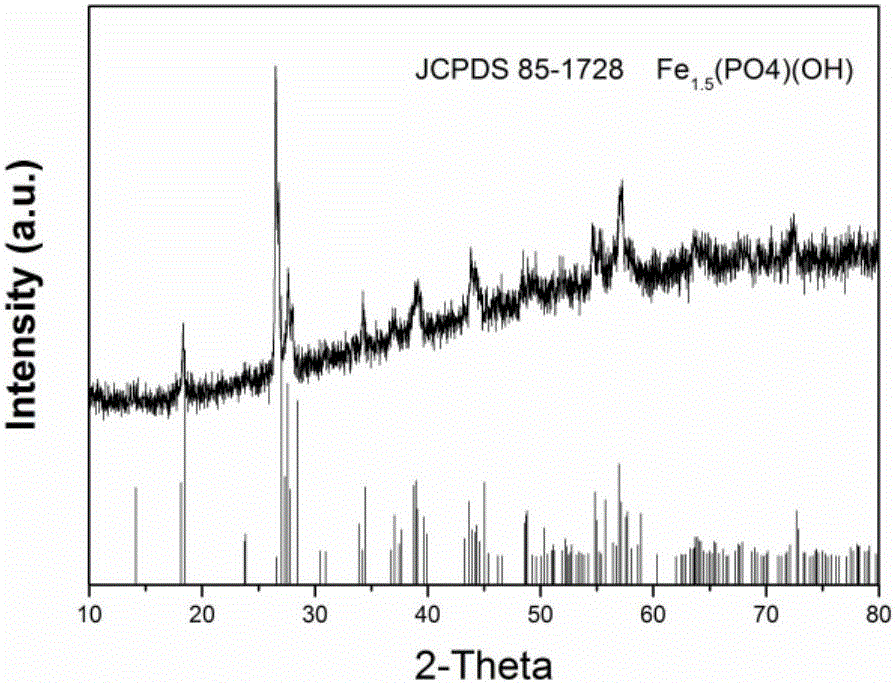

Method for preparing graphene-loaded Fe1.5(PO4)OH hollow octahedron lithium ion battery positive electrode material

A technology of ferric hydroxyphosphate and lithium ion battery, applied in the field of electrochemistry, can solve problems such as poor conductivity, and achieve the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a graphene-loaded iron hydroxyphosphate hollow octahedral lithium-ion battery positive electrode material, comprising the following steps:

[0025] 1) Dissolve commercially available graphene oxide in deionized water to form a solution of 1 to 5 mg / mL, and use an ultrasonic generator to sonicate for 2 to 6 hours at a power of 300 W to form a uniformly dispersed graphene oxide suspension, denoted as A ;

[0026] 2) Put analytically pure soluble ferrous salt (ferrous sulfate, ferrous chloride, etc.), urea, ammonium dihydrogen phosphate or diammonium hydrogen phosphate in a molar ratio of 1:1:0.5~1:1:5 Add to the mixed solution of deionized water and ethylene glycol (or glycerin), the volume ratio of water and ethylene glycol (or glycerin) is 5:1~5:5, stir for 10min-30min, then add to the suspension In A, configure mixed solution B, the concentration of iron salt in mixed solution B is 0.05-0.5mol / L, and the concentration of graphene oxide is 0.5-2....

Embodiment 1

[0031] 1) Dissolve commercially available graphene oxide in deionized water to form a solution of 1 mg / mL, and use an ultrasonic generator to sonicate for 3 hours at a power of 300 W to form a uniformly dispersed suspension of graphene oxide, which is designated as A;

[0032] 2) Add the analytically pure soluble ferrous ferrous salt ferrous sulfate, urea, and ammonium dihydrogen phosphate in a molar ratio of 1:1:0.5 to the mixed solution of deionized water and ethylene glycol, and the water and ethylene glycol The volume ratio is 5:1, stirred for 10 minutes, and then added to the suspension A to form a mixed solution. The concentration of iron salt is 0.05mol / L, and the concentration of graphene oxide is 0.5mg / mL, which is recorded as B ;

[0033] 3) Pour the mixed solution B prepared above into a microwave hydrothermal reactor with a filling degree of 60%, then seal the reactor, put it into a microwave hydrothermal reactor, and control the heating rate at 5°C / min. The react...

Embodiment 2

[0039] 1) Dissolve commercially available graphene oxide in deionized water to form a solution of 5 mg / mL, and use an ultrasonic generator to sonicate for 2 hours at a power of 300 W to form a uniformly dispersed suspension of graphene oxide, which is designated as A;

[0040] 2) Add analytically pure soluble ferrous ferrous salt ferrous sulfate, urea, and ammonium dihydrogen phosphate in a molar ratio of 1:1:1 to a mixed solution of deionized water and glycerin, and the volume ratio of water and glycerin is 5 : 3, stirred for 20min, then joined in the suspension A, configured into a mixed solution, the concentration of iron salt was 0.5mol / L, and the concentration of graphene oxide was a solution of 2.5mg / mL, denoted as B;

[0041] 3) Pour the mixed solution B prepared above into a microwave hydrothermal reactor with a filling degree of 40%, then seal the reactor, put it into a microwave hydrothermal reactor, and control the heating rate at 10°C / min. The reaction temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com