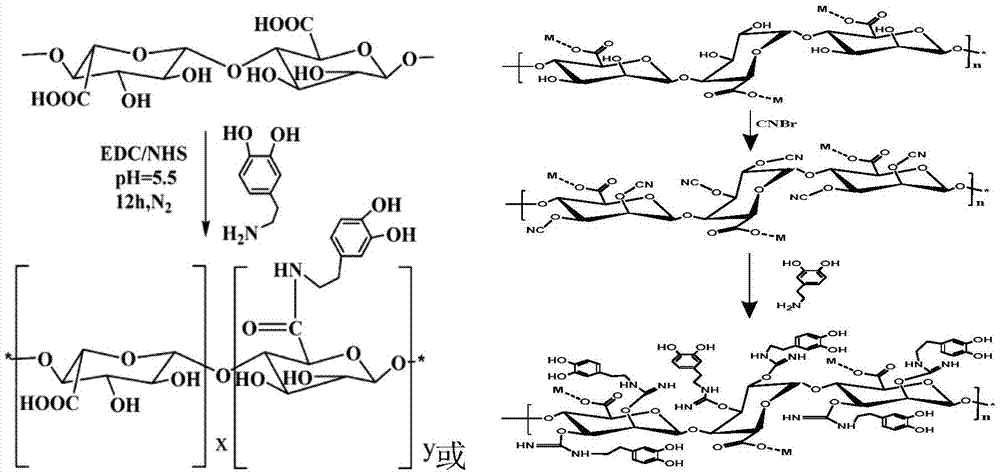

[0036] 1) Prepare sodium alginate solution: dissolve 2 g of sodium alginate in 200 ml of deionized water, add 2.132 g of MES, and adjust the pH value to about 5.5. Sodium alginate has a molecular weight of 320kDa and a G / M ratio of 55 / 45.

[0037] 2) Filter 1) solution to remove impurities.

[0038] 3) Add 1.936 g of water-soluble carbodiimide (EDC·HCl) and 1.116 g of N-hydroxysuccinimide (NHS) into the sodium alginate solution in step 2) and activate for 40 minutes.

[0039] 4) Add 1.92 g of dopamine hydrochloride as a solid to the sodium alginate solution in step 3), and react at room temperature for 12 hours under nitrogen protection.

[0040] 5) Add 400ml of ethanol dropwise to the sodium alginate solution in step 4) to obtain a precipitated sodium alginate solid. After washing with ethanol three times, the product was collected.

[0041] 6) The product obtained in step 5) was vacuum-dried to obtain dopamine-grafted sodium alginate with a grafting degree of 26%.

[004...

Embodiment 2

[0059] 1) Prepare sodium alginate solution: dissolve 2 g of sodium alginate in 200 ml of deionized water, add 2.132 g of MES, and adjust the pH value to about 5.5. Sodium alginate has a molecular weight of 320kDa and a G / M ratio of 55 / 45.

[0060] 2) Filter 1) solution to remove impurities.

[0061] 3) Add 1.936 g of EDC·HCl and 1.116 g of solid NHS into the sodium alginate solution in step 2), and activate for 40 minutes.

[0062] 4) Add 1.92 g of dopamine hydrochloride as a solid to the sodium alginate solution in step 3), and react at room temperature for 12 hours under nitrogen protection.

[0063] 5) Add 400ml of ethanol dropwise to the sodium alginate solution in step 4) to obtain a precipitated sodium alginate solid. After washing with ethanol three times, the product was collected.

[0064] 6) The product obtained in step 5) was vacuum-dried to obtain dopamine-grafted sodium alginate with a grafting degree of 26%.

[0065] 7) Dissolving the dopamine-grafted sodium ...

Embodiment 3

[0080] 1) Preparation of semi-dopamine-modified sodium alginate solution: dopamine-alginic acid was dissolved in physiological saline to prepare a 15 g / L galactosyl sodium alginate solution, which was sterile filtered. Among them, the dopamine-modified alginic acid has a molecular weight of 350kDa.

[0081] 2) Preparation of α-polylysine solution: α-polylysine was dissolved in physiological saline to prepare a 5 g / L α-polylysine solution, which was sterile filtered. Among them, the molecular weight of α-polylysine is 30kDa.

[0082] 3) Preparation of gel bath solution: Anhydrous calcium chloride was dissolved in deionized water to prepare a 11 g / L calcium chloride solution, which was sterilized by filtration.

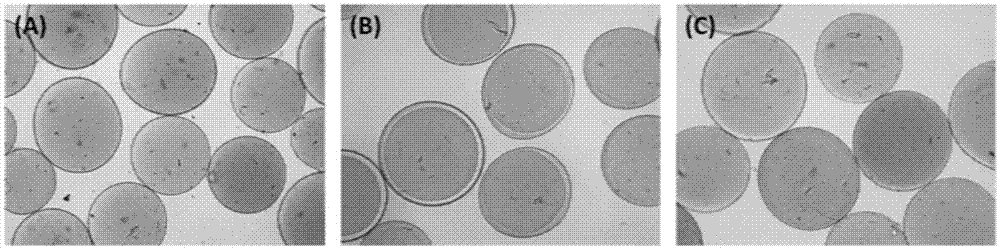

[0083] 4) Preparation of dopamine-modified calcium alginate / α-polylysine-embedded hydrogel microsphere carrier wrapped pig liver cells: take 3mL dopamine-modified sodium alginate solution, add 6*10^6 rat primary Hepatocytes were mixed evenly, and hydrogel microspheres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com